Apparatus for removing particles using symmetrical gas injection

A gas injection and gas nozzle technology, which is applied in the cleaning method using gas flow, dispersing particle filtration, removing smoke and dust, etc., can solve the problems of staff inhalation and pollution, and achieve the effect of smooth collection and recovery, accurate detection and counting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

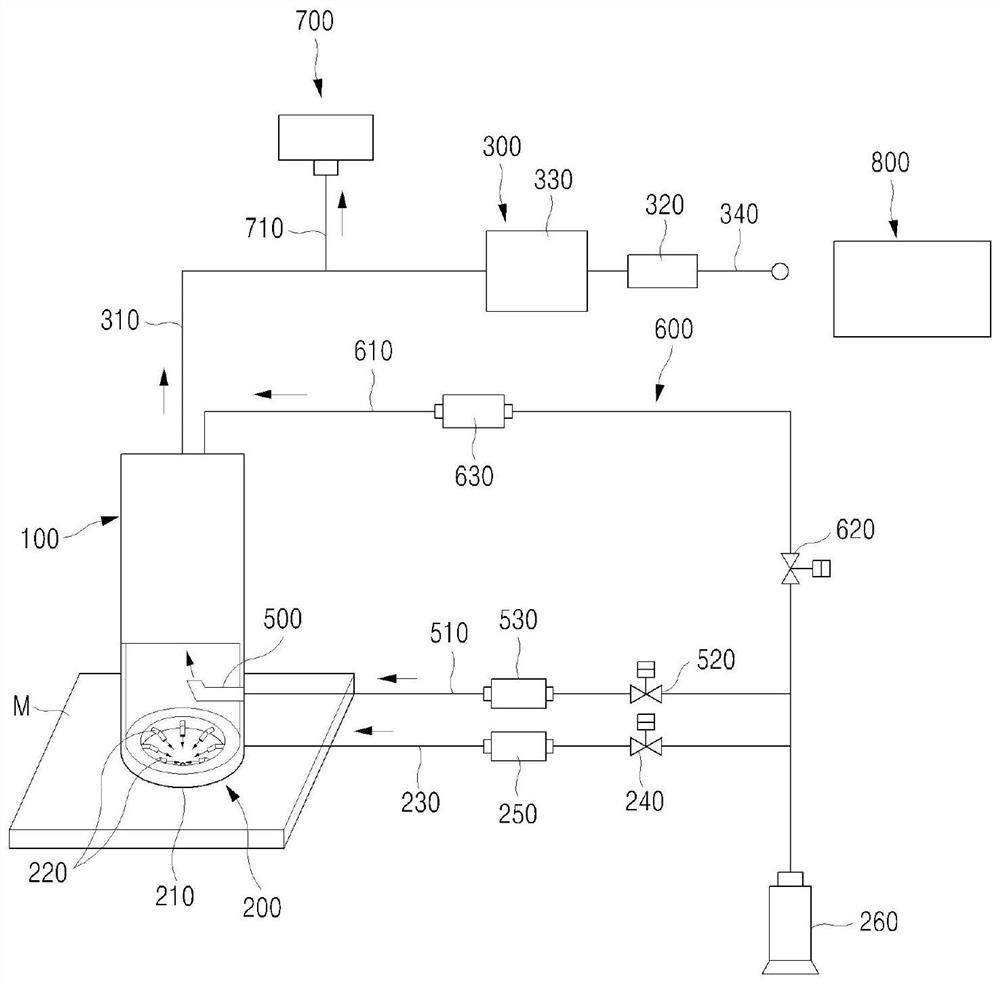

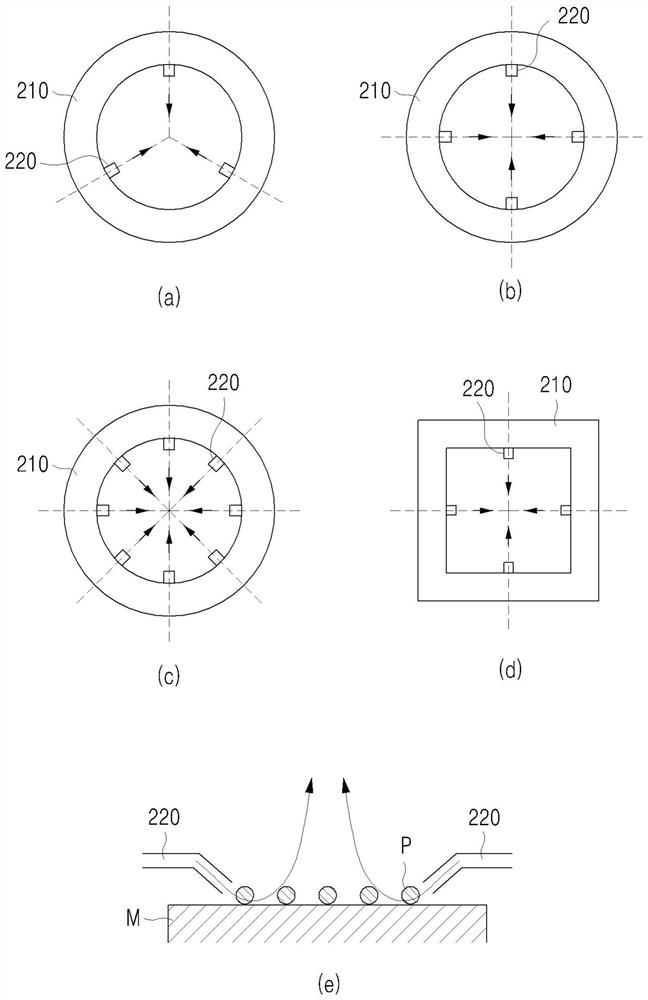

[0022] Hereinafter, specific contents for implementing the particle removal apparatus using symmetrical gas injection according to the present invention will be described in detail centering on examples with reference to the drawings.

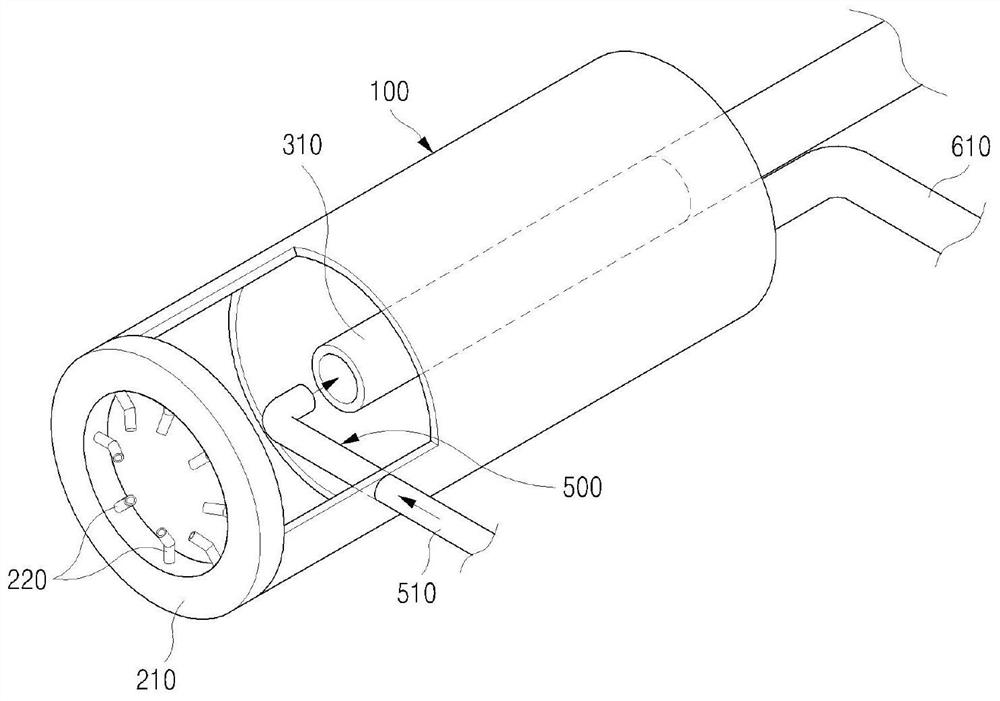

[0023] The particle removal apparatus utilizing symmetrical gas jets according to the present invention is used to efficiently remove particles from the surface of an object for recovery in a clean room or the like, cf. figure 1 , the particle removal device using symmetrical gas injection includes a casing 100, a gas injection part 200, a recovery part 300, and may optionally include a second recovery part 400, a direction guide nozzle 500, a gas injection part 600, a particle detection part 700, The control unit 800 .

[0024] refer to figure 2 , the casing 100 may have an inner space, which is arranged in a vertical or horizontal direction, and provides a space for guiding the particles P separated from the surface of the object to the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com