A device and method for measuring the competitive adsorption of carbon dioxide and alkanes in shale

A carbon dioxide, competitive adsorption technology, used in measurement devices, suspension and porous material analysis, instruments, etc., can solve the problems of low shale permeability, complex device structure, long test time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

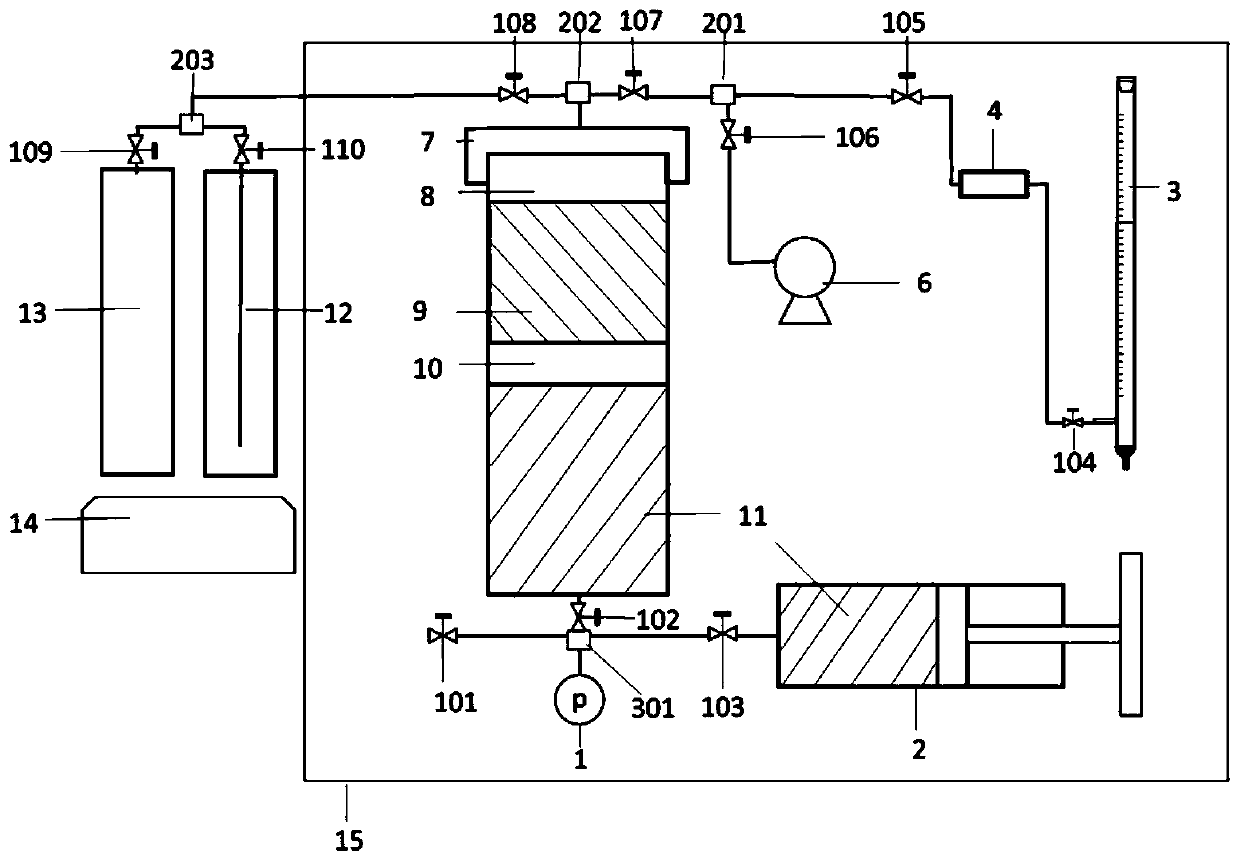

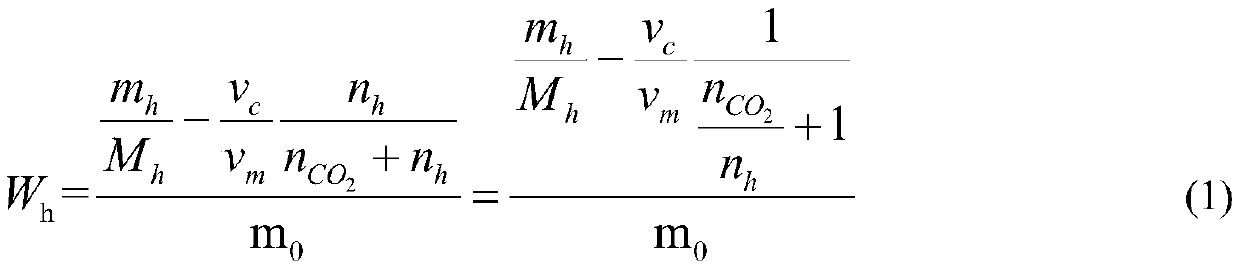

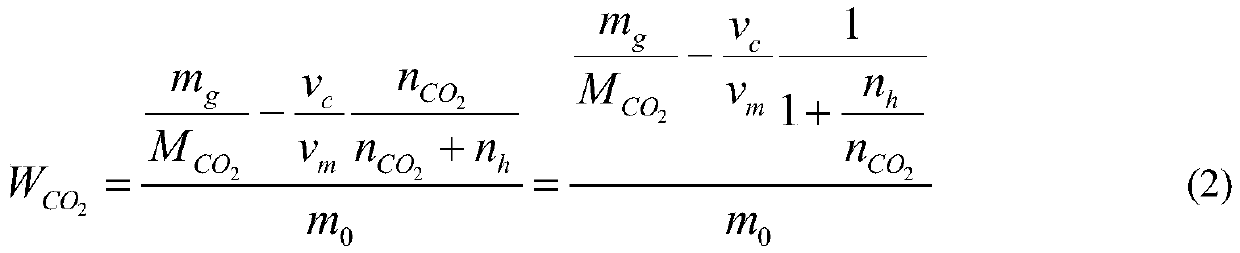

Embodiment 1

[0114] Weigh the skeleton density as ρ=2.5155g / cm 3 of shale particles m 0 =25.00g, the particle size is 200 mesh, put it into volume v 0 =52.8ml reaction vessel 8 tops, by weighing the first three-way joint 201, the 5th shut-off valve 105 and oil-gas separator 4 and its pipeline quality is m 1 =180.326g, and according to figure 1 connection shown. After vacuuming the shale particles, add n-dodecane m to the intermediate container 8 respectively h =9.10g, CO 2 mass m g =0.85g, the pressure of the reaction vessel 8 is controlled by the metering pump 2 to be 8.00MPa. Set the temperature of the temperature control system to 60°C. After the system is adsorbed and balanced, the volumes of the metering pump 2 at the initial moment and the equilibrium moment are respectively v 1 = 0ml, v 2 =26.8ml, through the first three-way joint 201, the fifth shut-off valve 105 and the oil-gas separator 4, the gas-collecting measuring cylinder 3 with the scale and the pipeline with the se...

Embodiment 2

[0116] Weigh the skeleton density as ρ=2.5155g / cm 3 of shale particles m 0 =25.00g, the particle size is 200 mesh, put it into volume v 0 =52.8ml reaction vessel 8 tops, by weighing the first three-way joint 201, the 5th shut-off valve 105 and oil-gas separator 4 and its pipeline quality is m 1 =180.326g, and according to figure 1 connection shown. After vacuuming the shale particles, add n-dodecane m to the intermediate container 8 respectively h =9.27g, CO 2 mass m g =1.86g, the pressure of the reaction vessel 8 is controlled by the metering pump 2 to be 12.00MPa. Set the temperature of the temperature control system to 60°C. After the system is adsorbed and balanced, the volumes of the metering pump 2 at the initial moment and the equilibrium moment are respectively v 1 = 0ml, v 2 =30.6ml, through the first three-way joint 201, the fifth shut-off valve 105 and the oil-gas separator 4, the gas-collecting measuring cylinder 3 with the scale and the pipeline with the s...

Embodiment 3

[0118] Weigh the skeleton density as ρ=3.0408g / cm 3 The 13X type molecular sieve m0=20.00g, the particle diameter is 3.0mm, put it into the volume v 0 =52.8ml reaction vessel 8 tops, by weighing the first three-way joint 201, the 5th shut-off valve 105 and oil-gas separator 4 and its pipeline quality is m 1 =180.326g, and according to figure 1 connection shown. After vacuuming the shale particles, add n-dodecane m to the intermediate container 8 respectively h =20.01g, CO 2 mass m g =1.02g, the pressure of the reaction vessel 8 is controlled by the metering pump 2 to be 8.00MPa. Set the temperature of the temperature control system to 60°C. After the system is adsorbed and balanced, the volumes of the metering pump 2 at the initial moment and the equilibrium moment are respectively v 1 = 0ml, v 2 =18.38ml, through the first three-way joint 201, the fifth shut-off valve 105 and the oil-gas separator 4, the gas-collecting measuring cylinder 3 with the scale and the pipeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com