Rolling brush body, rolling brush, dust collection equipment and forming method of rolling brush body

A technology of rolling brush and forming surface, which is applied to vacuum cleaners, cleaning equipment, suction nozzles, etc., can solve the problems of high energy consumption and large weight of the rolling brush body, and achieve the advantages of avoiding dust accumulation, light weight and reducing radial size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

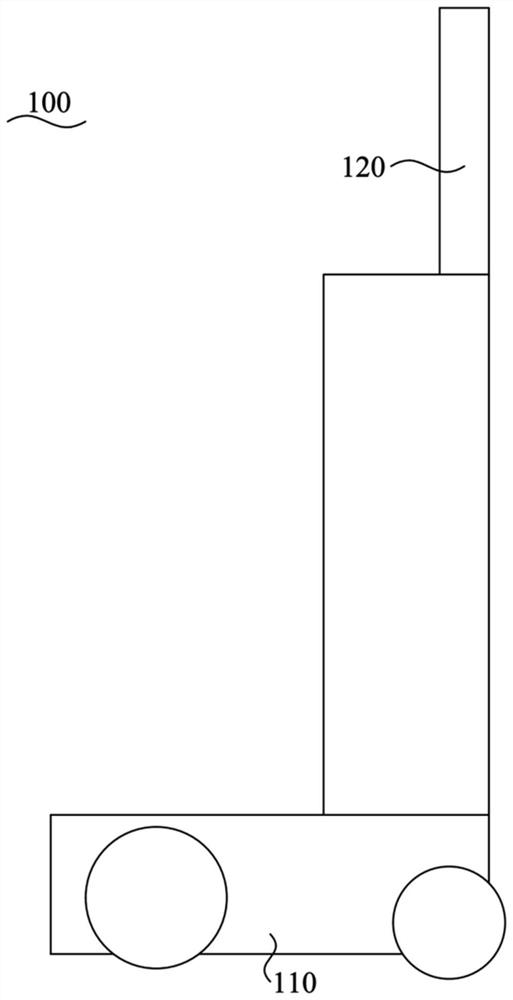

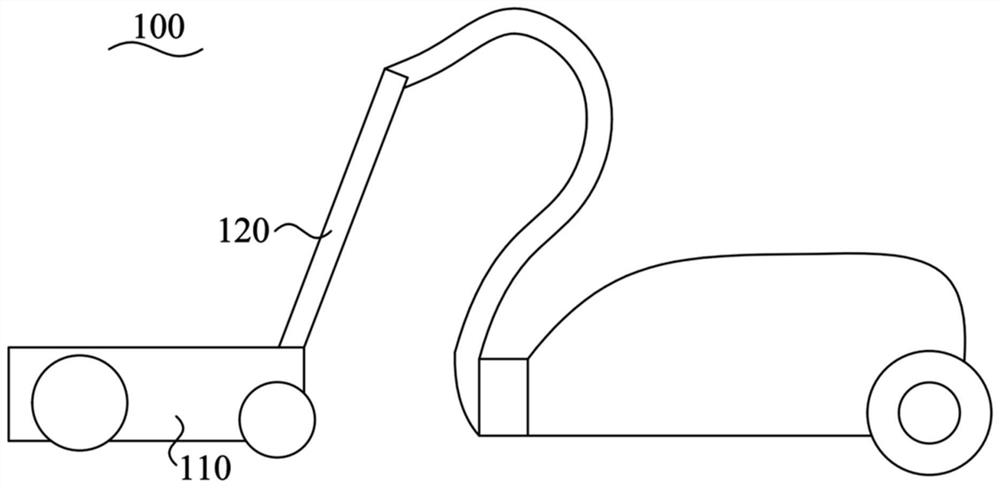

[0082] The present embodiment provides a dust collection device 100. The dust collection device 100 is provided with a dust collection channel and a fan. The dust collection device 100 is provided with a suction inlet, and a rolling brush is installed at the dust suction inlet for rotation. When the fan is working, it can change the air pressure in the dust collection channel, so that the air pressure difference is formed inside and outside the dust collection device 100, and the dust dust outside the dust collection device 100 enters the dust suction channel from the dust suction inlet under the action of the air pressure difference to achieve dust removal. cleaning purposes. During the vacuuming process, the roller brush rotates at the suction inlet, and by patting the surface to be vacuumed, the dust on the surface to be vacuumed can be raised, thereby improving the dust collection effect.

[0083] Optionally, the vacuum cleaner 100 can be a vacuum cleaner or a sweeping rob...

Embodiment 2

[0144] This embodiment provides a dust collection device 100. On the basis of the first embodiment, the rolling brush body 1 is further improved to improve the dust collection effect of the rolling brush body 1 .

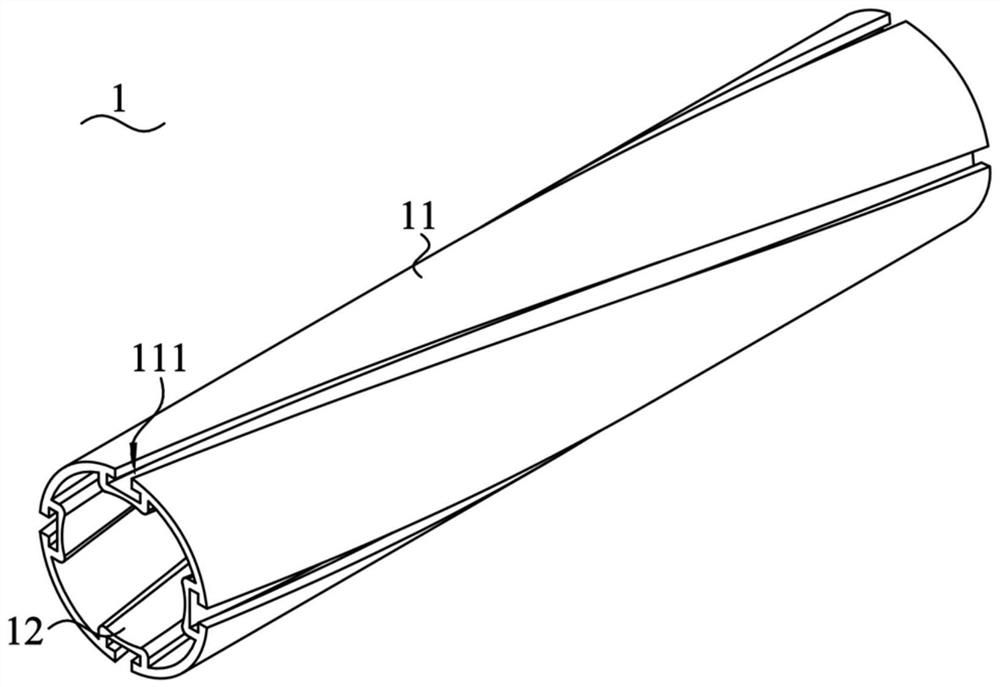

[0145] Specifically, such as Figure 16 As shown, the groove 111 includes a connected first groove segment 1111 and a second groove segment 1112, and the helical parameters of the first groove segment 1111 and the second groove segment 1112 are different, so that the groove 111 as a whole has a variable helical structure, so that according to Use as needed or better for dust removal. Correspondingly, the first rib 12 includes a connected first extension section and a second extension section, the first extension section corresponds to the position of the first groove section 1111 and has the same helical parameters, and the second extension section and the second groove section 1112 The positions are corresponding and the helical parameters are the same, so as to e...

Embodiment 3

[0158] This embodiment provides a method for forming a rolling brush body, which is used for forming the rolling brush body 1 in Embodiment 1 or Embodiment 2, and the method is applied to an injection mold. Specifically, the rolling brush body 1 is formed by injection molding. The injection mold includes an outer core 21 and an inner core 22 that is installed in the outer core 21. When the inner core 22 and the outer core 21 are in the molding position, a molding cavity is formed therebetween, and the roller brush body 1 is molded on the outer core 21. In the molding cavity between the core 21 and the inner core 22. Wherein, the outer core is provided with groove forming ribs 2111 for forming grooves, and the inner core 22 is provided with rib forming grooves for forming the first ribs 12 .

[0159] The molding method provided in this embodiment includes a mold clamping step, an injection molding step and a demoulding step. In the mold clamping step, the inner core 22 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap