Plug uninstalling and fastening wrench for railway locomotive maintenance

A technology for railway locomotives and plugs, which is applied in the direction of wrenches, railway auxiliary equipment, manufacturing tools, etc. It can solve the problems of virtual connections, small spaces, and using a lot of force, and achieve increased friction, simple structure, and strong force. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

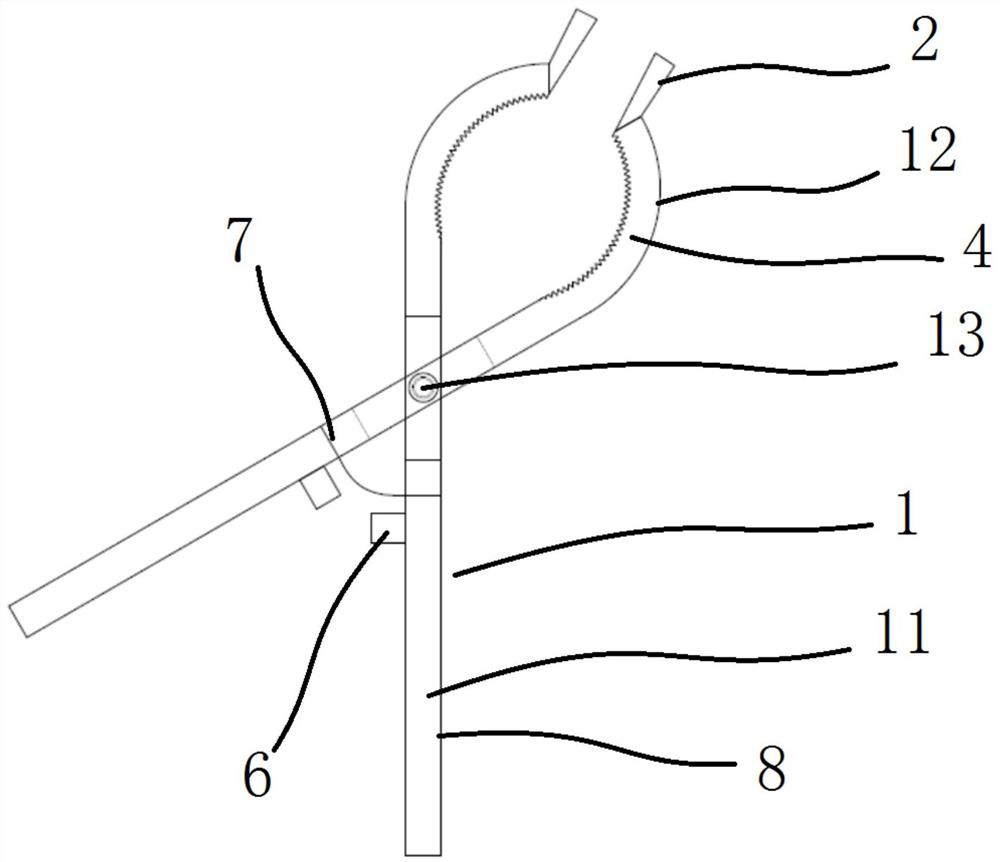

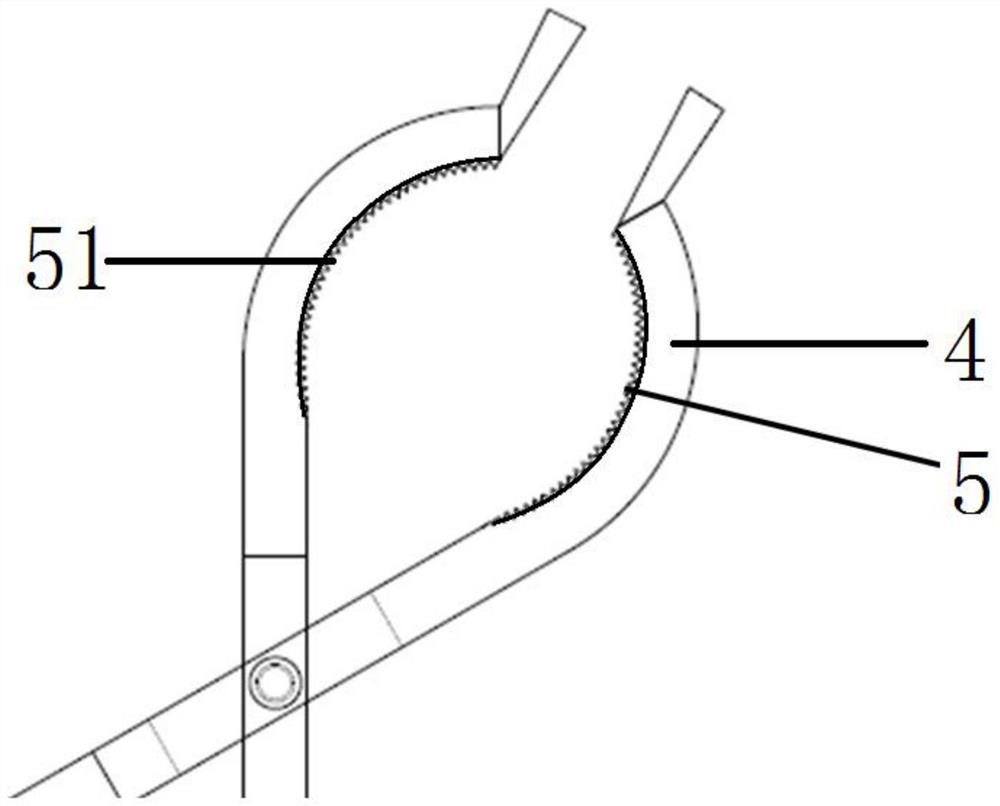

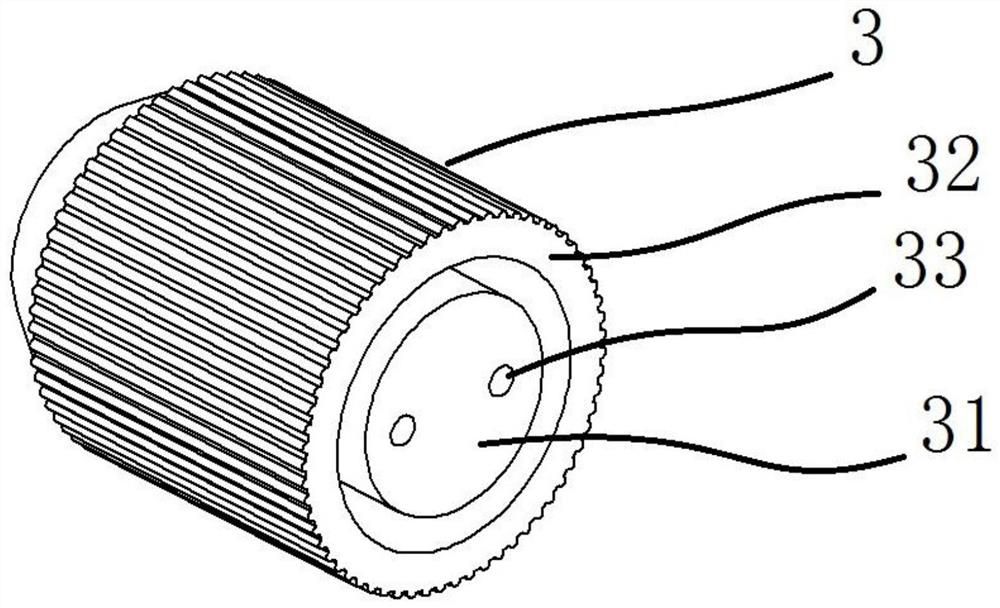

[0026] The structure of this scheme adopts the principle of leverage, which is similar to needle-nose pliers. The 11-point length of the pliers handle is longer than the 12-point length of the pliers head, which saves labor. Large, suitable for plugs of various sizes, the pliers head 12 is thinner so that it can be applied to more practical scenarios, for example, in the actual production process, there are often two aviation plugs to be disassembled 3 are far apart Recently, this situation is not convenient for workers to twist by hand, and they cannot use force. The pliers head 12 of this solution is thinner, and can be inserted between similar aviation plugs 3 to achieve the above ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com