Manufacturing method of flavored cigar with hollow groove inside

A production method and cigar technology, applied in the manufacture of cigars, tobacco, etc., can solve the problems of high smoke concentration, short smoldering time, and large suction resistance, etc., to achieve long smoldering time, easy ignition, and smoking smooth suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

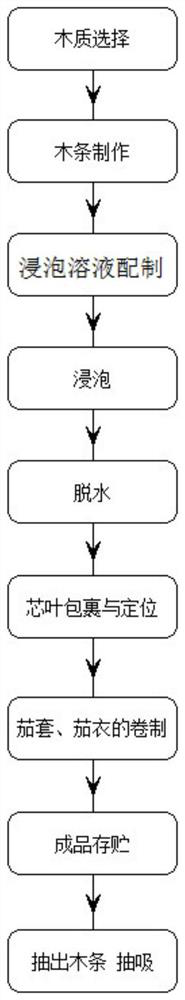

[0020] A method of making a flavored cigar with an empty slot inside, such as figure 1 shown, including the following steps:

[0021] S1. Choose cedar wood and cut it into strips with a diameter of 2mm and a length of 50mm.

[0022] S2. Place the wooden strips cut in step S1 in a soaking solution composed of 10wt% guaiac wood tincture, 5wt% plum tincture, 5wt% vanilla bean tincture, 40wt% rum, and 40wt% whiskey, And in a closed container, heat at 50°C for 12 hours, and then dry in the shade naturally to reduce the moisture content of the wood strips to 14%.

[0023] S3. Among the core leaves used in cigars, select a core leaf with better elasticity, thicker thickness, and complete sheet shape. Among them, the better elasticity and thicker thickness are the choices when rolling conventional cigars , does not require a definite data index, it is only the subjective choice of the production staff, and it is wrapped with the wooden strip with a well-controlled moisture content i...

Embodiment 2

[0027] A method of making a flavored cigar with an empty slot inside, such as figure 1 shown, including the following steps:

[0028] S1. Choose cedar wood and cut it into strips with a diameter of 4mm and a length of 200mm.

[0029] S2. Place the wooden strips cut in step S1 in a soaking solution composed of 10wt% guaiac wood tincture, 5wt% plum tincture, 5wt% vanilla bean tincture, 40wt% rum, and 40wt% whiskey, And in a closed container, heat at 50°C for 15 hours, and then dry in the shade naturally to reduce the moisture content of the wood strips to 16%.

[0030] S3. Among the core leaves used in cigars, select a core leaf with better elasticity, thicker thickness, and complete sheet shape. Among them, the better elasticity and thicker thickness are the choices when rolling conventional cigars , does not require a definite data index, it is only the subjective choice of the production staff, and it is wrapped around the wooden strip with a well-controlled moisture conten...

Embodiment 3

[0034] A method of making a flavored cigar with an empty slot inside, such as figure 1 shown, including the following steps:

[0035] S1. Choose cedar wood and cut it into strips with a diameter of 3mm and a length of 100mm.

[0036] S2. Place the wooden strips cut in step S1 in a soaking solution composed of 10wt% guaiac wood tincture, 5wt% plum tincture, 5wt% vanilla bean tincture, 40wt% rum, and 40wt% whiskey, And in a closed container, heat at 50°C for 20 hours, and then dry in the shade naturally to reduce the moisture content of the wood strips to 15%.

[0037] S3. Among the core leaves used in cigars, select a core leaf with better elasticity, thicker thickness, and complete sheet shape. Among them, the better elasticity and thicker thickness are the choices when rolling conventional cigars , does not require a definite data index, it is only the subjective choice of the production staff, and it is wrapped around the wooden strip with a well-controlled moisture conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com