Ballast raking device and long steel rail vehicle set

A component and ballast technology, which is applied in the field of ballast removal device and long rail car group, can solve the problems of low operation efficiency, endangering driving safety, and long time consumption, so as to reduce labor costs, avoid damage to devices, and improve efficiency and safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

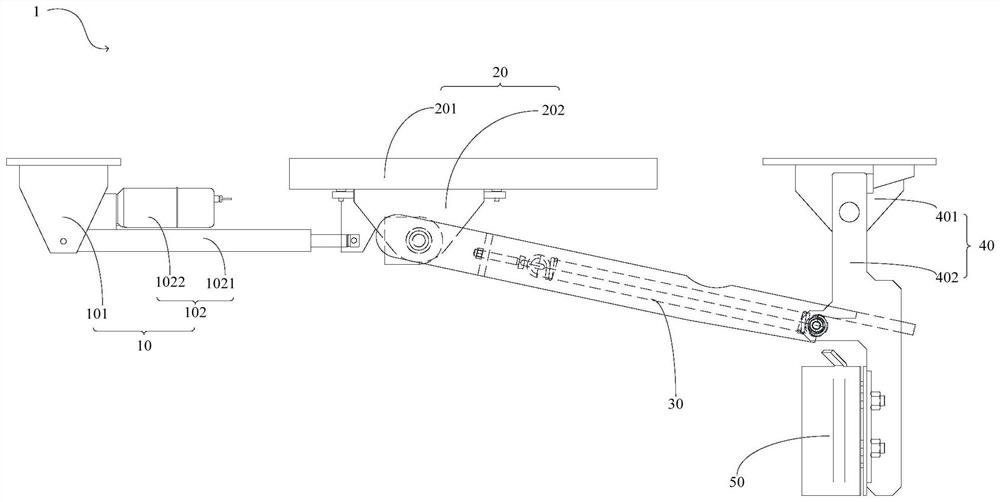

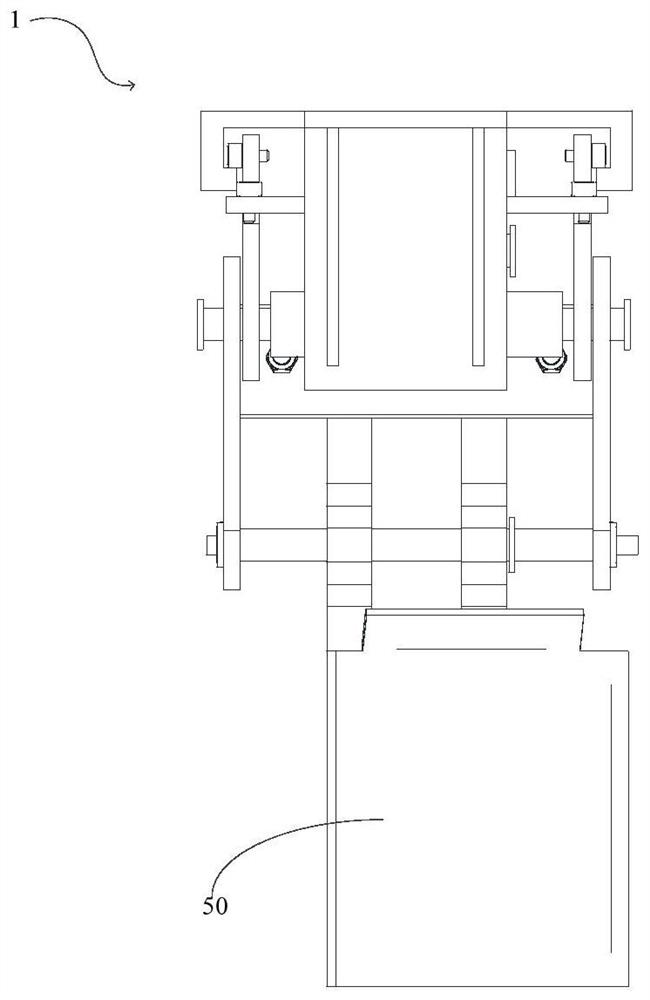

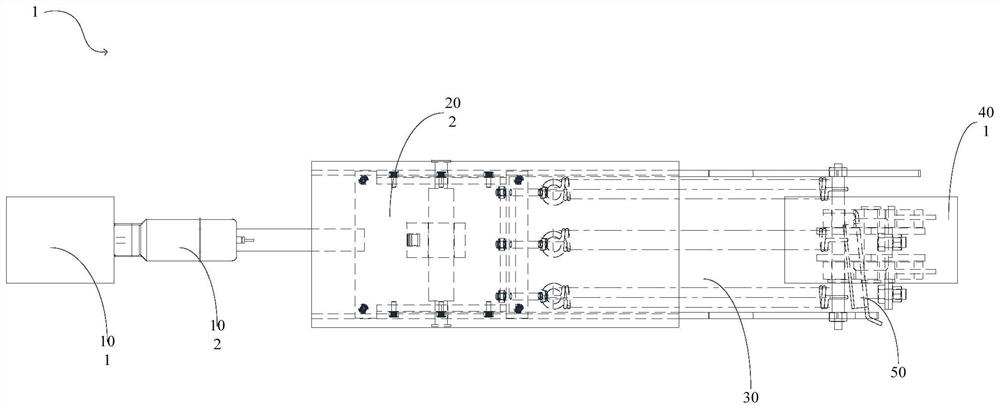

[0123] figure 1 It is a structural schematic diagram of the ballasting device provided in Embodiment 1 of the present invention. figure 2 It is the left side view of the ballasting device provided by Embodiment 1 of the present invention. image 3 It is a top view of the ballasting device provided in Embodiment 1 of the present invention. Figure 4 It is a front view of the push rod seat of the push rod assembly of the ballast removal device provided in Embodiment 1 of the present invention. Figure 5 It is a left view of the push rod seat of the push rod assembly of the ballast removal device provided in Embodiment 1 of the present invention. Figure 6 It is a structural schematic diagram of the moving assembly of the ballasting device provided in Embodiment 1 of the present invention. Figure 7 It is a front view of the chute of the support platform of the moving assembly of the ballasting device provided in Embodiment 1 of the present invention. Figure 8 It is a left ...

Embodiment 2

[0158] Figure 26 It is a schematic structural diagram of the long rail car set provided by Embodiment 2 of the present invention.

[0159] On the basis of the first embodiment above, the second embodiment of the present invention also provides a long rail car set 100, such as Figure 26 As shown, the long rail car set 100 includes a vehicle body 2 and the ballasting device 1 in the first embodiment above.

[0160] Wherein, both sides of the vehicle body 2 are respectively provided with a ballast removal device 1, and the ballast removal device 1 is fixedly connected to the side beams 21 on both sides of the vehicle body 2, specifically, the push rod seat 101, the support platform 201, the pivot arm The seat 401 is welded and fixed on the side beam 21 . Two ballast removal devices 1 are arranged symmetrically along the centerline of the vehicle body 2, and simultaneously level the ballast on the outer sides of the tracks on both sides.

[0161] It should be noted that a loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com