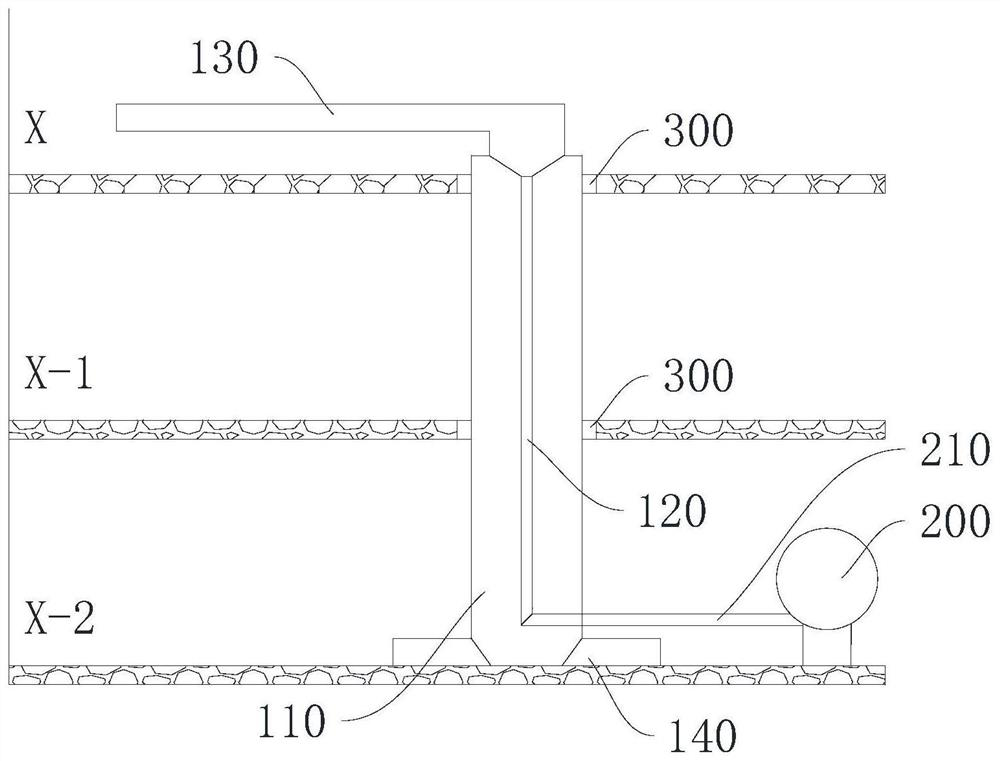

Automatic lifting base for cloth machine

A distributing machine, an automatic technology, applied in the processing of building materials, construction, building construction, etc., can solve the problem of reducing the moving efficiency of the distributing machine, and achieve the effect of eliminating equipment debugging and disassembly and ensuring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

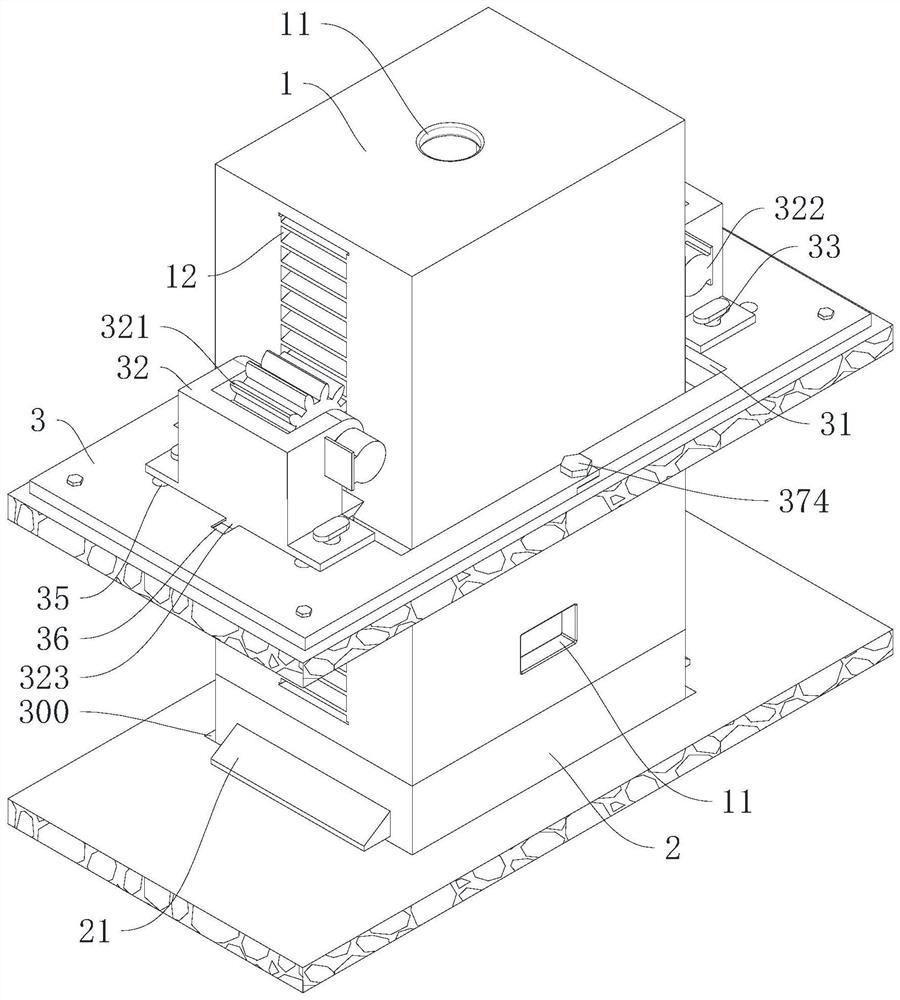

[0092] Please also refer to Figure 8 and Figure 9 , as a specific embodiment of the self-lifting base for a distributing machine provided by the present invention, the meshing component includes a gear 321 and a driving member 322 .

[0093] The gear 321 is rotatably arranged on the sliding member 32 for externally engaging with the tooth slot 12 . The driving member 322 is fixed on the sliding member 32 for driving the gear 321 to rotate. With the movement of the slider 32 in the left-right direction, the gear 321 can move to engage with the tooth slot 12 outside.

[0094] The rotating shaft 324 is connected to the sliding member 32 , the central axis of the rotating shaft 324 is parallel to the front-rear direction, and one end of the rotating shaft 324 penetrates the sliding member 32 and protrudes.

[0095] The gear 321 is connected to the sliding member 32 through the rotating shaft 324 , the central axis of the rotating shaft 324 is parallel to the front-rear direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com