Prestressed anchoring device for concrete bridge and construction method of prestressed anchoring device

An anchoring device and bridge construction technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems that it is difficult to ensure that the tensile strength of carbon fiber cloth is fully utilized, the construction efficiency is low, and the structure of carbon fiber cloth tensile anchors is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

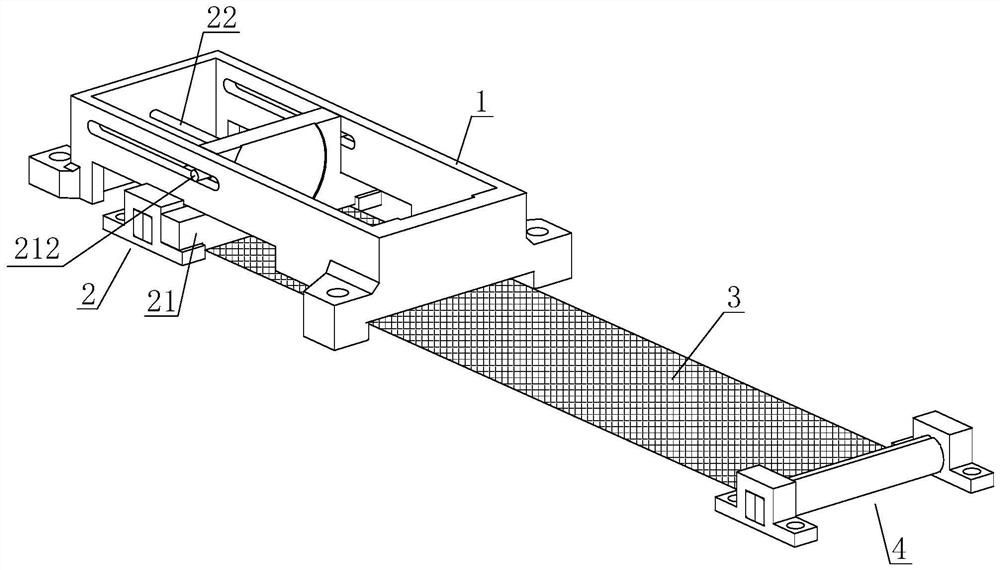

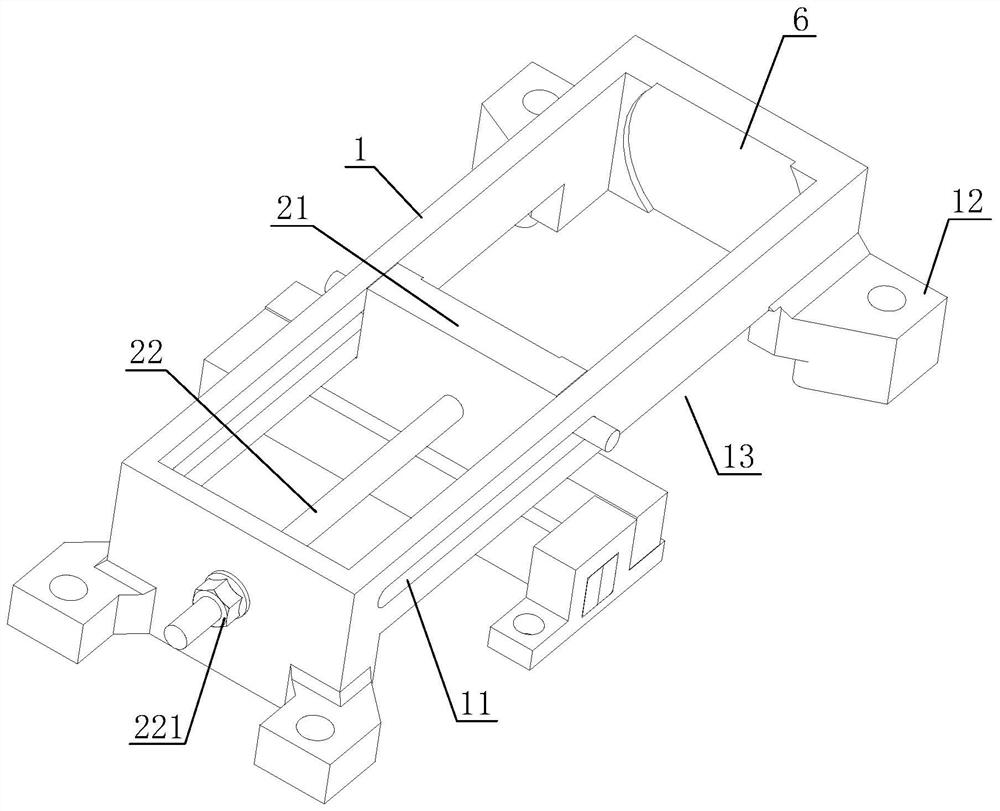

[0032] The technical scheme adopted in this embodiment is as follows: Figure 1~4 As shown, it is a prestressed anchoring device for a concrete bridge, which includes a frame assembly installed at the bottom of the bridge, a fixed part 4, a tension part 2, and a bridge construction between the fixed part 4 and the tension part 2. Surface carbon fiber cloth3.

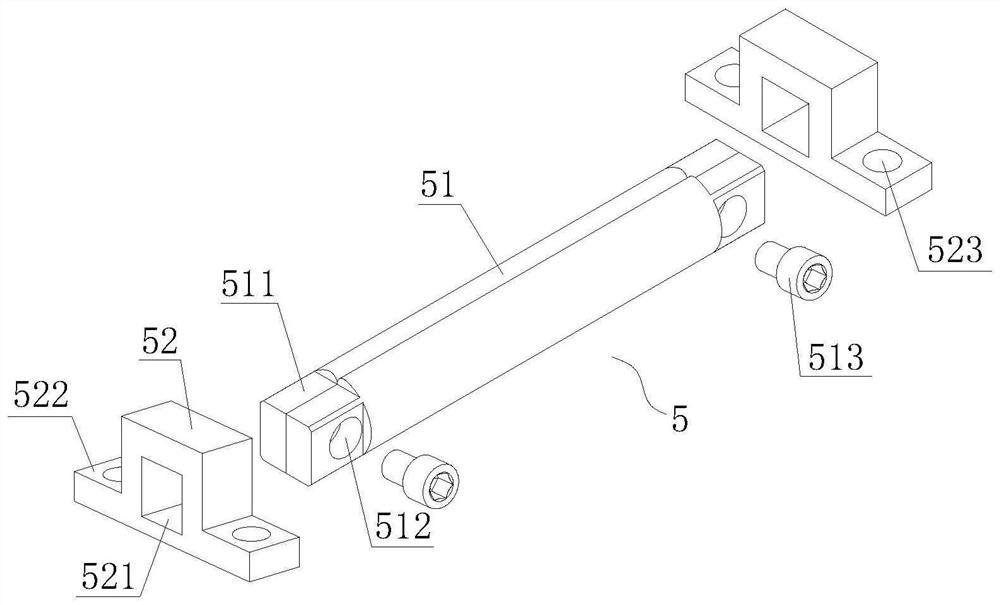

[0033] Specifically, both the fixed part 4 and the tension part 2 include such as image 3The clamping assembly 5 shown, the clamping assembly 5 includes a cloth clamping shaft 51 and a fixed base, two cloth clamping shafts 51 are provided, and the two clamping cloth shafts 51 are spliced along the axial direction to form a cylinder, and the carbon fiber cloth 3 ends Clamped at the junction of the two clamping shafts 51; the fixed base is located at both ends of the two clamping shafts 51, clamping the spliced two clamping shafts 51 and limiting the circumferential rotation of the two clamping shafts 51, the fixed b...

Embodiment 2

[0038] Present embodiment is the construction method of embodiment 1 concrete bridge prestressed anchorage device, comprises the following steps:

[0039] S1. Carry out pretreatment on the bridge construction surface, clamp one end of the carbon fiber cloth between the two clamping shafts of the fixed part, rotate one and a half weeks along the circumferential direction of the clamping shaft to fix the carbon fiber cloth on the clamping shaft, and then clamp the cloth Install fixed bases at both ends of the shaft, and anchor the fixed bases to the bridge construction surface through chemical anchor bolts;

[0040] S2. Clamp the other end of the carbon fiber cloth between the two clamping shafts of the tensioning part, and rotate the clamping shaft for one and a half weeks to fix the carbon fiber cloth on the clamping shaft, and then install a fixed base at both ends of the clamping shaft , place the tensioned top plate on the anchoring flange of the fixed base, and finally ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com