Low-temperature-resistant stainless steel flange and punching machining die thereof

A technology for processing molds and stainless steel, applied in the field of flanges, can solve problems such as unsatisfactory standard flange parts, unfavorable installation, inconvenient adjustment and installation, etc., and achieve the effect of quick installation, favorable installation and convenient adjustment and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

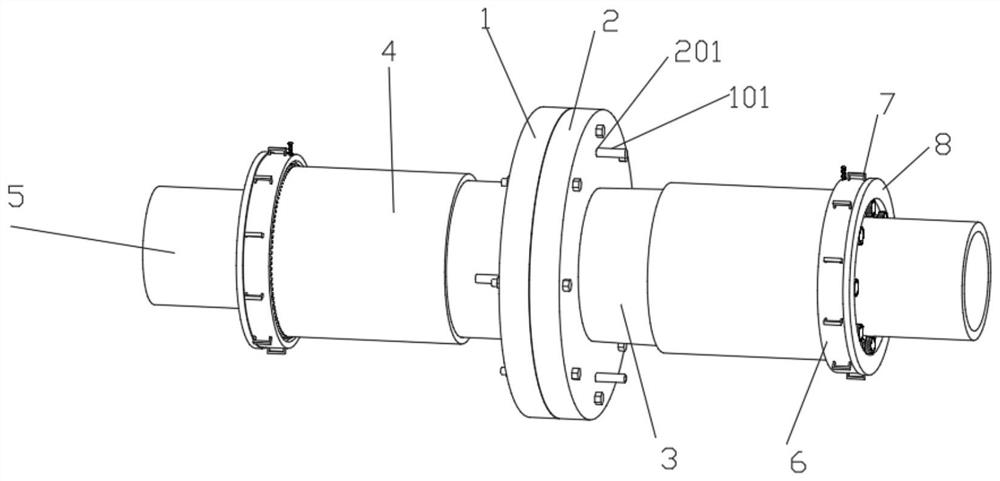

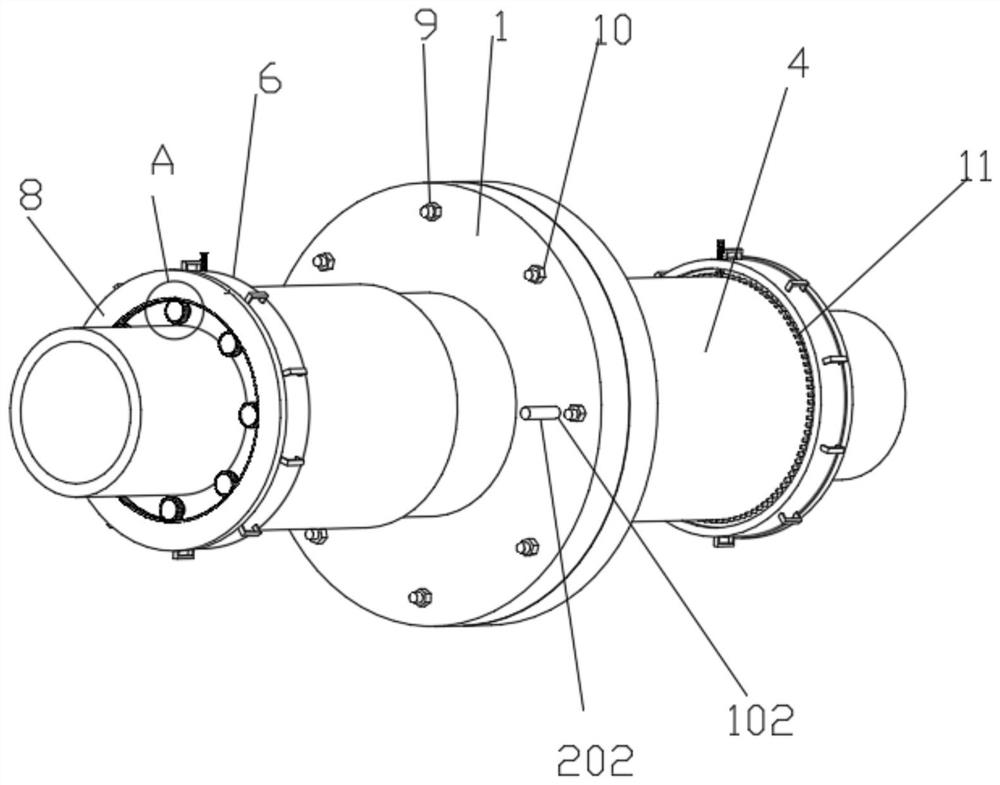

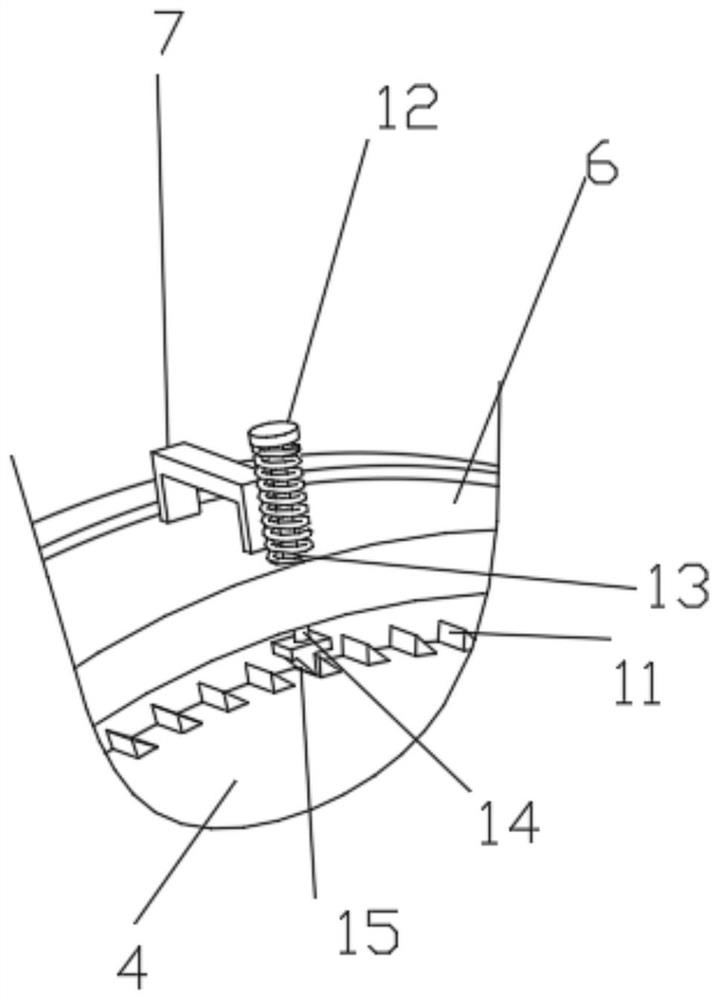

[0038] like Figure 1-5As shown, a low-temperature-resistant stainless steel flange includes a first flange 1 and a second flange 2, the first flange 1 and the second flange 2 are connected with a guide structure, and the guide structure includes a first guide Rod 101, first guide hole 102, second guide hole 201 and second guide rod 202, the first guide rod 101 is symmetrically set on the right side wall of the first flange 1, and the second guide hole 201 is symmetrically set on the second On the side wall of the flange 2, the first guide rod 101 is symmetrically fixed on the right side wall of the first flange 1, and the second guide hole 201 is symmetrically opened on the side wall of the second flange 2, and the first guide The outer wall of the rod 101 is fitted and slidably connected with the inner wall of the second guide hole 201, and the inner wall of the first guide hole 102 is fitted and slidably connected with the outer wall of the second guide rod 202. The length ...

Embodiment 2

[0044] Embodiment 2 is a further improvement to Embodiment 1.

[0045] like Figure 6-8 A punching die for a low-temperature-resistant stainless steel flange is shown, including an upper die 22 and a lower die 25, the upper die 22 is connected to the driving structure, the lower die 25 is fixed and installed, and the bottom of the upper die 22 is formed according to the first flange The mounting hole position of 1 is fixedly connected with a punching rod 24, the mounting hole position of the first flange plate 1 on the top of the lower mold 25 is provided with a punching hole 36, and the top of the lower mold 25 is symmetrically fixedly connected with a third guide rod 30, the first A flange 1 is fitted and slidably connected with the third guide rod 30 through the first guide hole 102, the bottom of the lower mold 25 is fixedly connected with the sleeve 26, and the bottom of the sleeve 26 is fixedly connected with the mounting frame 27, and the mounting frame 27 is fixed Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com