Die, device and method for producing amorphous alloy tube

An amorphous alloy and preparation device technology, applied in the field of materials, can solve the problems of poor forming accuracy, difficulty in preparing amorphous alloy pipes, and difficulty in preparing thick-walled or curved amorphous alloy pipes, so as to improve the ability of forming amorphous alloys Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Mold and apparatus for preparing amorphous alloy tubes.

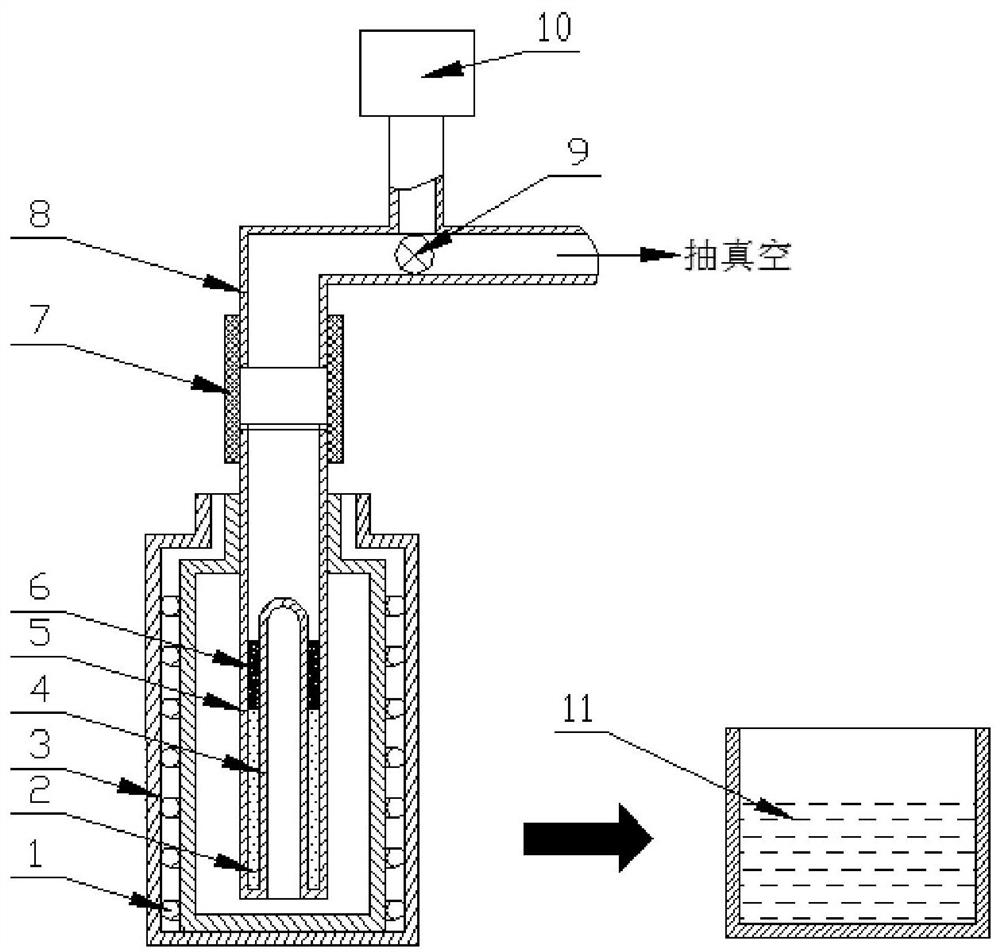

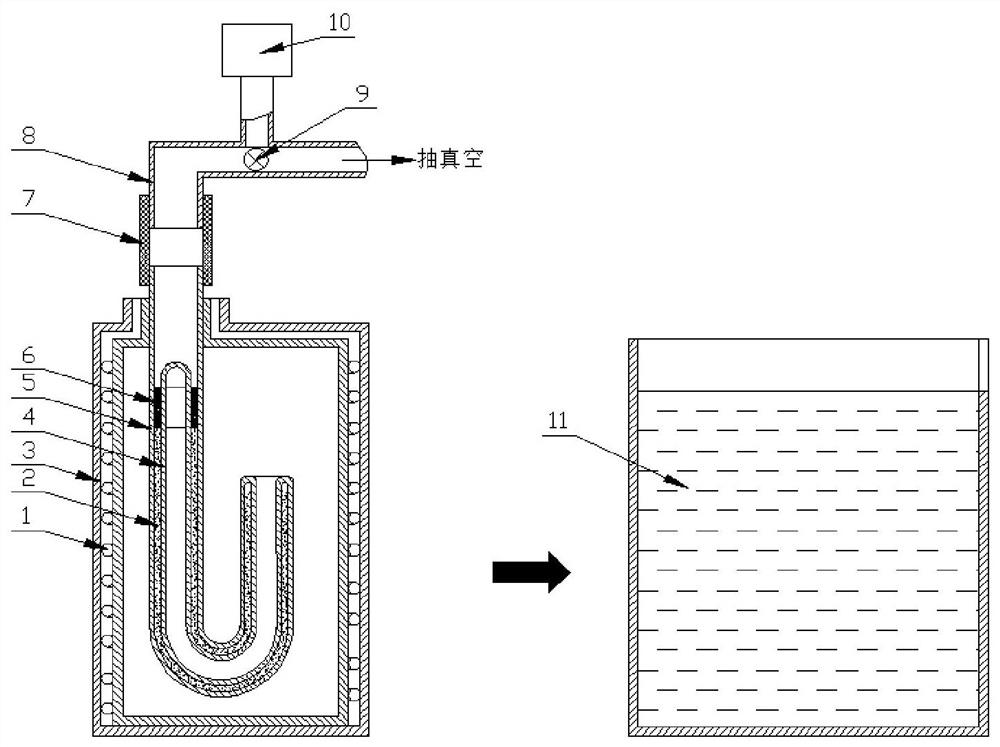

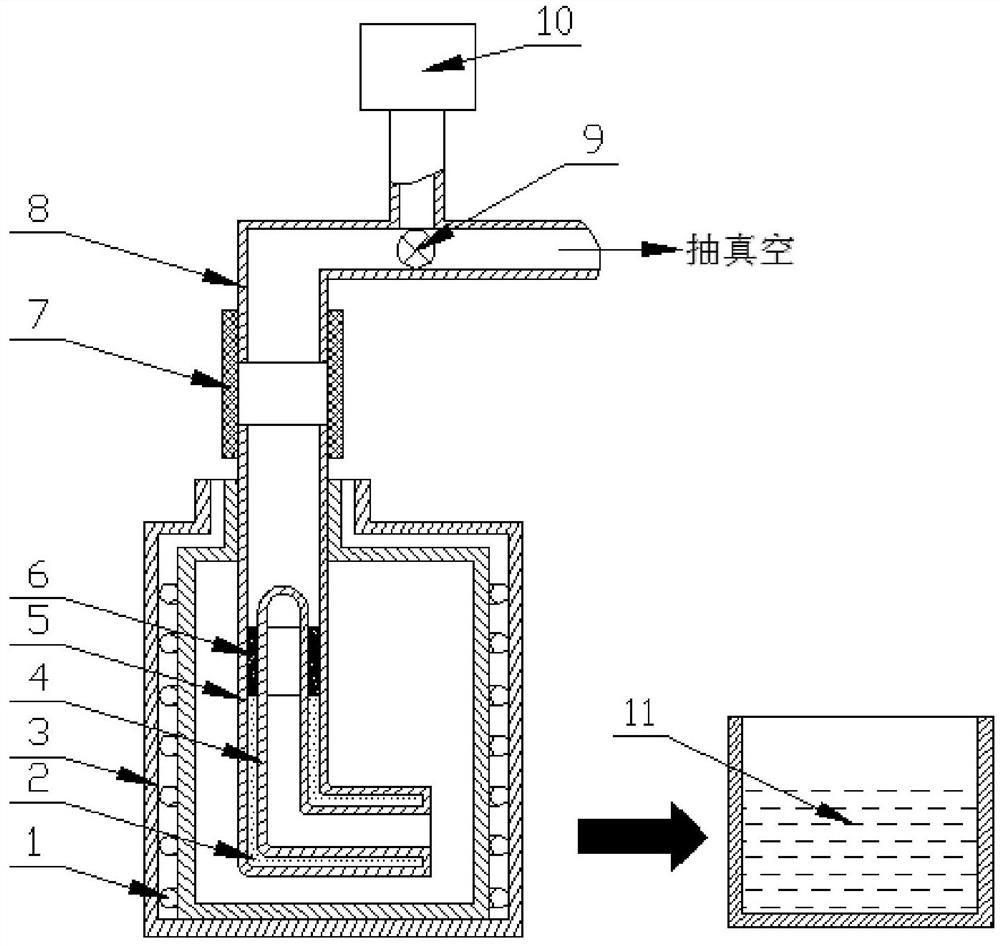

[0039] A mold for preparing an amorphous alloy tube, see Figure 1 to Figure 3 ,include:

[0040] The outer mold quartz tube 5 and the inner mold quartz tube 4 are nested together to form the sandwich cavity, and the inner mold quartz tube 4 has an open edge corresponding to the closed end edge connected to the outer mold quartz tube 5 (that is, the inner mold quartz tube 5). The tube 4 is buckled in the outer mold quartz tube 5, and the opening of the inner mold quartz tube 4 communicates with the outside through the closed end of the outer mold quartz tube 5), and the open end of the outer mold quartz tube 5 extends to the inner mold quartz tube 5. above the closed end of the tube 4 to form a non-nested transition.

[0041] The sandwich cavity can be formed into a straight tube shape by nesting the outer mold quartz tube and the inner mold quartz tube according to the needs (such as figure 1 ), U-s...

Embodiment 2

[0046] Example 2: Preparation of Fe-based amorphous alloy tube

[0047] Based on the amorphous alloy tube preparation device described in Example 1 (see figure 1 ) to implement, including the following steps:

[0048] (1) The smelted master alloy Zr 65 Ni 10 Al 7.5 Cu 17.5 Pulverize into granules (particle size ≥ 2mm, depending on the thickness of the interlayer cavity, try to use large particles as long as it can be loaded into the interlayer cavity); take B 2 O 3 Heating at 350°C for 1 hour, then crushing and grinding to a particle size of ≥300 mesh, and then in a dry atmosphere, quickly mix with the master alloy powder in an amount of 1 / 9 of the volume of the master alloy powder.

[0049] (2) The powdery material obtained by mixing in the previous step is loaded into the interlayer cavity of the mold through the open end of the outer mold quartz tube 5;

[0050] (3) Place the mold segment corresponding to the sandwich cavity in the corresponding resistance heating f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com