Steel structure suspended ceiling reverse supporting structure

A supporting structure and steel structure technology, applied in the direction of ceiling, building components, building structure, etc., can solve the problems of increasing roof load, reducing the overall reliability of steel structure, increasing load, etc., to eliminate safety hazards, and the assembly method is simple and fast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In view of the fact that the existing steel structure has a large load, difficult construction, and many safety hazards in setting the suspended ceiling, this embodiment proposes a support structure suitable for the construction of the steel structure suspended ceiling, which can quickly and conveniently install the suspended ceiling components into the steel structure.

[0030] Specifically, the technical solution adopted in this embodiment is as follows:

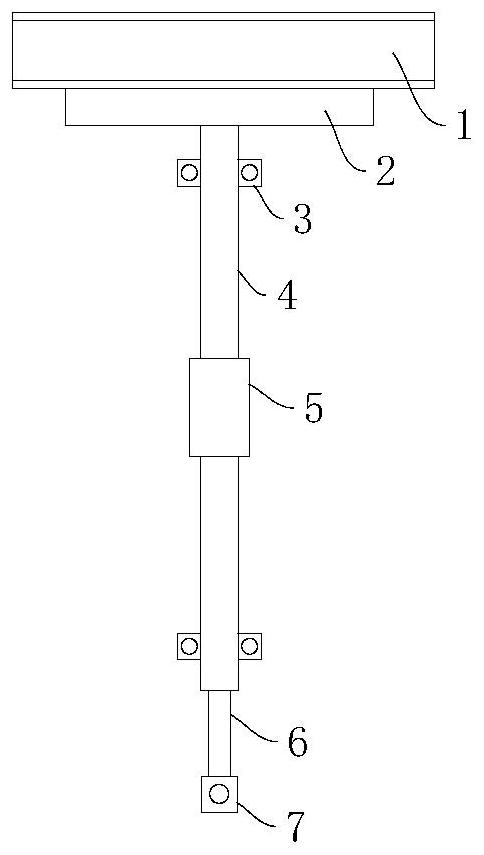

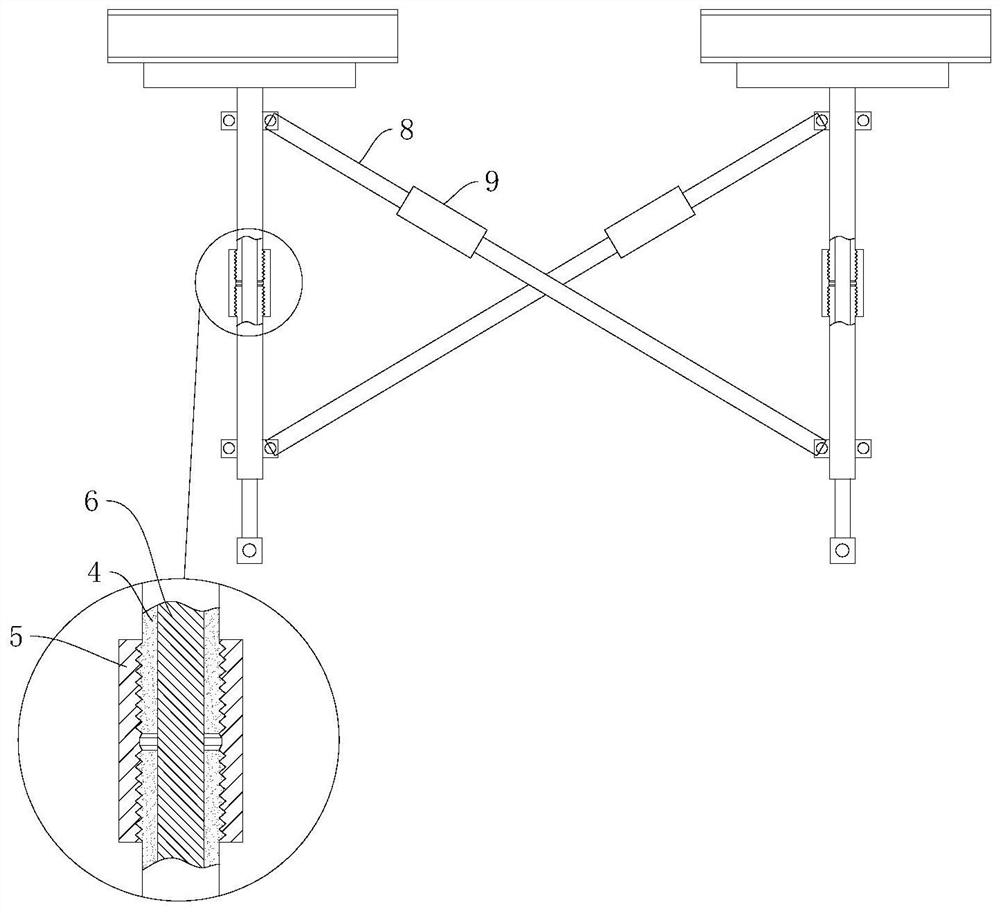

[0031] Such as figure 1 , figure 2 As shown, a steel structure suspended ceiling reverse support structure includes several support units, and the adjacent support units are connected by tensioning and fixing structures; the support units include embedded plates 2 connected with steel structure beams 1, and The lower surface of the buried plate 2 is vertically provided with hanging ribs 6 for connecting and setting the ceiling assembly. The hanging ribs 6 are provided with several sections of sleeves 4, and a usef...

Embodiment 2

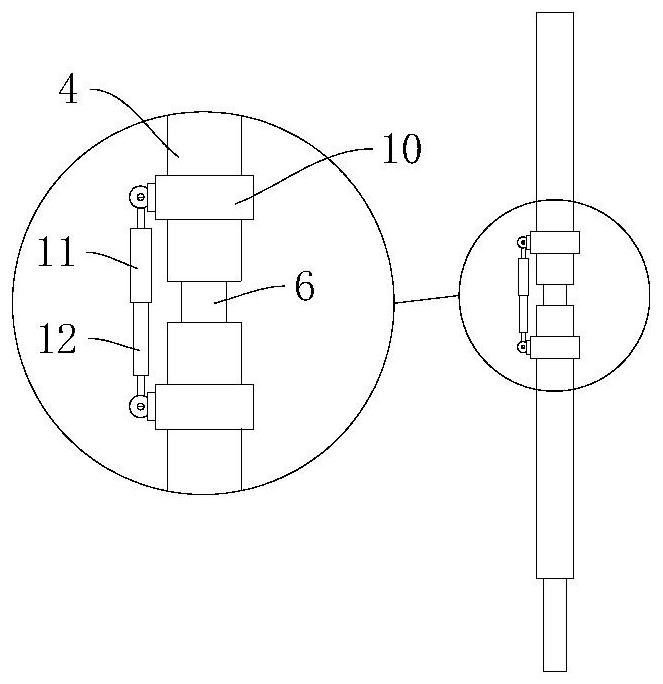

[0045] This embodiment is optimized on the basis of embodiment 1, and discloses a steel structure suspended ceiling reverse support structure. The difference from embodiment 1 is that this embodiment optimizes the structure of the first adjusting member.

[0046] Specifically, such as image 3 As shown, in this embodiment, the end of the sleeve 4 is provided with a connecting portion 10, and the first adjusting part 5 includes a female part 11 and a sub-part 12 connected by a threaded structure, and the female part 11 is connected to the upper end The connecting portion 10 of the sleeve 4 , the sub-section is connected to the connecting portion 10 of the lower end sleeve 4 . When adopting such a scheme, the said parent part 11 and the child part 12 are relatively rotated to adjust the relative distance to realize expansion and contraction. When stretching, the mother part 11 pushes against the sleeve 4 at the upper end, and the child part 12 pushes against the sleeve 4 at the ...

Embodiment 3

[0049] This embodiment is optimized on the basis of embodiment 1, and discloses a steel structure suspended ceiling reverse support structure. The difference from embodiment 1 is that this embodiment optimizes the structure of the second adjusting member.

[0050] Specifically, such as Figure 4 As shown, in this embodiment, the end of the oblique rib casing 8 is provided with a connecting portion 10, and the second adjusting member 9 includes a female member 11 and a child member 12 connected by a threaded structure, the female member 11 and the The connecting portion 10 of the upper end of the oblique rib sleeve 8 is connected, and the sub-component 12 is connected with the connecting portion 10 of the lower end of the oblique rib sleeve 8 . When such a solution is adopted, the parent part 11 and the child part 12 are relatively close to or relatively far away from each other, thereby resisting the corresponding upper end oblique rib sleeve 8 and the lower end oblique rib sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com