Multi-wire winding method and winding machine

A wire winding and wire feeding technology, applied in the field of multi-wire winding methods and wire winding machines, can solve the problems of dislocation, partial overlap, dislocation of the previous wire and the latter wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

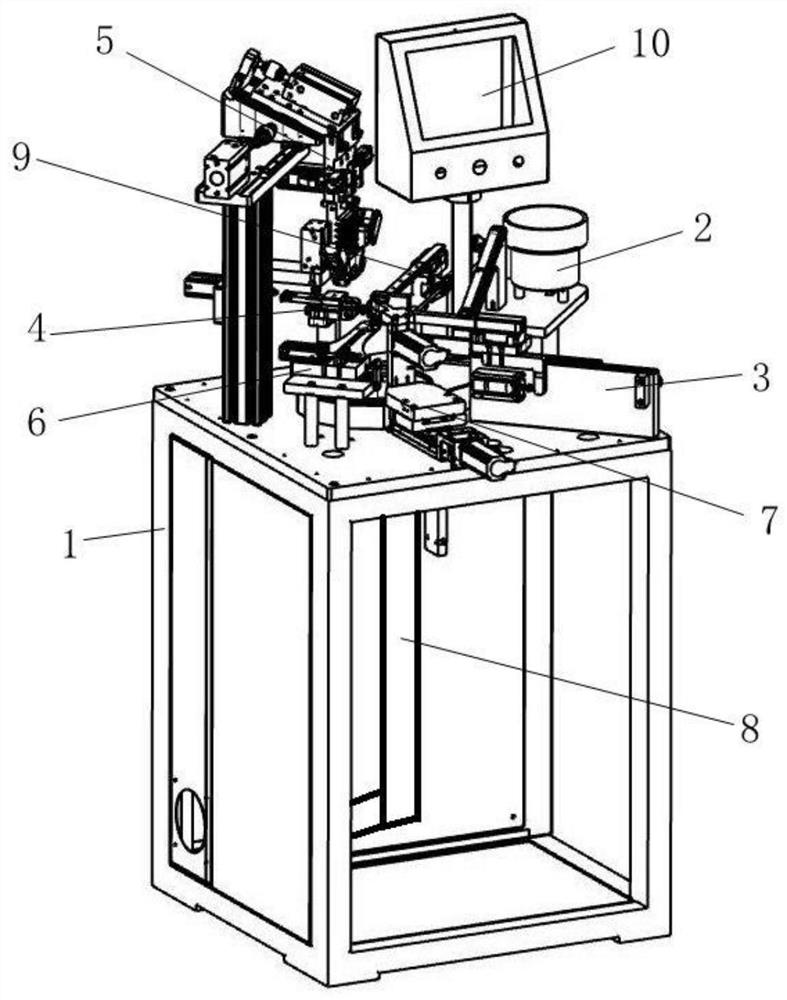

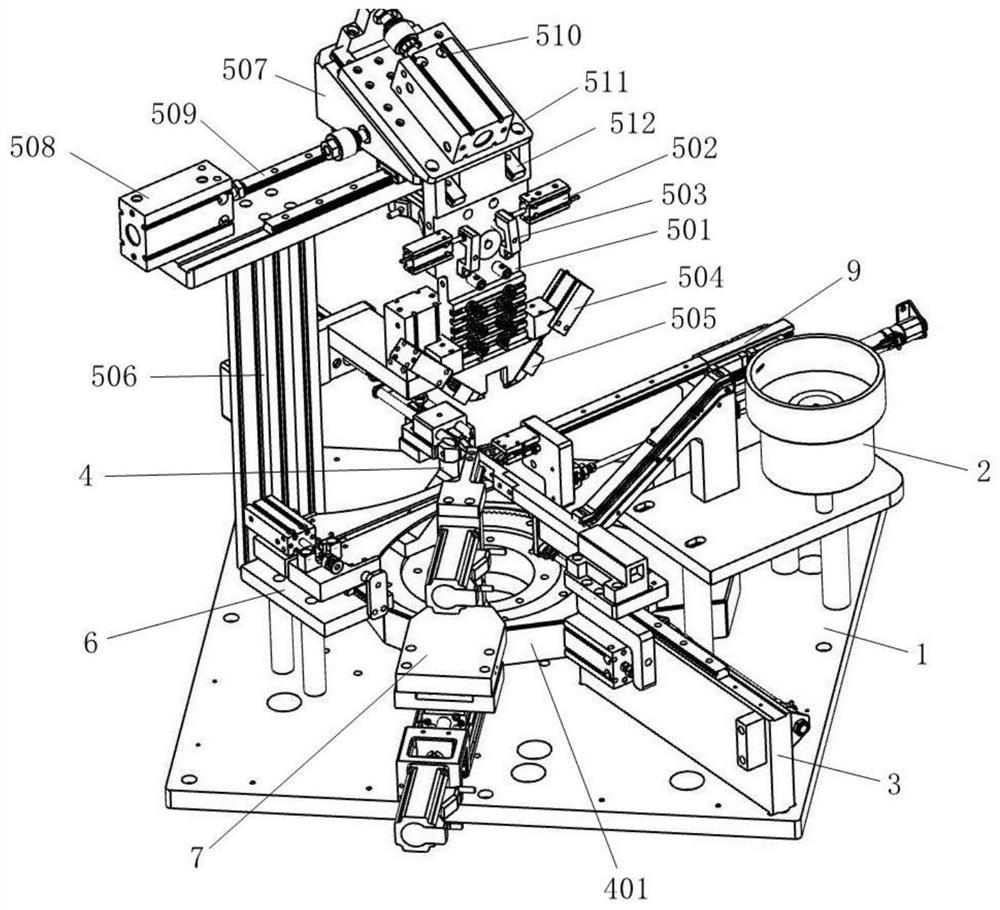

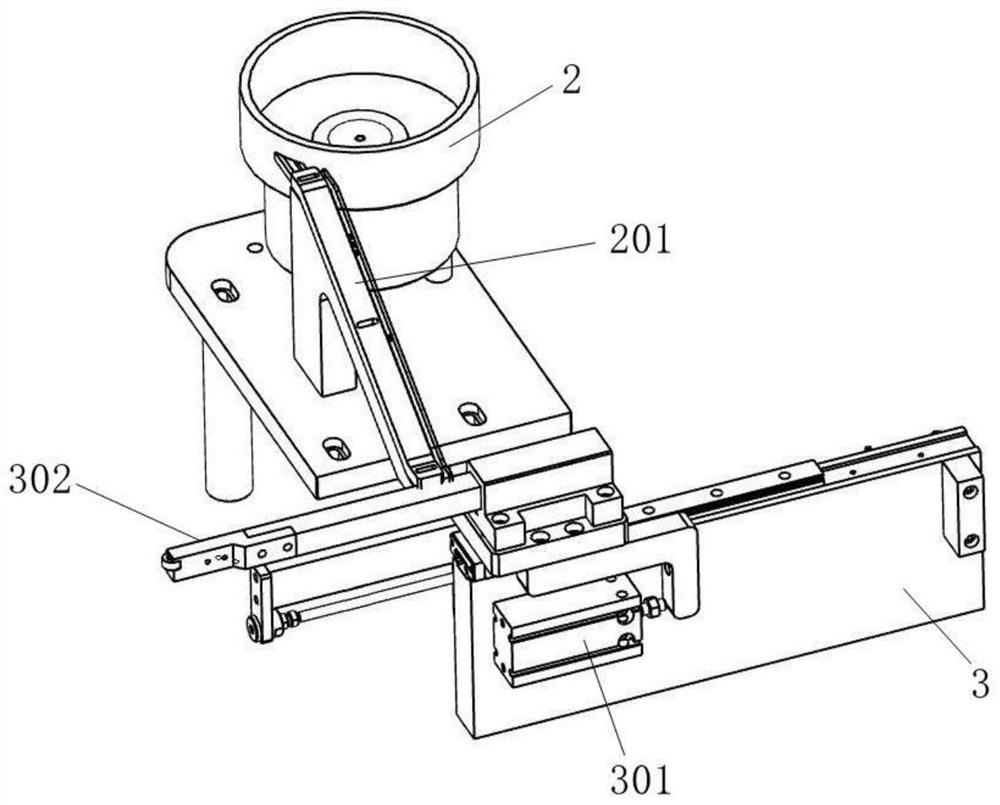

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0045] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

[0046] The invention provides a multi-wire winding method, in which at least two wires are wound on the same iron core, the specific steps are as follows,

[0047] The feeding module transports the iron core 11 to be wound to the clamping station of the iron core 11, and the wire feeding module 5 first transports the previous wire to the clamping station. At this time, the clamping station is in the winding position. The starting point of the previous line, the head end of the previous line passes through the iron core 11, and then the tail end of the previous line is pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com