A computer circuit board soldering debugging device

A computer and circuit technology, which is applied in the field of computer circuit board soldering and debugging devices, can solve the problems of disordered circuit operation, inoperability, and virtual welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0023] In this application document, unspecified component models and structures are all prior art known to those skilled in the art, and those skilled in the art can set them according to the needs of the actual situation. In the embodiments of this application document No specific restrictions are made.

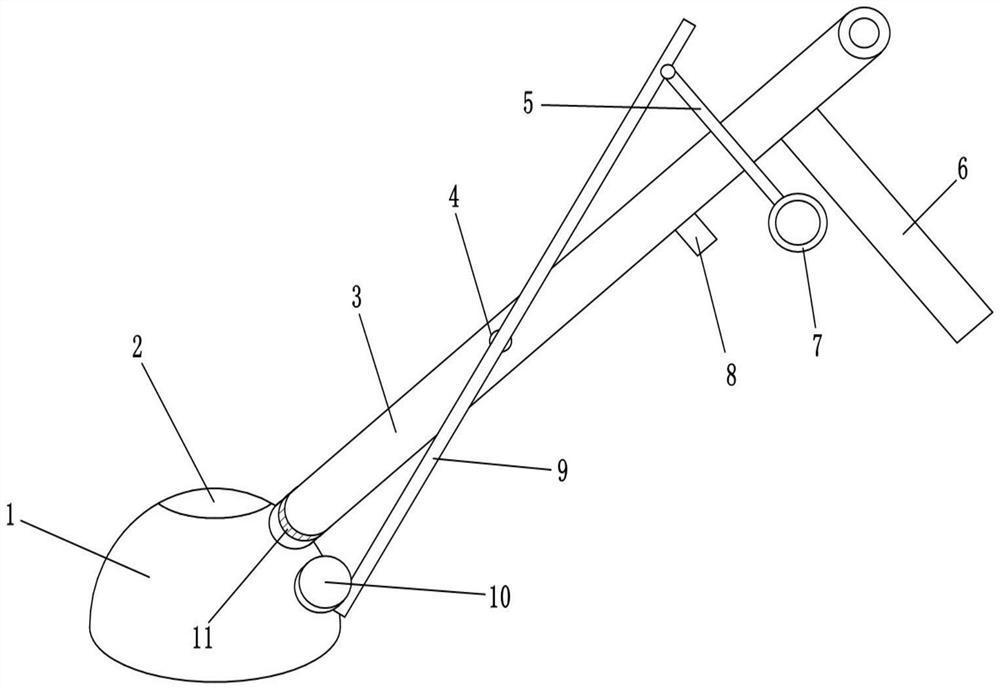

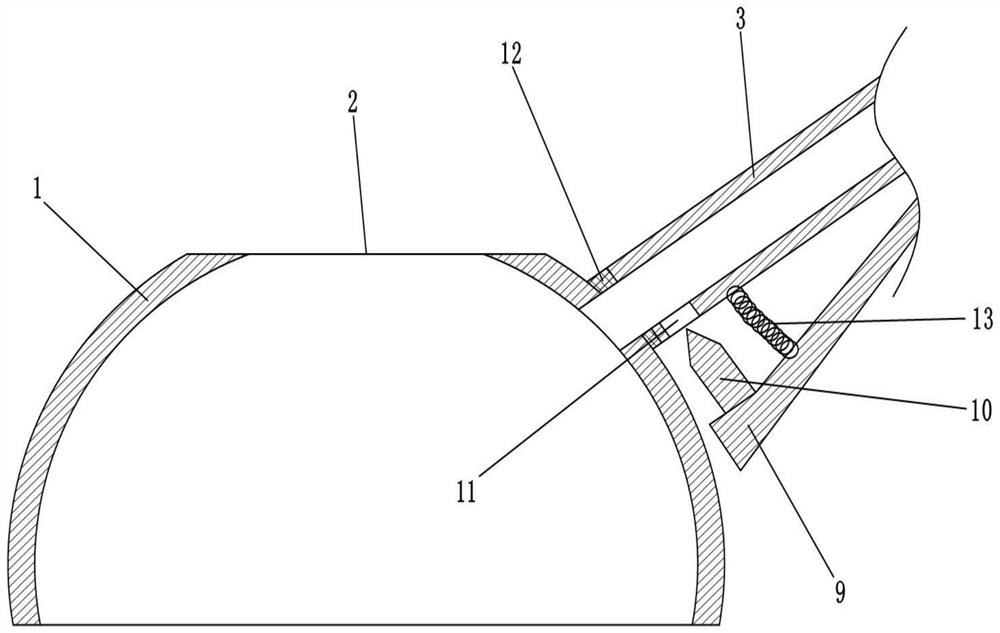

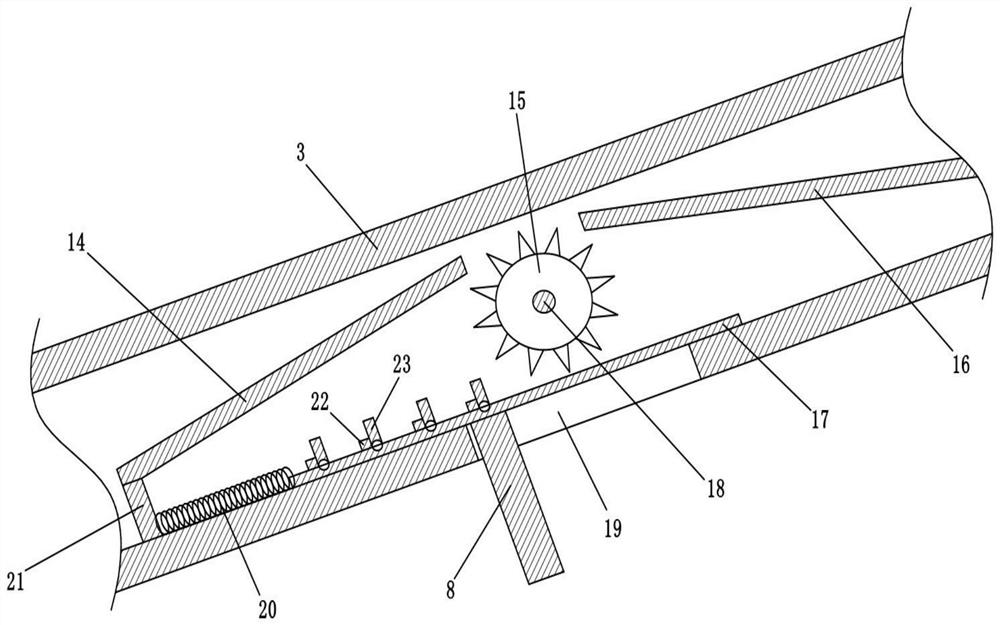

[0024] Specifically, such as Figure 1-4 As shown, the embodiment of the present invention provides a computer circuit board soldering debugging device, including: a hemispherical shell 1, a round tube 3, a cutter 10, and the like. Wherein, the material of the hemispherical shell 1 is iron, and its top is provided with a first port 2 for passing through the pins to be welded, and the side of its upper end is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com