Partial discharge ultrasonic detection device

A detection device and partial discharge technology, which is applied in the field of ultrasonic detection, can solve the problems of increased operation risk, movement deformation, inaccurate test results, etc., and achieve the effect of improving detection accuracy and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

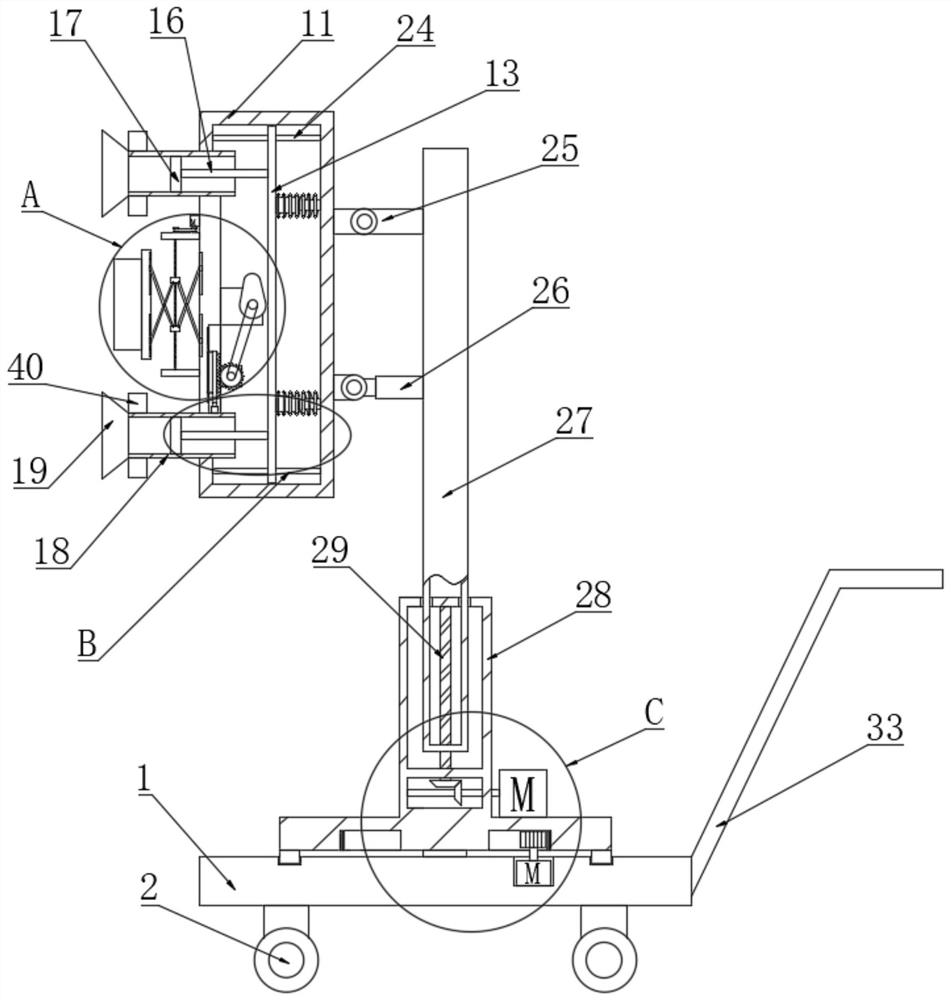

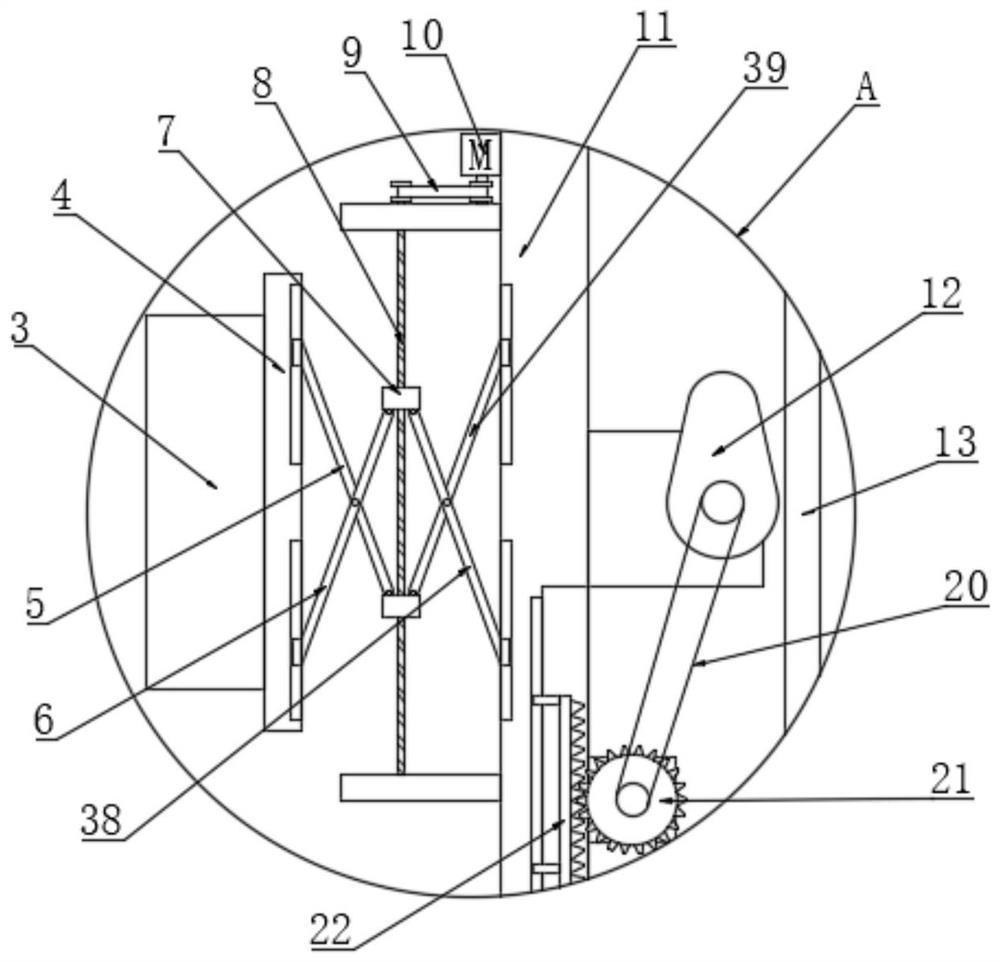

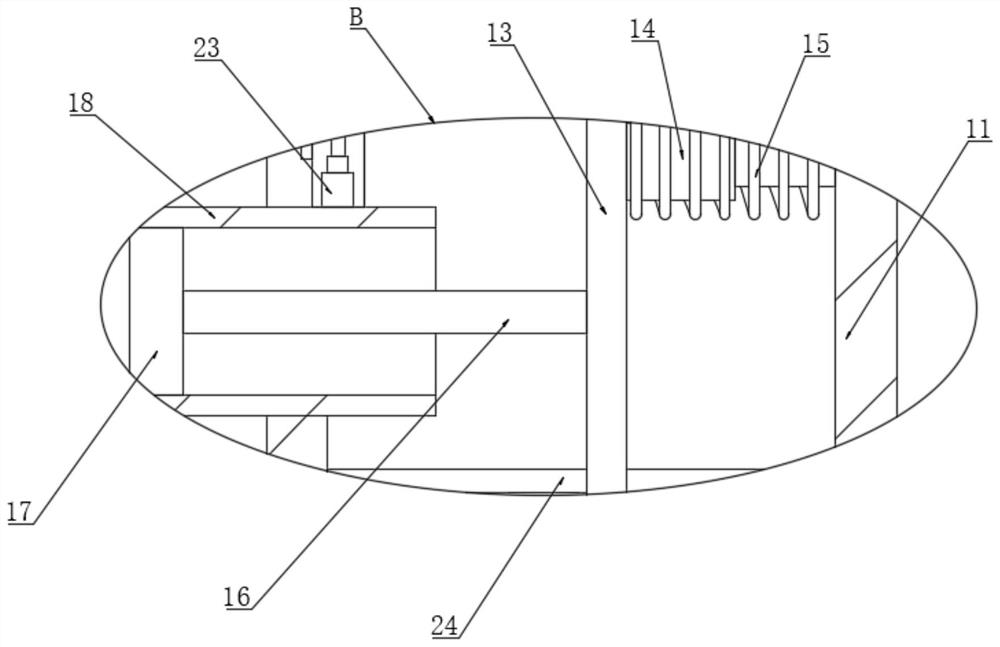

[0028] see Figure 1 to Figure 6 , a partial discharge ultrasonic detection device, including a base 1, the bottom of the base 1 is provided with a universal wheel 2 for easy movement, and the top of the base 1 is provided with an ultrasonic sensor 3 for easy detection, and the ultrasonic sensor 3 passes The support plate 4 is connected with a linear drive assembly, and the linear drive assembly includes a first connecting rod 5, a second connecting rod 6, a connecting seat 7, a first screw 8, a third connecting rod 38, a fourth connecting rod 39 and a first The motor 10, the first connecting rod 5 and the second connecting rod 6 are rotatably connected by a rotating shaft, the third connecting rod 38 and the fourth connecting rod 39 are rotatably connected by a rotating shaft, and the connecting seat 7 is threadedly connected to the first screw rod 8, the first screw 8 is connected to the output shaft of the first motor 10 through the first synchronous belt 9. The outer side ...

Embodiment 2

[0038] see Figure 1 to Figure 6 , a partial discharge ultrasonic detection device, including a base 1, the bottom of the base 1 is provided with universal wheels 2 for easy movement, the top of the base 1 is provided with an ultrasonic sensor 3 for easy detection, and also includes a connection box 11, The connection box 11 is hinged on the lifting column 27 through the hinged seat 25, the cylinder 26 for pitch adjustment is arranged below the hinged seat 25, the lifting column 27 is slidably connected to the lifting base 28, and the lifting column 27 The connection with the lifting base 28 is provided with a lifting drive assembly, and the lifting drive assembly includes a second screw rod 29, a first bevel gear 30, a second bevel gear 31 and a second motor 32, and the lifting column 27 is screwed On the second screw rod 29, the lifting base 28 is rotatably connected to the base 1 through the connecting shaft 37 and the slider. The drive assembly includes a second gear 35 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap