Gas-assisted mechanism and blowing method

A gas-assisted and gas-circuit technology, which is applied in the field of gas-assisted mechanisms and blowing, can solve the problems of high-pressure gas not being discharged in time, bursting, product strain, etc., and achieve the effect of avoiding pressure difference, not easy to strain, and avoiding bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

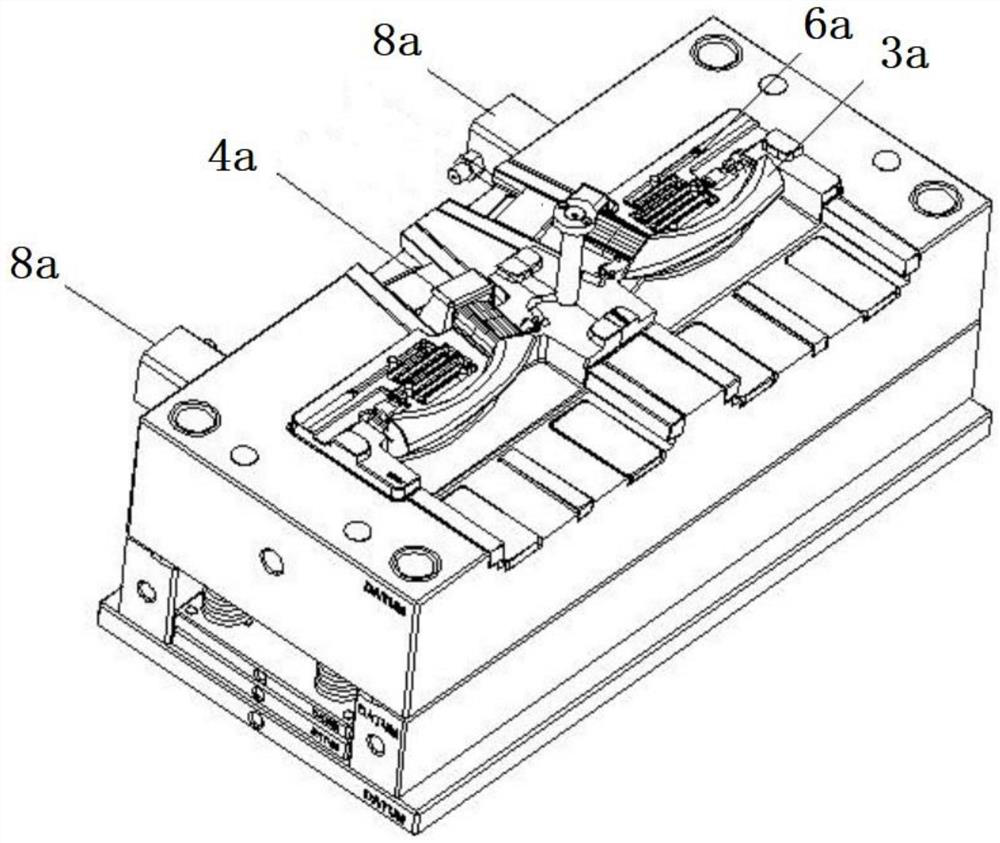

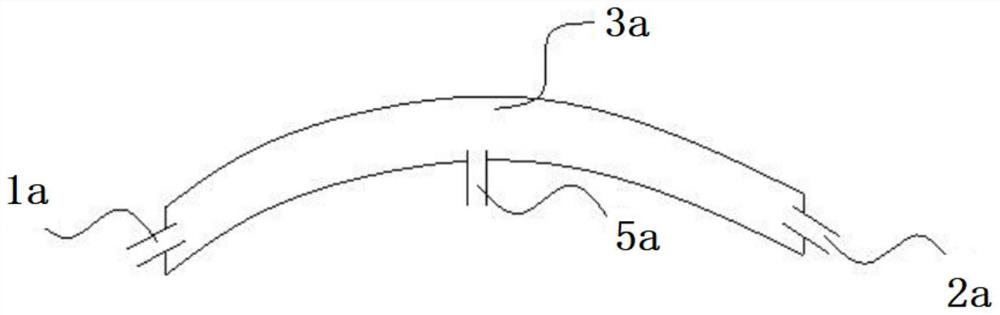

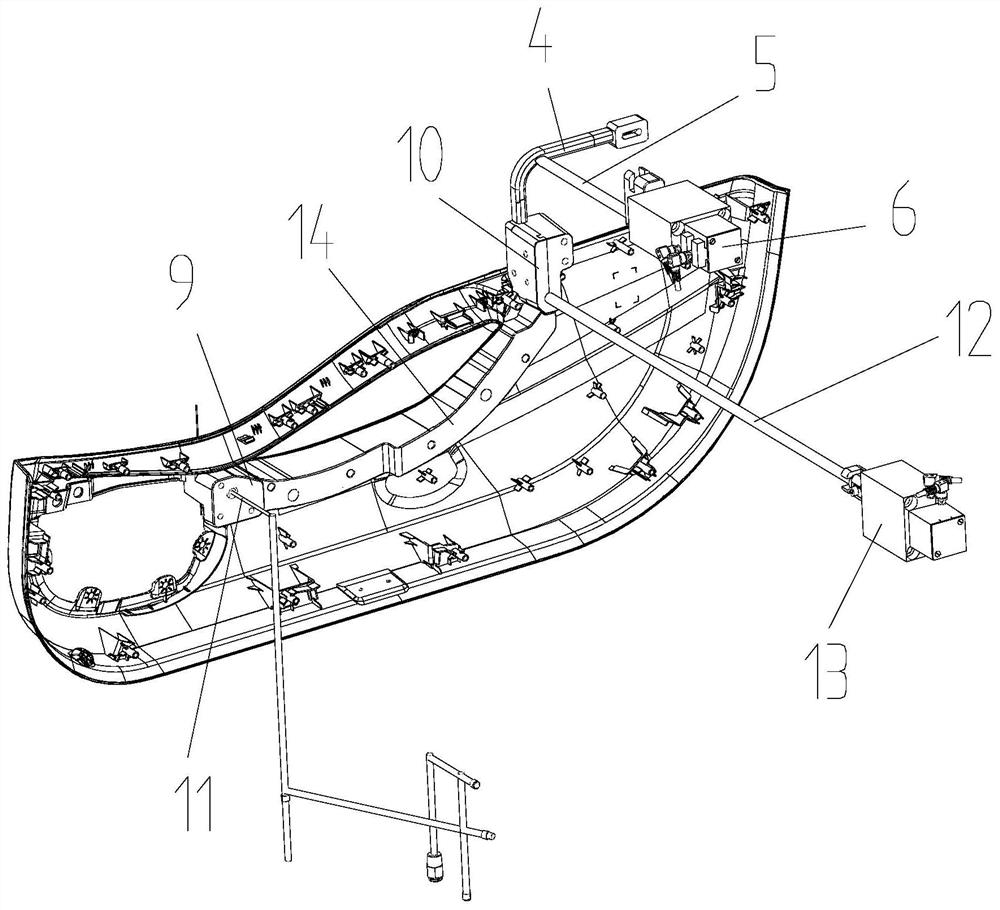

[0027] A gas-assisted mechanism, comprising a gas-assisted channel 3 with a feed port 1 at one end and a discharge port 2 at the other end, the discharge port 2 communicates with an overflow channel 4, and also includes a deflated ejector pin 5 and The first linear drive device 6, the deflated push rod 5 is arranged at the overflow channel 4, the first linear drive device 6 is connected with the deflated push rod 5, and is used for piercing or pulling out the deflated push rod 5 The overflow channel 4, the front end of the deflated mandrel 5 is tapered to form a knife portion 7, and the side of the deflated mandrel 5 near the knife portion 7 is cut off in the axial direction to form a vent channel 8 .

[0028] The gas-assisted mechanism of the present invention is provided with a deflated ejector pin 5 at the position where the overflow channel 4 is located, and uses the tapered knife portion 7 of the deflated ejector pin 5 to pierce into the cold material of the overflow chan...

Embodiment 2

[0032] A blowing method of a gas-assisted mechanism, the method is based on the gas-assisted mechanism in embodiment 1, and it comprises the following steps:

[0033] (1) Close the discharge port 2, and inject molten material through the feed port 1 for injection molding;

[0034] (2) Before the product is completely cooled after injection molding, open the discharge port 2, blow in nitrogen through the inlet needle 11, and blow out the excess material through the gas-assisted channel 3;

[0035] (3) The cold material blown out in the gas-assisted channel 3 overflows into the overflow channel 4, and the knife portion 7 of the deflated push rod 5 is driven by the first linear drive device 6 to penetrate the cold material in the overflow channel 4, so as to The piercing part of the cold material forms a weak point, and the high-pressure gas in the hollow part of the gas-assisted channel 3 is released from the weak point of the cold material, and is safely discharged out of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com