Node connecting device for fabricated building structure

A technology of building structure and node connection, which is applied in the direction of building structure and construction, and can solve the problems affecting the stability of prefabricated building structures, insufficient connection strength at nodes, bolt deformation and stress, etc., to achieve good fixing effect and save assembly Time, the effect of ensuring the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

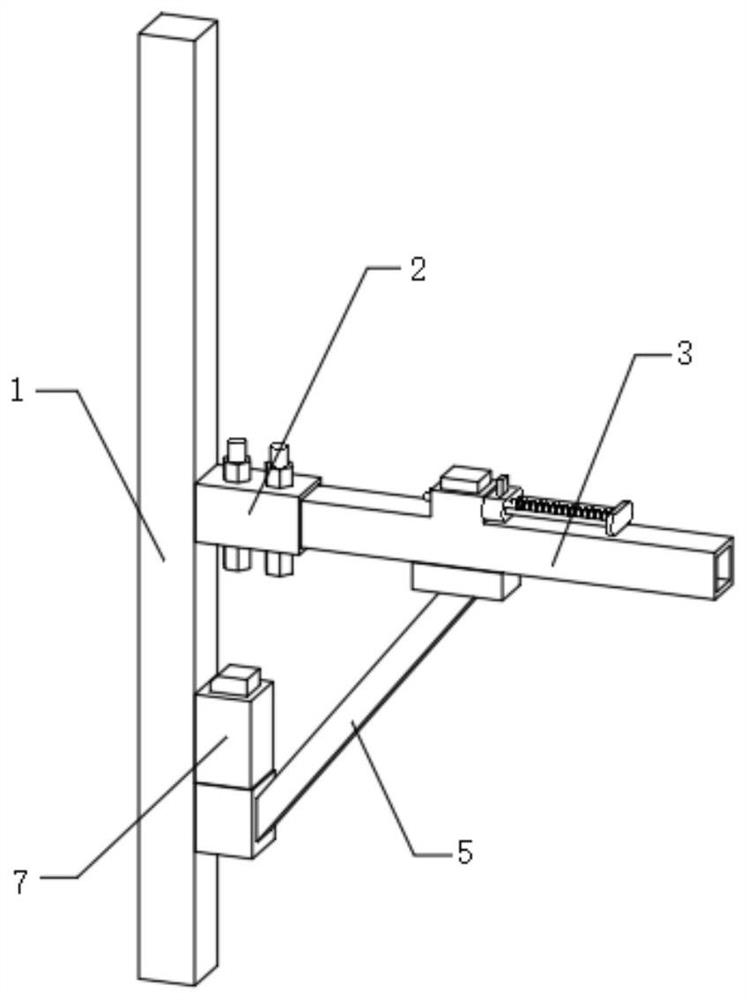

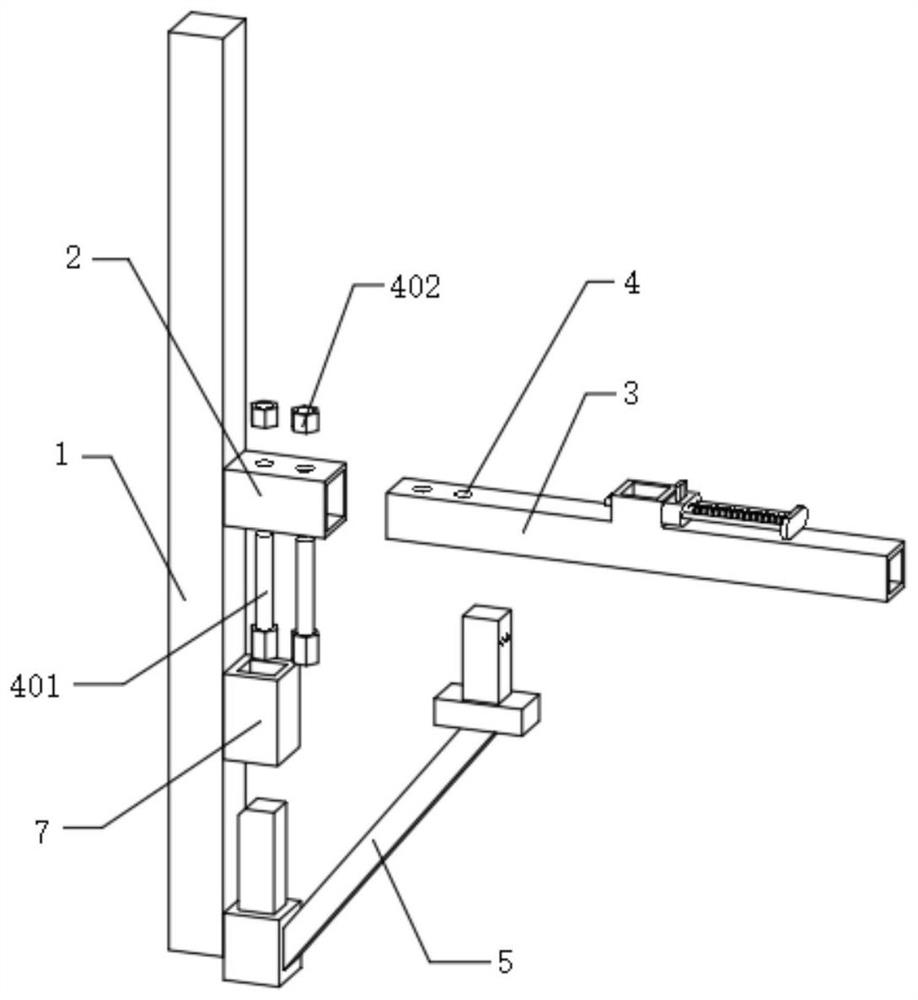

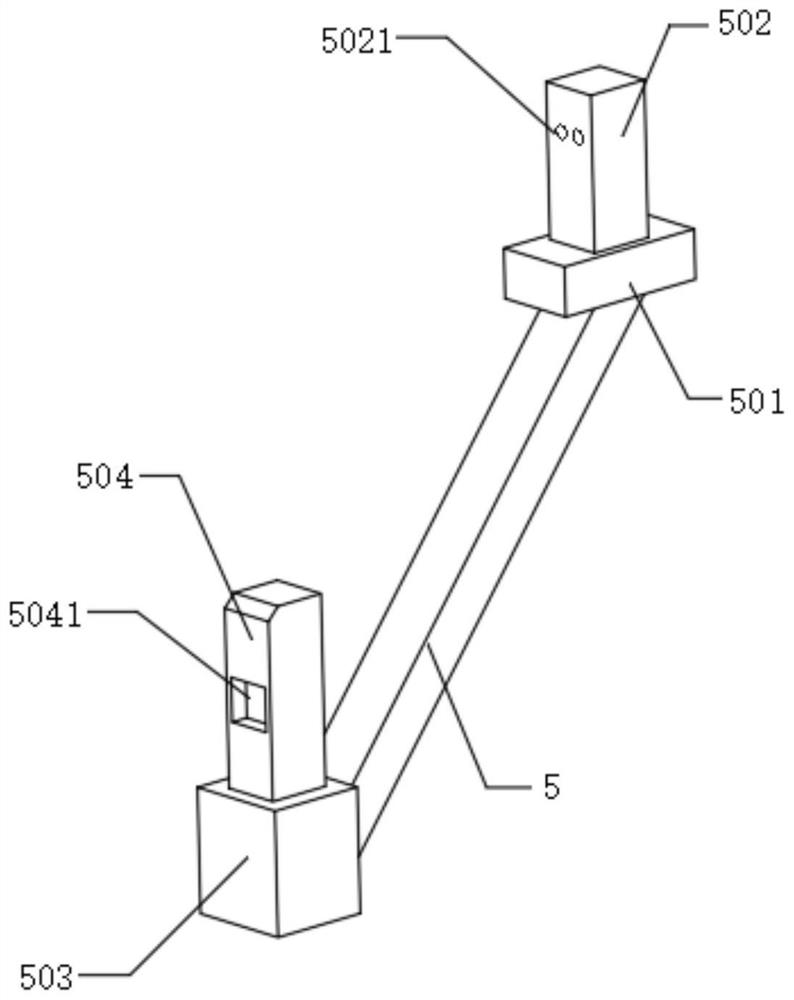

[0031] see Figure 1-8 As shown, the node connection device used for prefabricated building structures includes a column 1, the side wall of the column 1 is fixedly connected with a square tube seat 2, and the tube cavity of the square tube seat 2 is movably inserted with a cross bar 3, and the cross bar 3 There are two sets of fixing holes 4 on the top of the top, and fixing bolts 401 are movably inserted in the fixing holes 4. The fixing bolts 401 pass through the square tube seat 2 and the fixing holes 4 and extend upwards and are screwed with fixing nuts 402. The upright column 1 and the cross bar 3, a reinforcing rib 5 is fixedly installed, the top of the reinforcing rib 5 is fixedly connected with a top block 501, and the top of the top block 501 is fixedly connected with a first post 502, and the side wall of the first post 502 is provided with two sets of locking The hole 5021, the top of the cross bar 3 is fixedly connected with the first square sleeve 6, the first po...

Embodiment 2

[0040] see Figure 1-8 As shown, the node connection device used for prefabricated building structures includes a column 1, the side wall of the column 1 is fixedly connected with a square tube seat 2, and the tube cavity of the square tube seat 2 is movably inserted with a cross bar 3, and the cross bar 3 There are two sets of fixing holes 4 on the top of the top, and fixing bolts 401 are movably inserted in the fixing holes 4. The fixing bolts 401 pass through the square tube seat 2 and the fixing holes 4 and extend upwards and are screwed with fixing nuts 402. The upright column 1 and the cross bar 3, a reinforcing rib 5 is fixedly installed, the top of the reinforcing rib 5 is fixedly connected with a top block 501, and the top of the top block 501 is fixedly connected with a first post 502, and the side wall of the first post 502 is provided with two sets of locking The hole 5021, the top of the cross bar 3 is fixedly connected with the first square sleeve 6, the first po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com