Novel air bag type pneumatic mechanical claw

A mechanical claw and airbag technology, applied in the field of new airbag pneumatic mechanical claw, can solve the problems of high-speed application, such as inability, slow grasping speed, complex structure, etc., to achieve low cost of use and maintenance, easy to use and adapt to powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

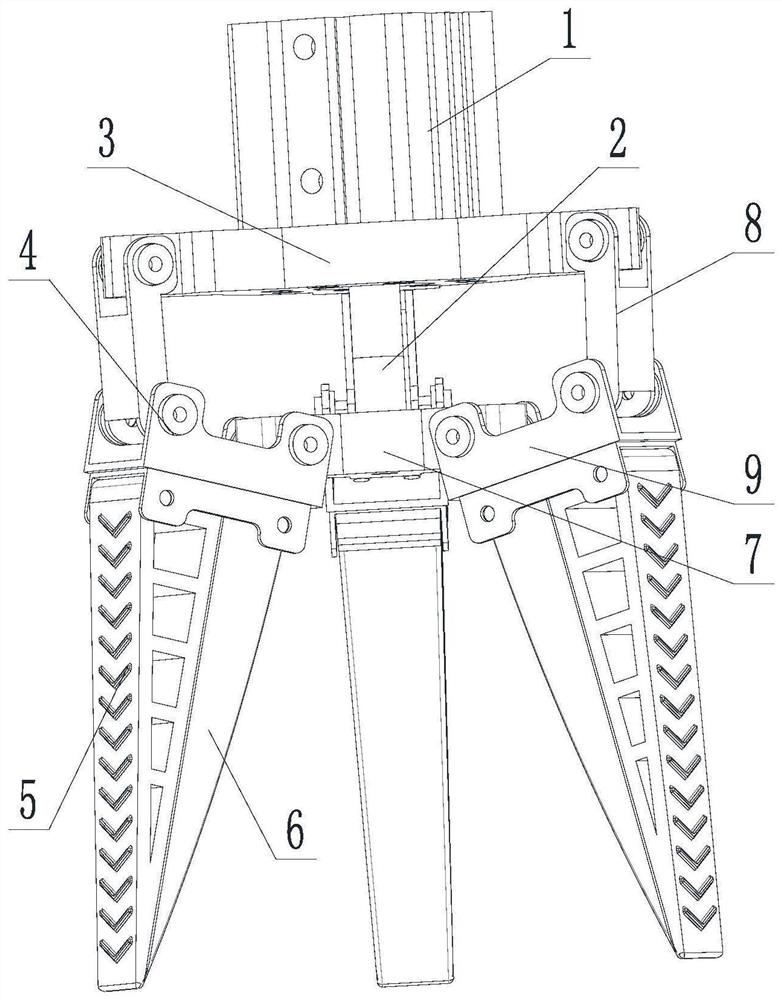

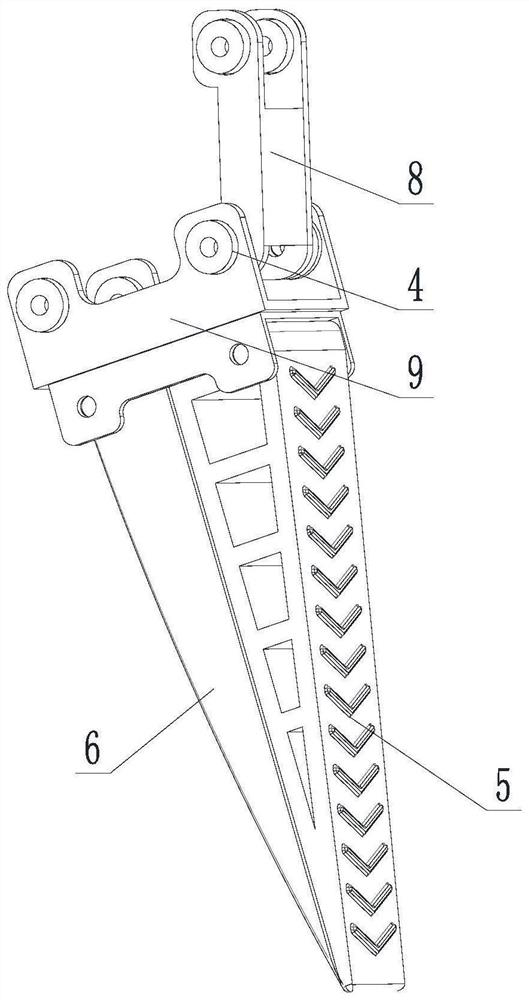

[0021] see Figure 1-2 , a new airbag-type pneumatic mechanical claw, including a fixed platform 3 and a mechanical claw body, the mechanical claw body includes a plurality of flexible grasping fingers 5 that can be deformed and bent, and the fixed platform 3 is fastened to the main cylinder 1 by screws Above, the main cylinder 1 has a built-in piston, and the piston is connected with a linkage shaft 2 whose lower end extends out of the main cylinder 1. The lower end of the linkage shaft 2 runs through the fixed platform 3 and extends below the fixed platform 3, and the end of the linkage shaft 2 is connected with a motion platform 7 , the mechanical claw is located at the bottom of the fixed platform 3, the top of the flexible grabbing finger 5 is provided with a finger fixing seat 9, the outer end of the finger fixing seat 9 is rotationally connected with the finger connector 8 through the bearing 4, and the inner end of the flexible grabbing finger 5 passes through the beari...

Embodiment 2

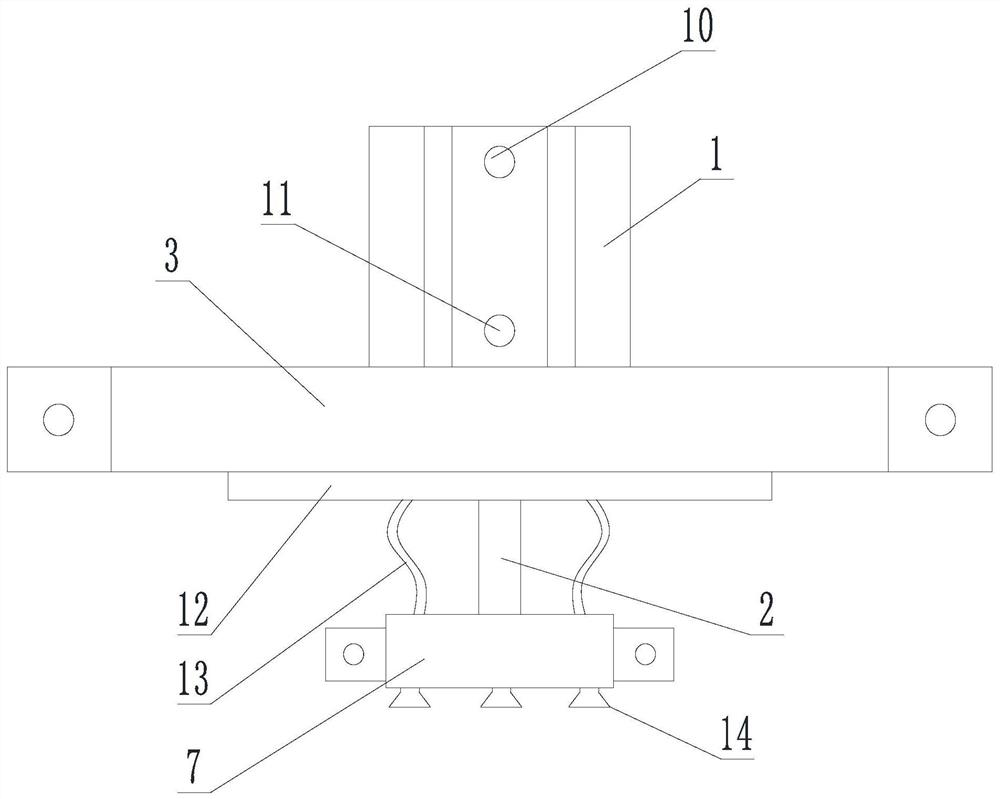

[0027] refer to image 3 , on the basis of Embodiment 1, when actually grabbing, in order to further ensure the stability of grabbing, a plurality of negative pressure suction cups 14 are also provided at the bottom of the moving platform 7, and the negative pressure suction cups 14 are downward openings. Trumpet-shaped, between the moving platform 7 and the fixed platform 3, there are a plurality of negative pressure connecting pipes 13 corresponding to the negative pressure suction cups 14 and sealingly docked, and the upper ends of the negative pressure connecting pipes 13 are sealed and docked with the distribution air pipe 12. The distribution air pipe 12 is attached to the bottom surface of the fixed platform 3. When grabbing large-scale items, the position of the moving platform 7 is firstly controlled by the master cylinder 1, and the expansion of the flexible airbag 6 is adjusted to ensure that the size of the item is consistent with the grab. At the same time, the ne...

Embodiment 3

[0029] refer to Figure 4 On the basis of Embodiment 2, the device also includes a pneumatic control system, the pneumatic control system includes a main controller 15, and the main controller 15 is connected to the main cylinder 1, the air bag valve controller 16 and the negative pressure valve 18, The airbag valve controller 16 is connected with a plurality of airbag valves 17, the number of the airbag valves 17 is the same as that of the flexible airbag 6 and connected one by one, the airbag valve 17 has an exhaust pipe and an intake pipe, and the negative pressure valve 18 Connect the distribution air pipe 12.

[0030] Through the centralized control of the main controller 15 in the pneumatic control system, the inflation and deflation of different structures can be reasonably distributed, and through the setting of multiple independent airbag valves 17 and airbag valve controllers 16, irregular objects When grabbing, the expansion of each flexible airbag 6 can also be in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap