Evaporator self-cleaning system and clothes dryer

An evaporator and self-cleaning technology, applied in the field of clothes drying, can solve problems such as affecting drying performance and dirt, and achieve the effect of improving drying performance and cleaning the evaporator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The core of the present invention is to provide an evaporator self-cleaning system and a clothes dryer, so as to improve the drying performance of the clothes dryer.

[0038] In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

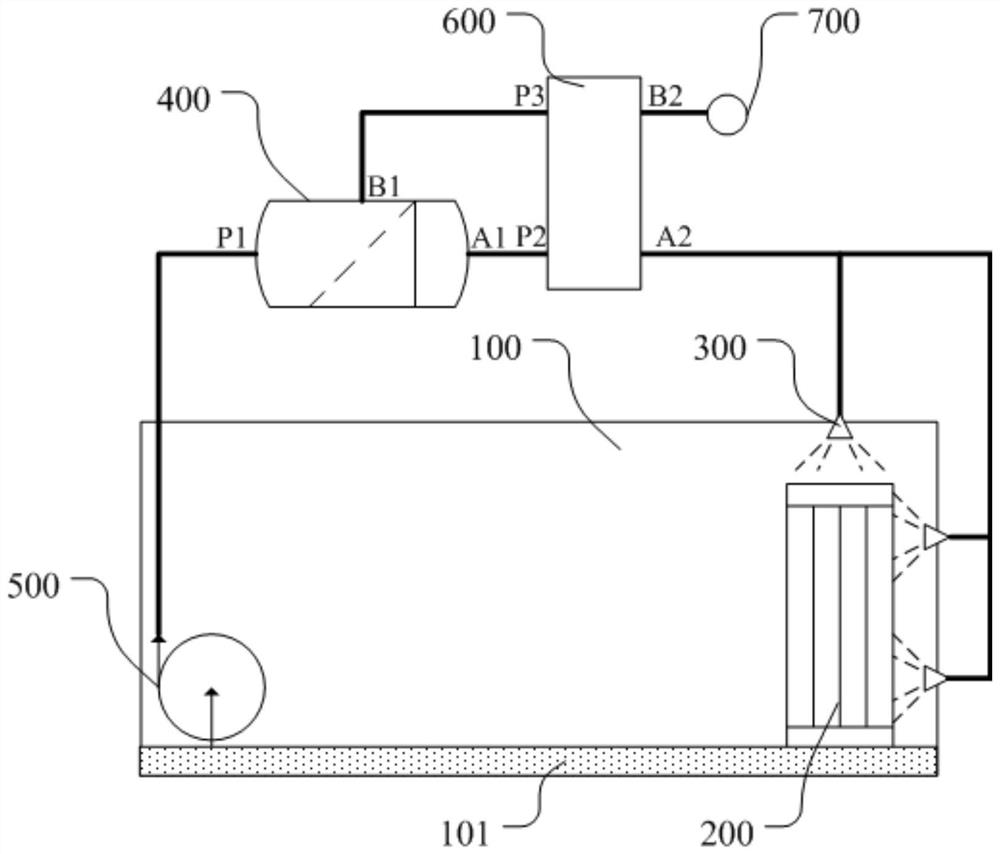

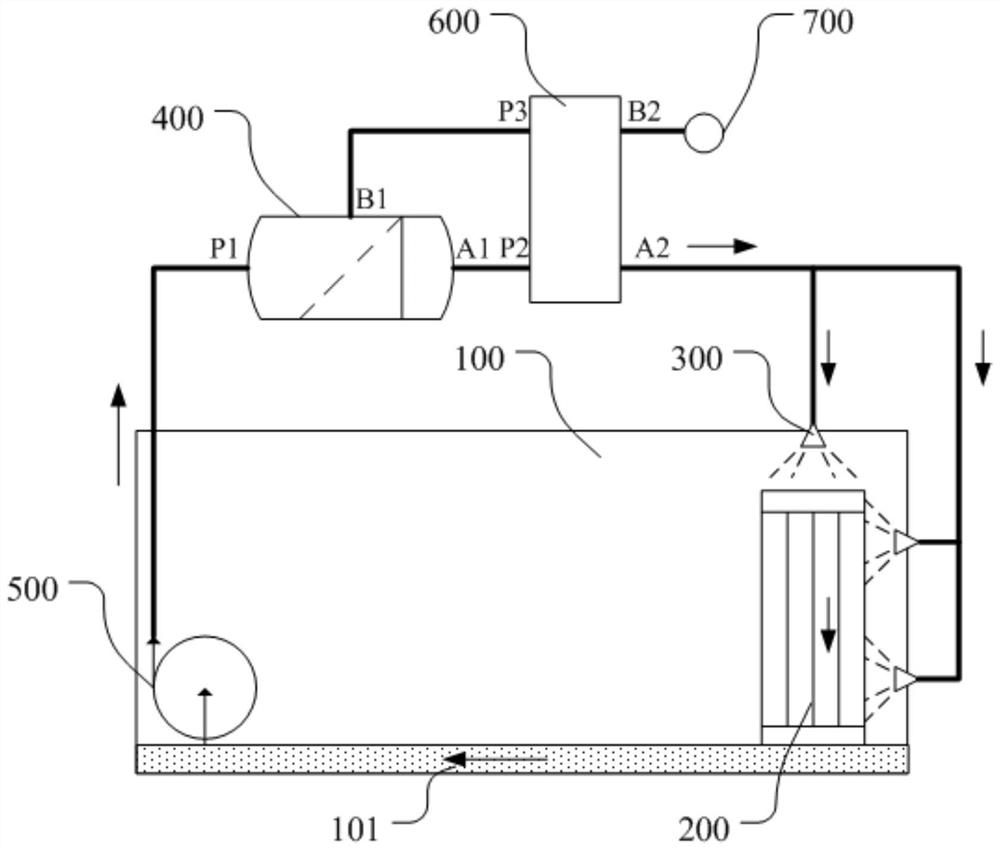

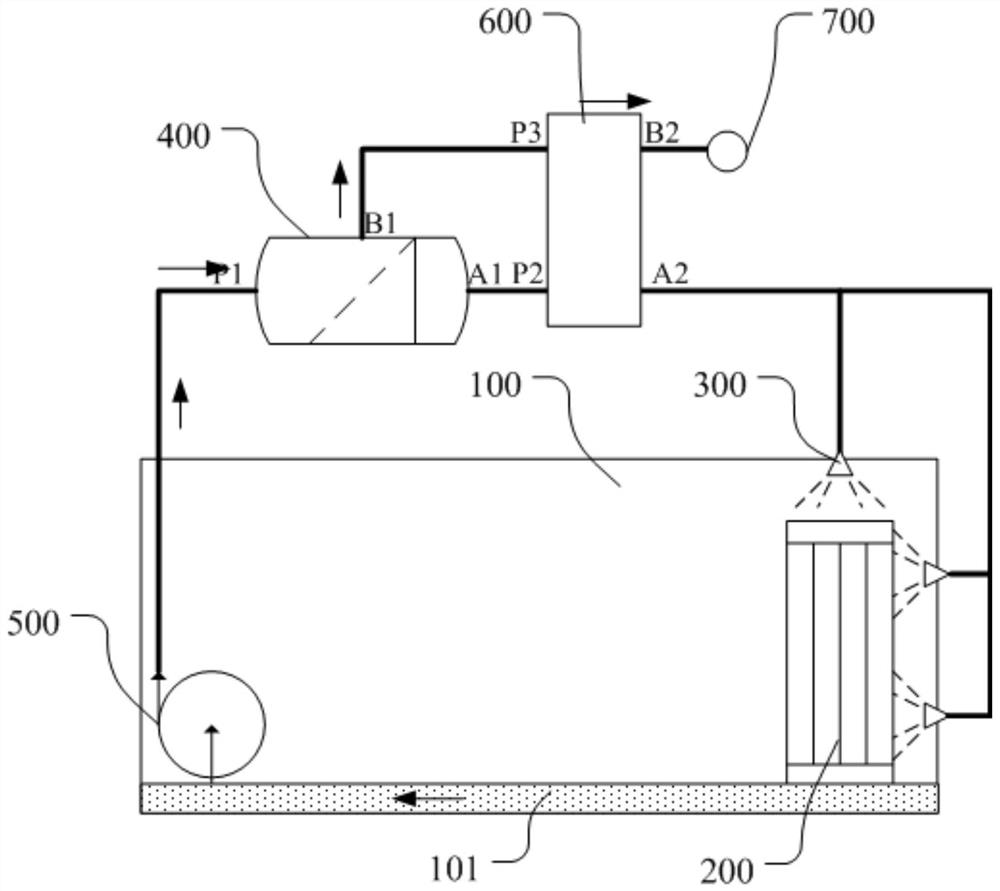

[0039] To do this, see Figure 1 to Figure 6 , the evaporator self-cleaning system in the embodiment of the present invention includes:

[0040] The base 100, the inside of the base 100 is used to arrange the evaporator 200, the base 100 is provided with a water storage tank 101 and a flushing nozzle 300 for flushing the evaporator 200;

[0041] A filter 400, the filter 400 is used to filter impurities in the flushing liquid;

[0042] A drainage pump 500, the drainage pump 500 is used to pump the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com