Systems and methods for additive manufacturing of transport structures

一种用户、模型的技术,应用在增材制造领域,能够解决时间、成本、制造复杂、不足等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

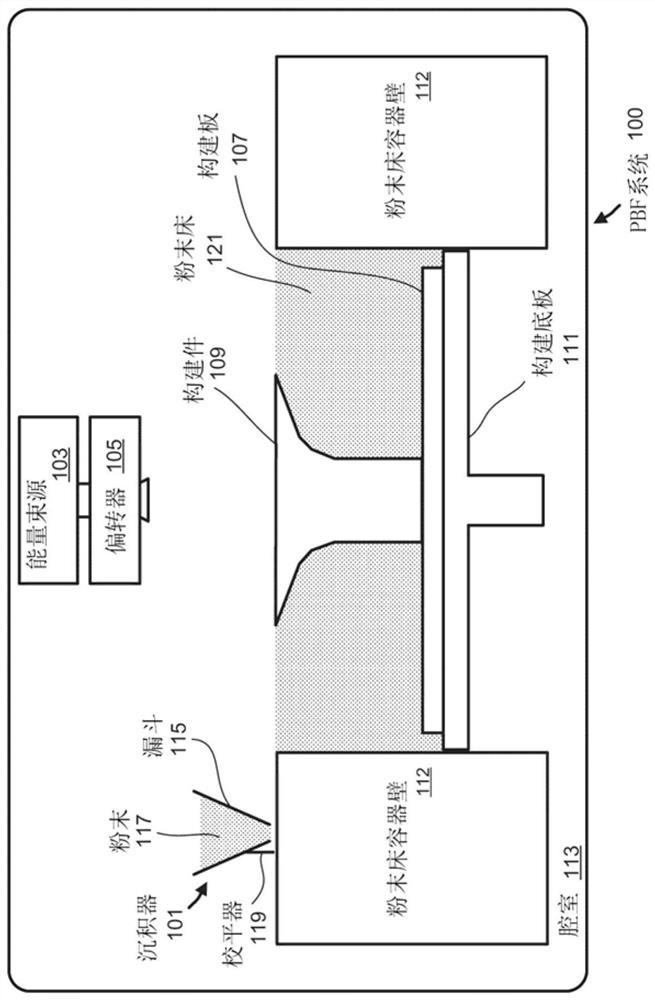

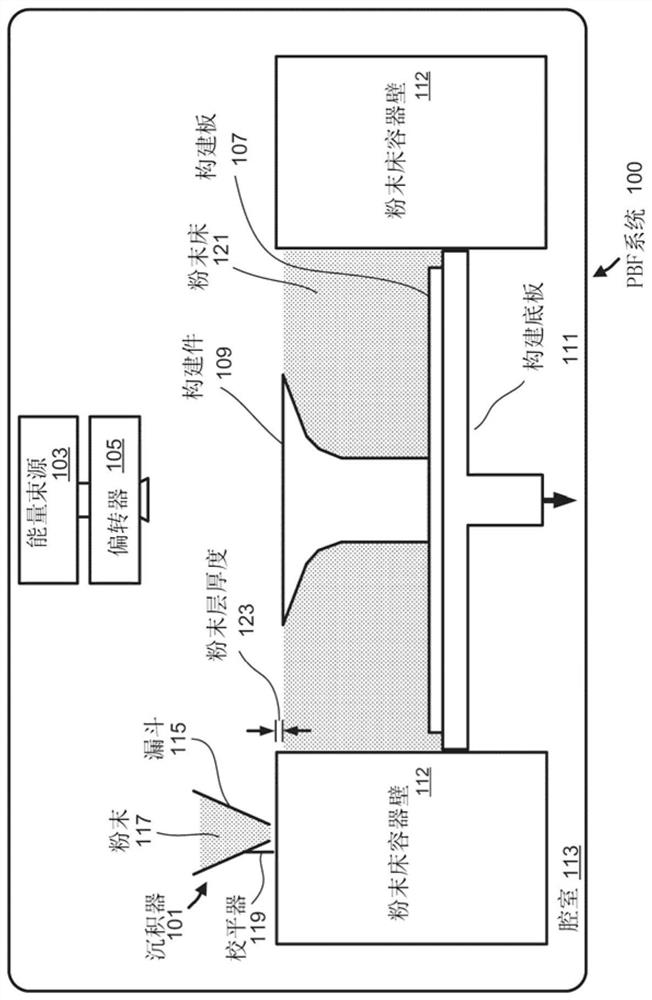

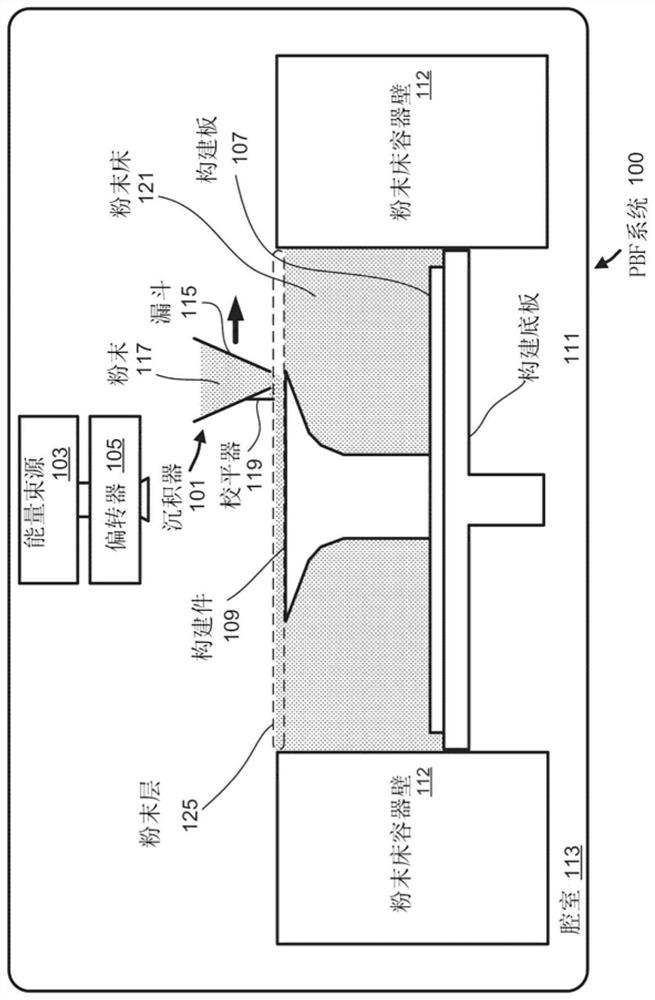

[0033] The detailed description, set forth below in conjunction with the accompanying drawings, is intended to provide a description of various exemplary embodiments of the concepts disclosed herein, and is not intended to represent the only embodiments in which the disclosure may be practiced. The term "exemplary" as used in this disclosure means "serving as an example, instance or illustration" and should not necessarily be construed as preferred or advantageous over other embodiments presented in this disclosure. The detailed description includes specific details for the purpose of providing a thorough and complete disclosure that fully conveys the scope of the concepts to those skilled in the art. However, the disclosure may be practiced without these details. In some instances, well-known structures and components may be shown in block diagram form, or omitted entirely, in order to avoid obscuring the various concepts presented throughout this disclosure.

[0034] 3-D pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com