A head-exchangeable rotary cutter

A rotary tool and interchangeable technology, which is applied in milling cutters, manufacturing tools, metal processing equipment, etc., can solve problems such as reduced connection strength, reduced tool thread interface strength, safe processing, and impact on tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

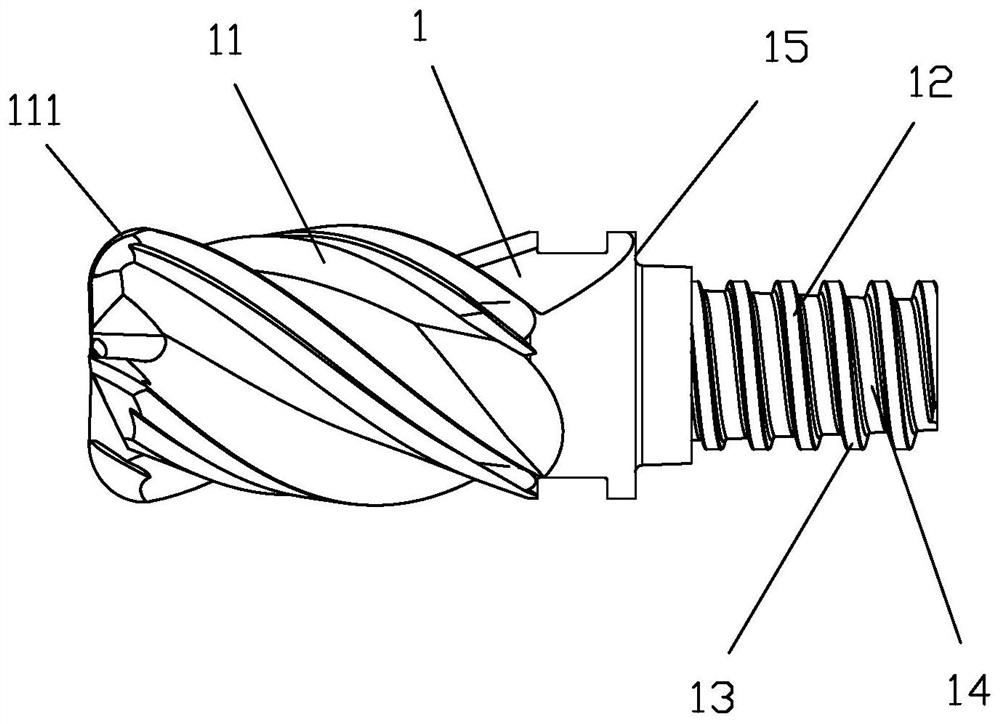

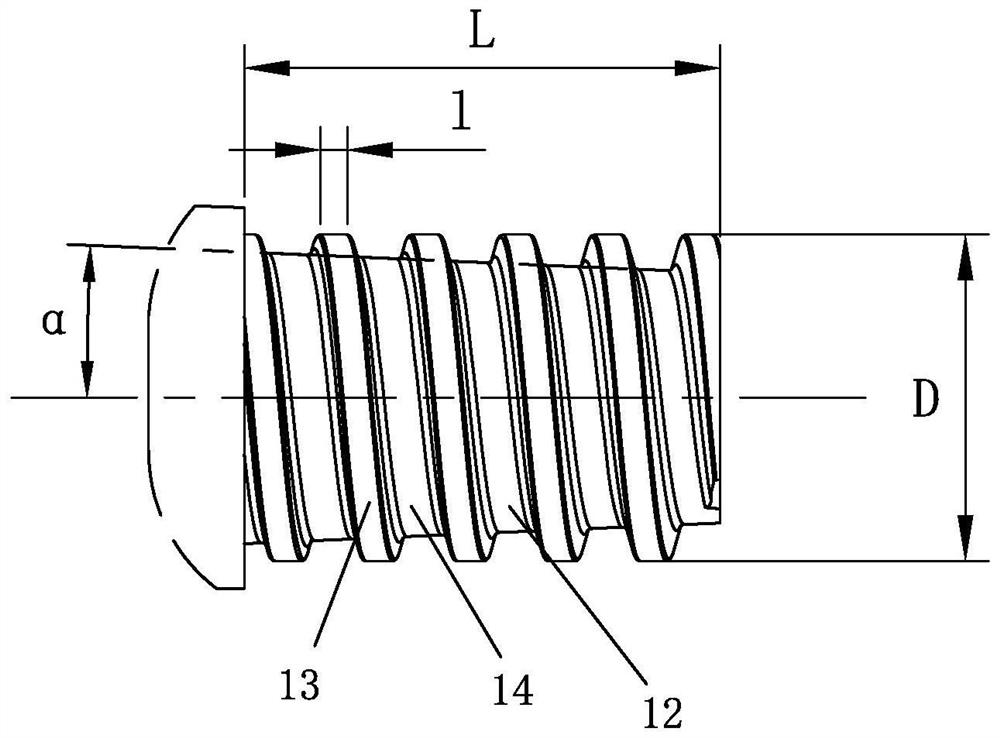

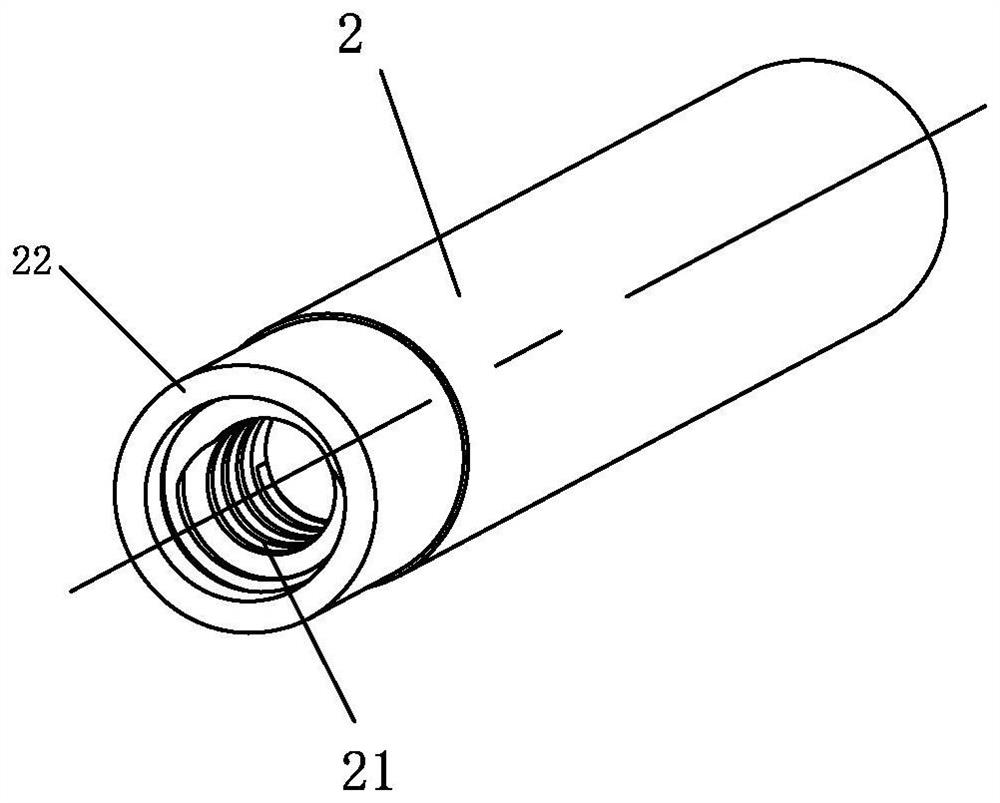

[0032] see Figure 1 to Figure 6 As shown, a head exchangeable rotary cutter of the present invention includes a cutter head part 1 and a tool bar part 2; one end of the cutter head part 1 is provided with a cutting part 11, and the other end is provided with an external thread connection part 12. In this embodiment, the cutting edge 111 of the cutting part 11 is integrated with the cutter head part 1; The threaded connection part 12 fits together. When the cutter head part 1 is matched with the cutter bar part 2, the contact surface 15 of the cutter head part 1 (that is, the protruding end surface at the junction of the cutting part 11 and the external thread connection part 12) and the The contact surface 22 of cutter bar part 2 (being the end face of one end of cutter bar part 2) closely contacts, and its roughness of the contact surface 15 of cutter head part 1 and the contact surface 22 of cutter bar part 2 is no more than 0.8, like this, can Ensure the close contact bet...

Embodiment 2

[0046] see Figure 7 As shown, a head exchangeable rotary cutter of the present invention differs from Embodiment 1 in that the cutter head part 1 is provided with an indexable cutting edge, specifically, the cutter head part 1 passes through The screw 4 is equipped with an indexable insert 3, and the indexable insert 3 has an indexable cutting edge 31 thereon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com