Contact finger assembly

A technology of touch fingers and components, applied in the direction of contact meshing, contact shell/screen, etc., can solve the problems of small shrinkage force, poor contact between the contact finger and the contact, etc. Pressure, the effect of improving the flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

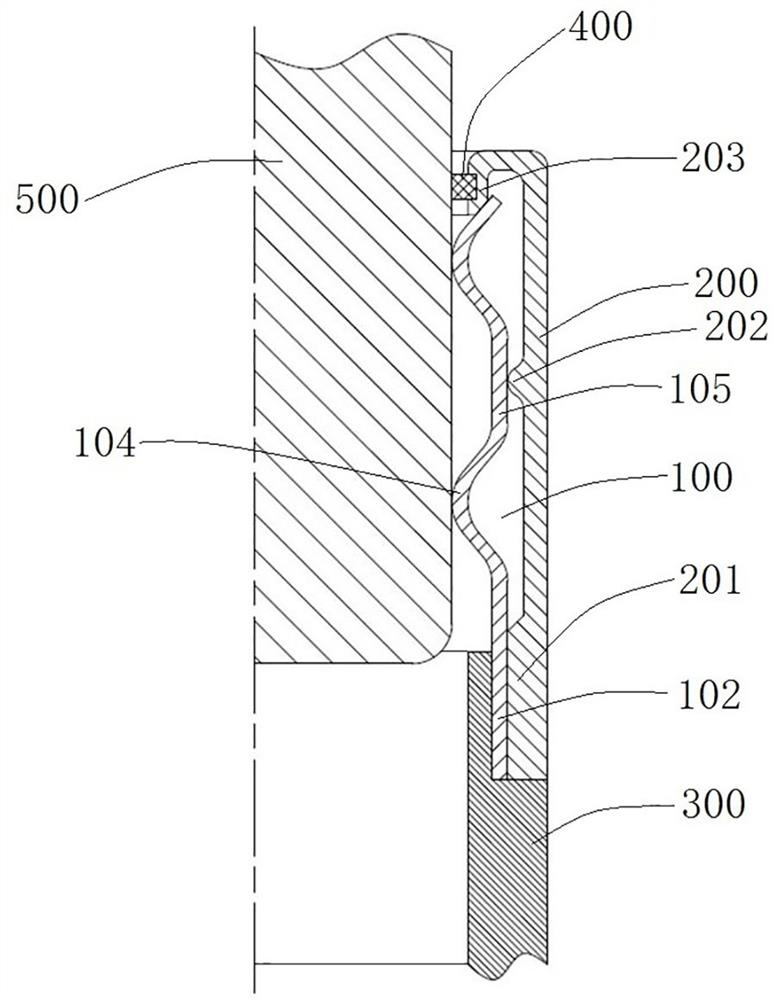

[0039] Such as Figure 1 to Figure 4 As shown, the finger assembly includes a support 300 , a contact finger 100 fixed on the support 300 , and a shield 200 , and the shield 200 covers the outside of the contact finger 100 .

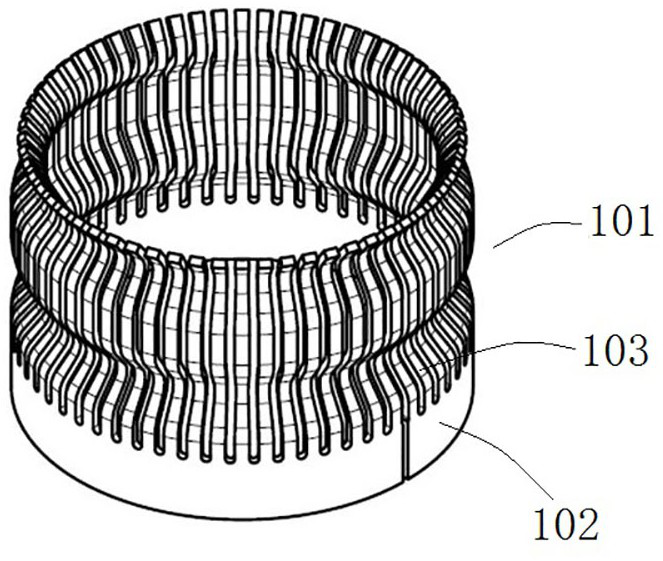

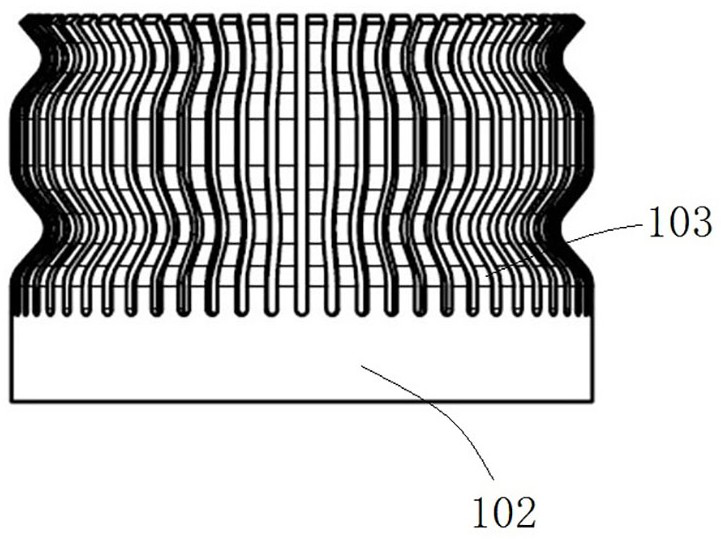

[0040] Such as figure 1 As shown, the support 300 is an annular conductor. The structure of the finger 100 is as follows: Figure 2 to Figure 4 As shown, the stylus 100 includes a stylus 101, and the stylus 101 is an integrally formed part with a gap, specifically, it can be formed by sheet metal or stamping from a plate or pipe. The contact finger 101 includes an arc-shaped base 102, and the central axis of the arc-shaped base 102 extends up and down. The contact finger 101 also includes a plurality of circumferentially spaced elastic contact pieces 103 above the arc-shaped base 102. The elastic contact pieces 103 The upper end is a cantilevered end, and the elastic contact piece 103 can elastically swing.

[0041] The specific structure of the elas...

specific Embodiment 2

[0048] Such as Figure 5 As shown, the difference from Embodiment 1 is that in Embodiment 1, there are two raised segments, while in this embodiment, the raised segments 104 have three layers arranged at intervals up and down, and two adjacent raised segments Straight line segments 105 are arranged between 104 . An annular protrusion 202 is provided on the shielding case 200 corresponding to each straight line segment 105 . In use, the three layers of raised segments 104 are in common contact with the contact 500 to achieve conductive communication.

[0049] In actual use, when designing the number of layers of the raised section 104 , it is necessary to take into account the contact pressure and the flow requirements to select reasonably. In actual use, the number of layers of the raised section 104 can be increased or decreased according to the actual situation.

Embodiment 1

[0051] In Embodiment 1, the stylus is composed of one stylus. In this embodiment, there may be two or more contact fingers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com