Non-woven fabric rolling conveying mechanism

A technology of transmission mechanism and non-woven fabric, which is applied in the direction of transportation and packaging, winding strips, thin material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. The components of the embodiments of the invention generally described and illustrated in the figures herein may be arranged and designed in a variety of different configurations.

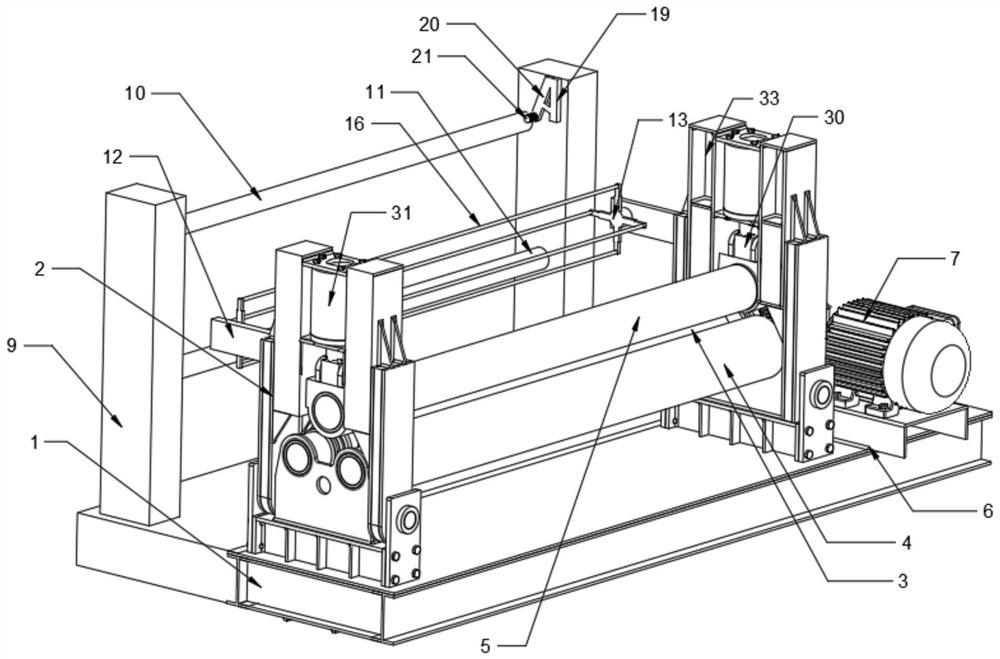

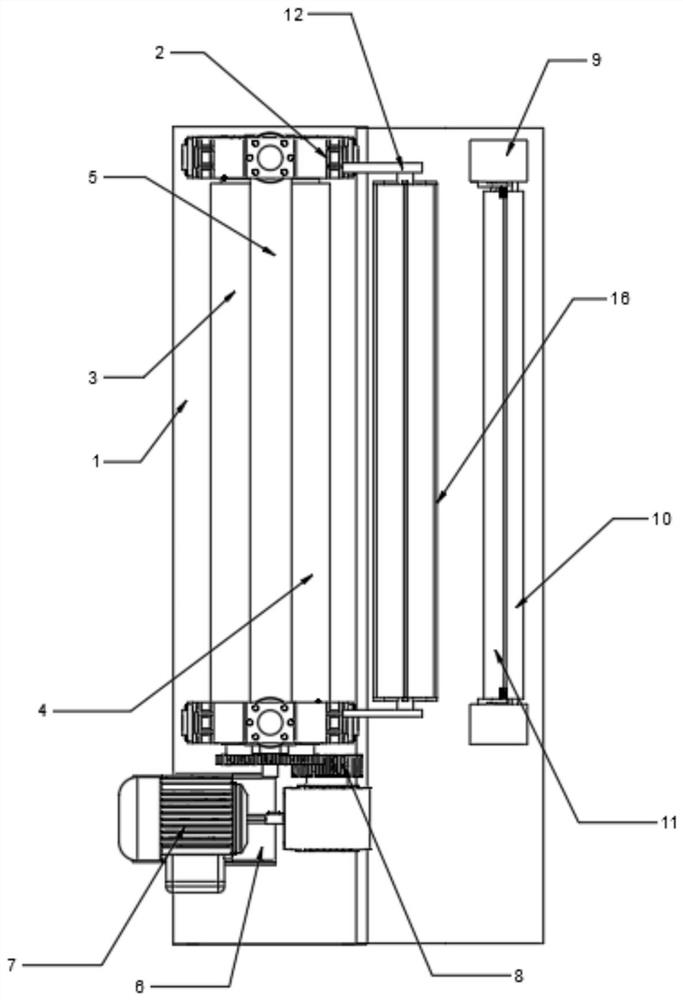

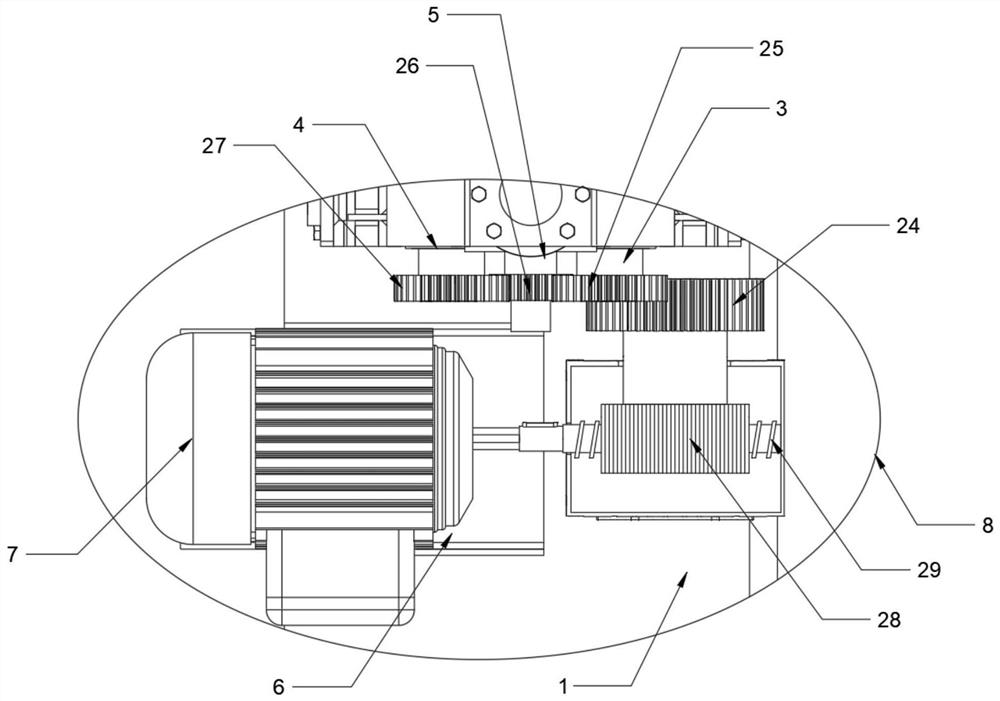

[0025] First, refer to Figure 1 to Figure 7 A roll conveying mechanism for a nonwoven fabric according to an embodiment of the present invention will be specifically described.

[0026] A rolling transmission mechanism for non-woven fabrics, comprising a base 1 and a support 2, the first lower roller 3 and the second lower roller 4 are connected symmetrically in the support 2, and the support 2 is located between the first lower roller 3 and the second lower roller The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com