Cylindrical lithium battery adhesive tape sticking mechanism and working method thereof

A working method and tape sticking technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, sustainable manufacturing/processing, etc., can solve the problems of relying on manual sticking of tapes, failing to realize automatic sticking of tapes, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

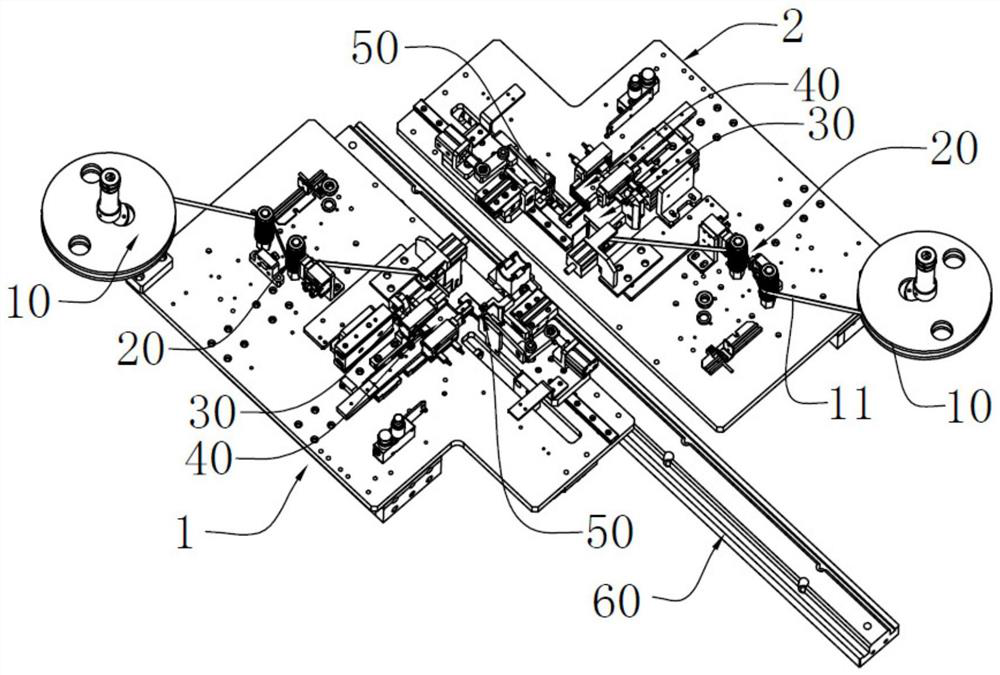

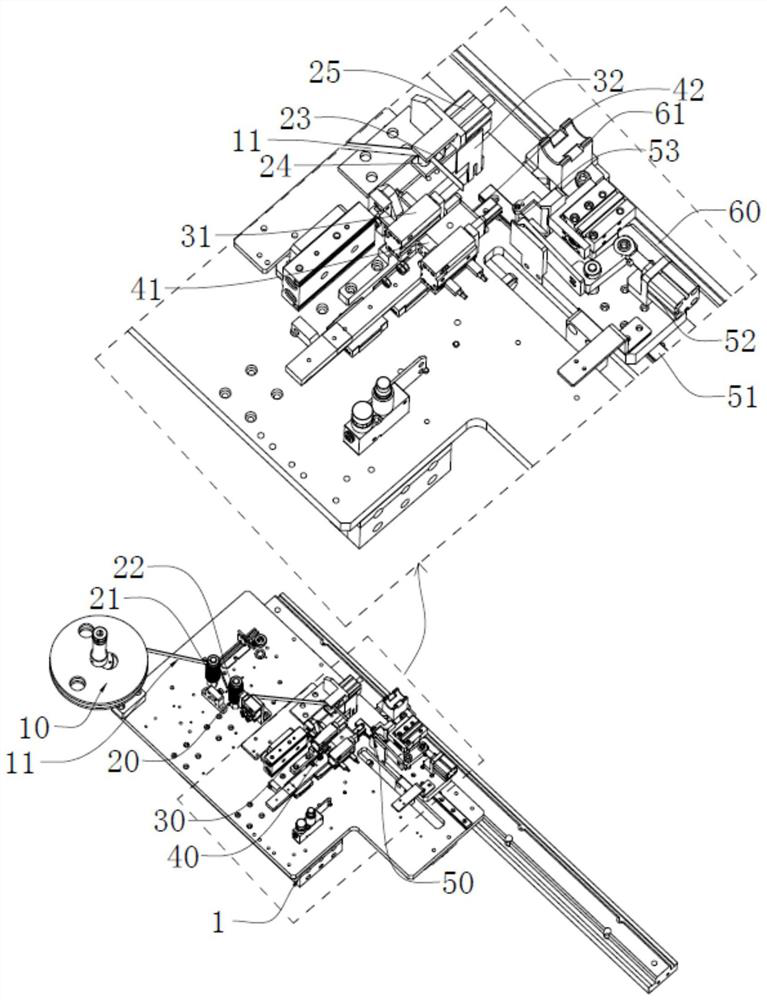

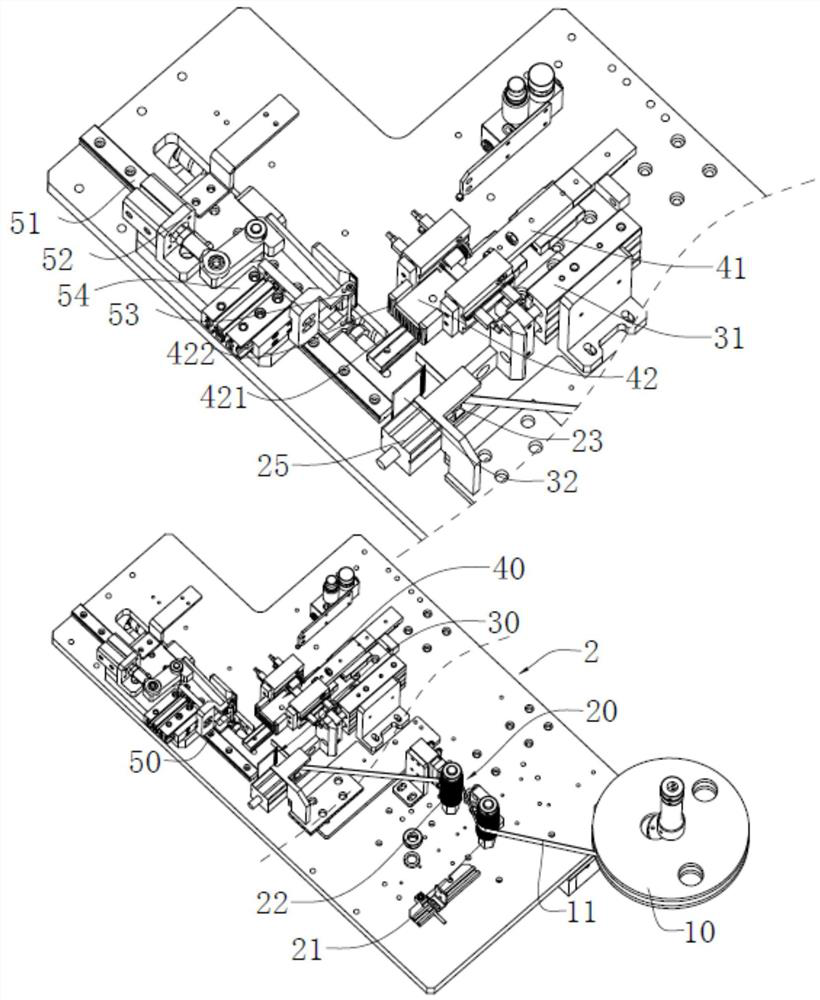

[0041] Such as Figure 1 to Figure 4 As shown, a cylindrical lithium battery tape sticking mechanism provided by the present invention includes a disc wheel 10 sequentially connected from upstream to downstream, a tape guide clamping mechanism 20, a cutting mechanism 30, a tape sticking mechanism 40, and a tape clamping mechanism 50 and battery delivery rail 60. Wherein, disc wheel 10 is used for supplying adhesive tape, and adhesive tape guide clamping mechanism 20 is used for guiding and clamping the adhesive tape on disc wheel 10, and adhesive tape clamping mechanism 50 is used for clamping the end of adhesive tape and pulls out, and adhesive tape pasting mechanism 40 is used for pasting the pulled-out adhesive tape on the battery, and the cutting mechanism 30 is used for cutting off the pasted adhesive tape.

[0042] Disc wheel 10, adhesive tape guiding clamping mechanism 20, cutting mechanism 30, adhesive tape sticking mechanism 40 and adhesive tape clamping mechanism 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com