Short-distance fine-tuning machine base for automobile charging pile

A car charging and short-distance technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problem of charging piles being unable to charge, and achieve the effects of preventing power cord breakage, assisting reset, and ensuring electricity safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

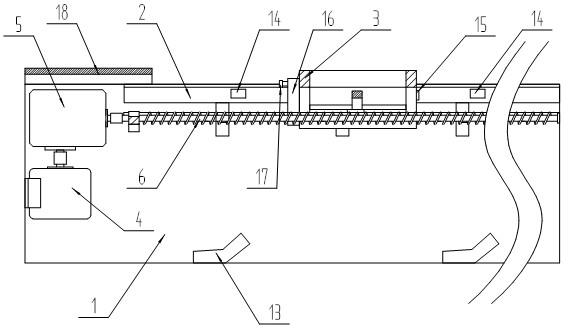

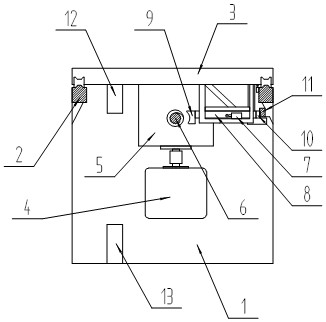

[0020] refer to Figure 1-2 , is a structural schematic diagram of Embodiment 1 of the present invention, a short-distance fine-tuning base for a car charging pile, characterized in that it includes a bottom groove 1, a top frame 2, a carriage 3, a motor 4, a reducer 5, a lead screw 6, Electromagnetic push rod 7, linkage frame 8, drive block 9, brake block 10 and brake rack 11, one end of the bottom groove 1 is detachably connected to the reducer 5, and the motor 4 is detachably connected to one end of the bottom groove 1 , and the drive end of the motor 4 is connected to the input end of the reducer 5, one end of the screw 6 is connected to the reducer 5, the other end of the screw 6 is connected to the inner wall of the bottom groove 1 in rotation, and the top frame 2 is Rectangular frame, the top frame 2 is fixed on the top of the bottom groove 1, the slide frame 3 is slidably connected to the top frame 2, and the bottom end of the slide frame 3 is located in the bottom gro...

Embodiment 2

[0024] refer to figure 2 , the difference of this embodiment is that: the upper wire harness slot 12 is detachably connected to the lower part of the carriage 3 , and the lower wire harness slot 13 is detachably connected to the lower bottom surface of the bottom groove 1 .

[0025] In actual use: the connection line between the charging pile and the municipal power supply can be wired through the upper wire harness slot 12 and the lower wire harness slot 13 to prevent friction between the wire harness and the lead screw 6 .

Embodiment 3

[0027] refer to figure 1 , the difference of this embodiment is that: one side of the top frame 2 is detachably connected to a pair of first travel switches 14 , and the sliding frame 3 is located between the pair of first travel switches 14 .

[0028] In actual use: when the sliding frame 3 slides on the top frame 2, the moving range of the sliding frame 3 can be limited by the first travel switch 14, so as to prevent pulling the connection line between the charging pile and the municipal power supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com