Magnetic attraction patch photoresist management method and system based on RFID tag management

An RFID label and management method technology, applied in the field of magnetic suction patch photoresist management methods and systems, can solve the problems of generating air bubbles, difficult to read and manage photoresist information in time, shaking of photoresist in the bottle, etc., and achieve accurate The effect of reading and avoiding RFID tag information interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

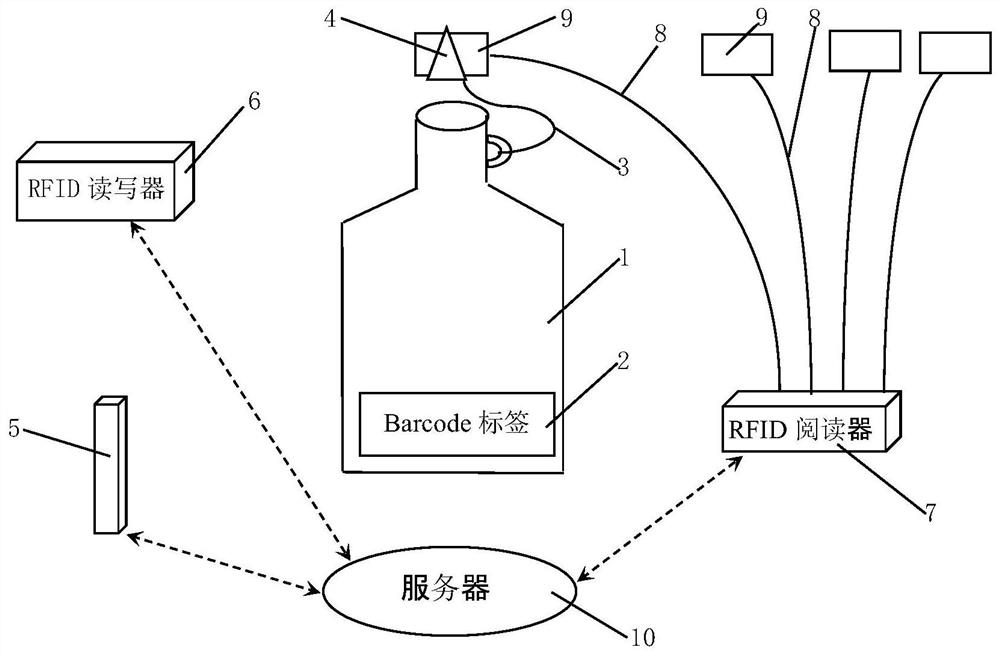

[0019] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically explain the magnetic patch photoresist management method and system based on RFID tag management of the present invention in conjunction with the accompanying drawings.

[0020]

[0021] Such as figure 1 As shown, this embodiment provides a magnetic patch photoresist management system based on RFID tag management, the system includes: RFID tag 4, barcode identification handheld terminal 5, RFID reader 6, RFID reader 7, server 10 , Management terminal (not shown in the figure).

[0022] The Barcode label 2 is attached to the body of the photoresist bottle 1 , usually one or more Barcode labels 2 may be attached to the body of a photoresist bottle 1 . The barcode recognition handheld terminal 5 is used to scan the Barcode label 2 to read the Barcode label information.

[0023] The RFID tag 4 is bound on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com