Lever-type rapid connection method for flexible pipes

A quick-connect, lever-type technology, applied in the direction of hose connection devices, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as waste, pipe leakage, etc., and achieve the effect of improving efficiency and good installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

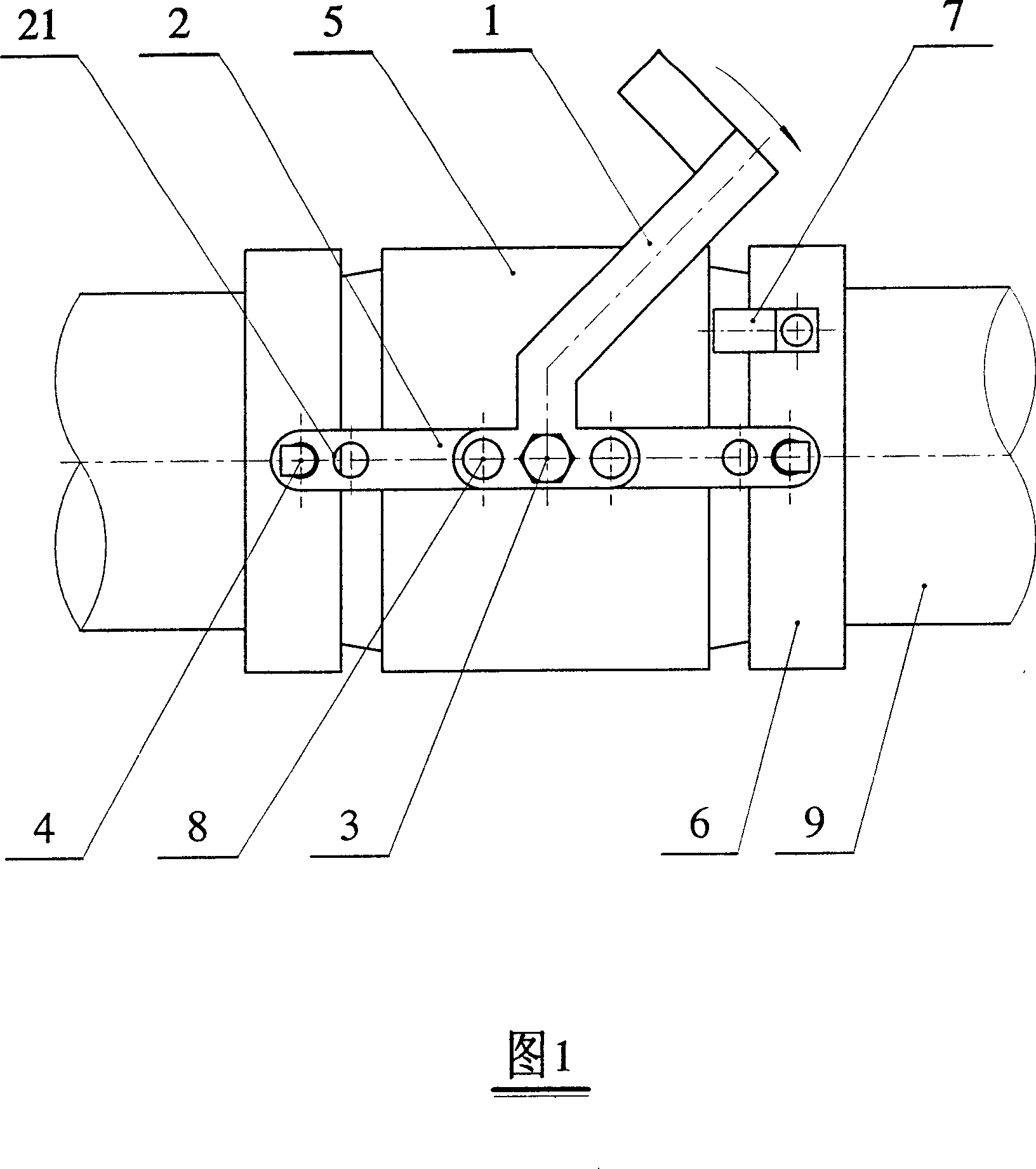

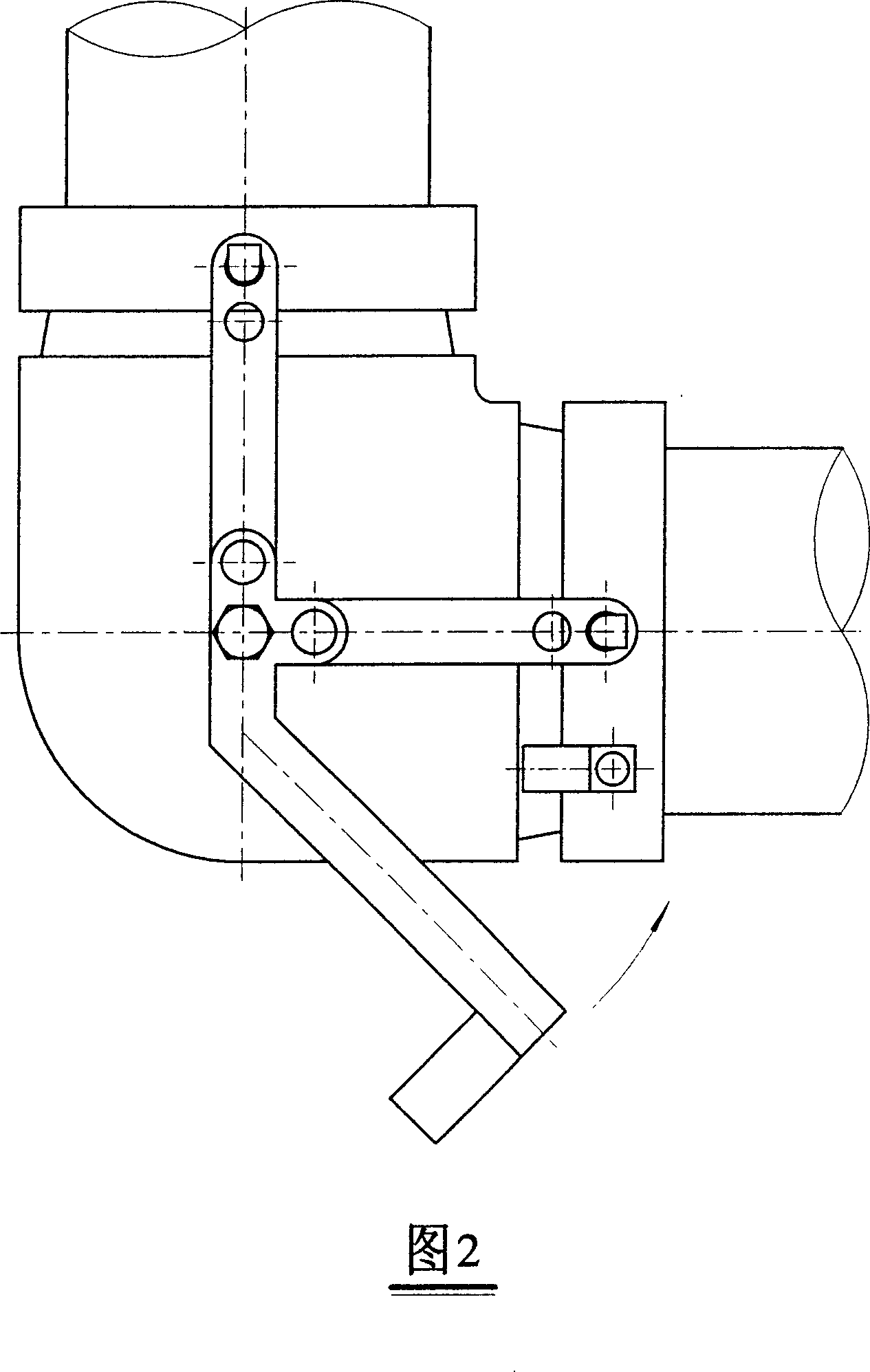

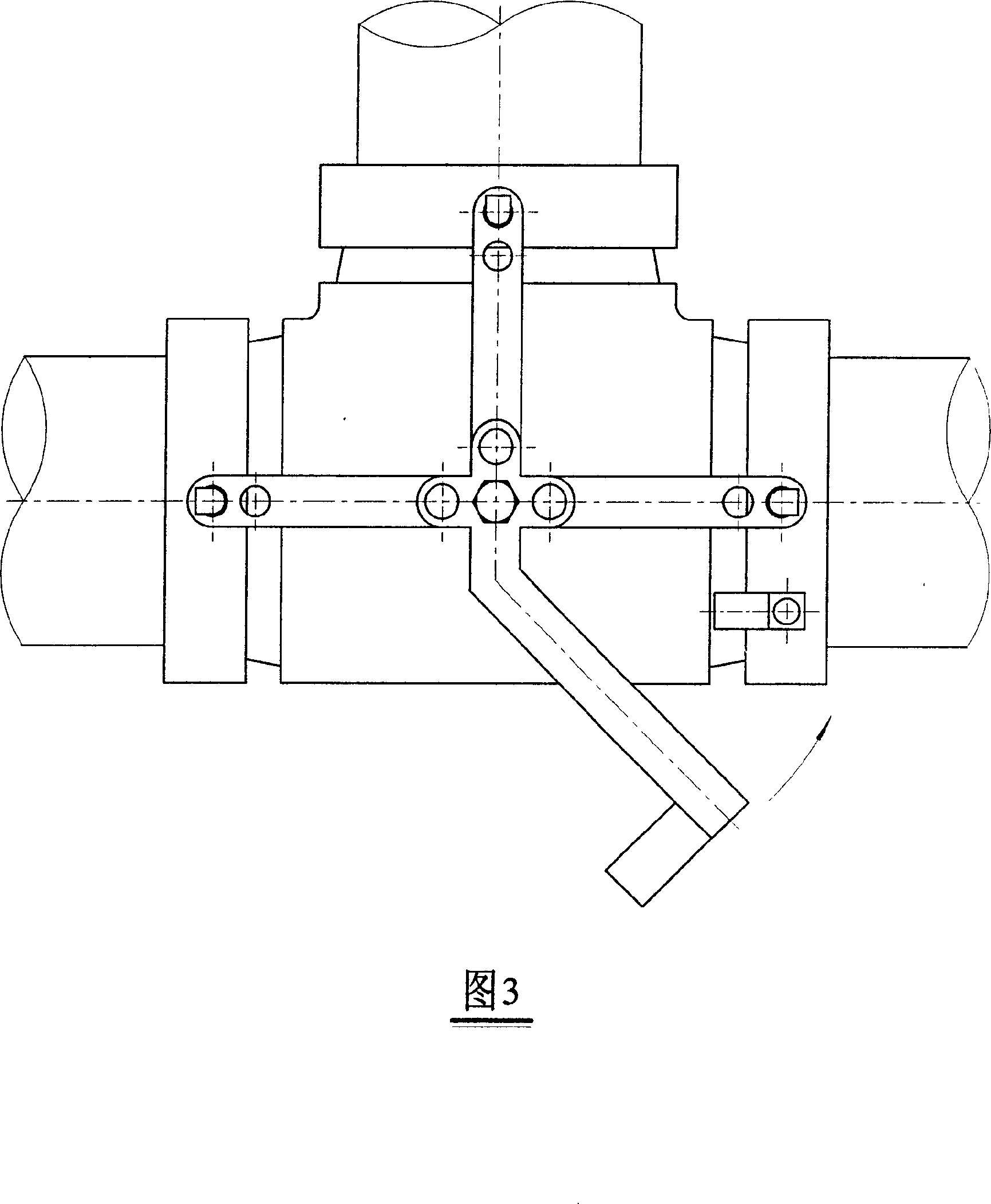

[0035] The structure, features and functions of the lever-type quick connection method for hoses according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0036] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, and Fig. 5, the lever-type quick connection method for hoses of the present invention is a connection structure that realizes fast locking and sealing of pipes through the leverage of crank lever 1 , including crank lever 1, pull rod 2, mandrel 3, tension shaft 4, pipe fitting body 5, hoop 6, positioning card 7, hinge 8, hose 9, said crank lever 1, pull rod 2, mandrel 3. When the product leaves the factory, it has been installed on the pipe fitting main body 5. The crank lever 1 is hinged on the pipe fitting main body 5 with the mandrel screw 3, and the pull rod 2 and the crank lever 1 are hinged together with the rivet 8.

[0037] The tensioning shaft 4 and the positioning card 7 have bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com