Filter and vehicle

A filter and tank technology, applied in the field of filters, can solve problems such as the inability to use low-grade fuel for fuel supply, low-grade fuel tank mixing, fuel conversion valve sticking, etc., to reduce the risk of failure rate, Compact structure, anti-oil mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

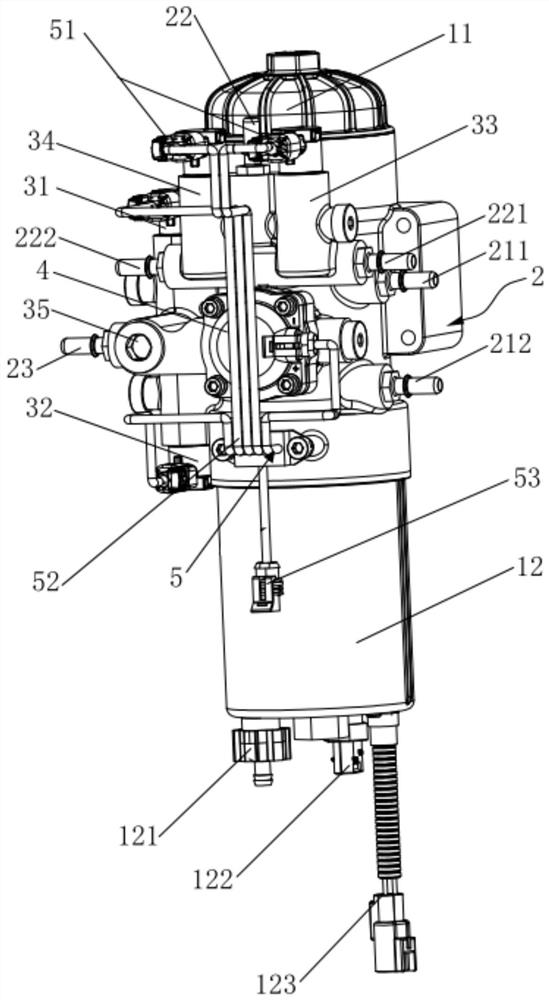

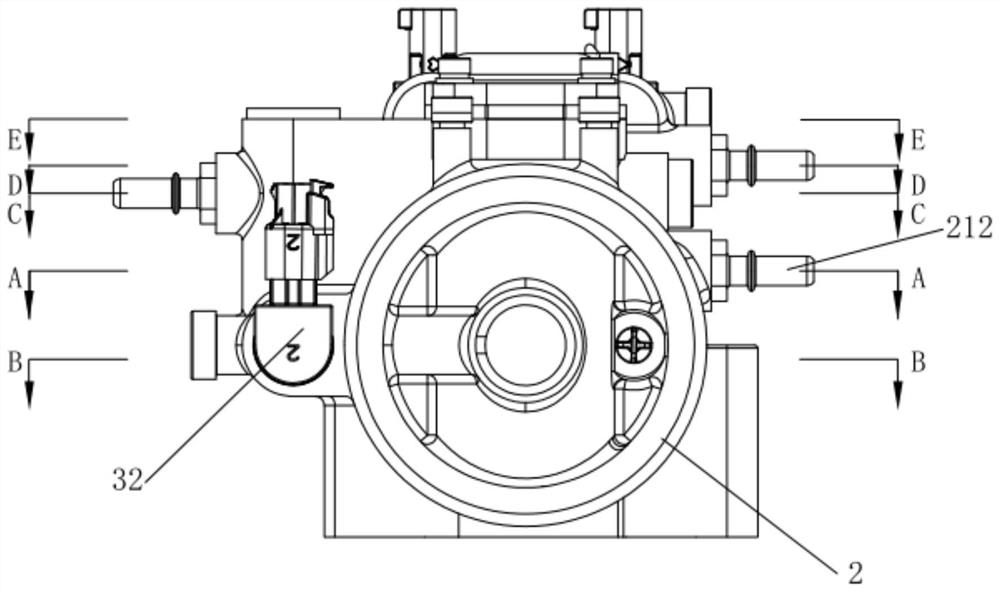

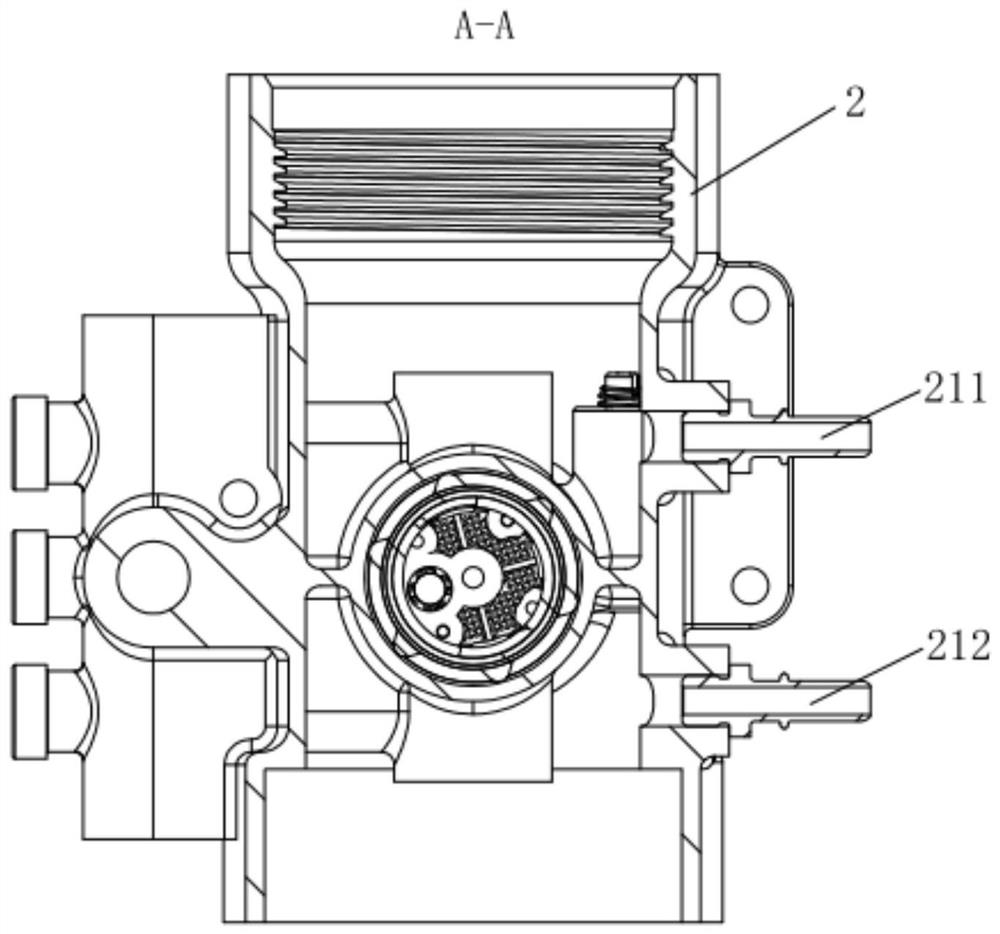

[0045] This embodiment provides a filter, such as figure 1 As shown, it includes an upper tank body 11, a lower tank body 12, a base 2 and a control valve assembly; specifically, the base 2 is fixedly arranged between the upper tank body 11 and the lower tank body 12, and the base 2 is provided with The oil inlet pipeline 21, the oil return pipeline 22 and the oil outlet pipeline 23, the oil inlet pipeline 21 communicates with the oil outlet pipeline 23, the oil outlet pipeline 23 communicates with the low-pressure oil pump, and the low-pressure oil pump can pump oil to the common rail system; the control valve assembly is arranged on On the base 2, the control valve assembly can control the oil inlet pipeline 21 to alternatively communicate with the lower tank body 12 and the main fuel tank, or communicate with the upper tank body 11 and the auxiliary fuel tank; the control valve assembly can control the oil return pipeline 22 to alternatively communicate with the main fuel ta...

Embodiment 2

[0066] This embodiment provides a filter, and the overall structure of the filter provided by this embodiment is basically the same as that of the filter in Embodiment 1, only the part of the control valve assembly is different, and this embodiment is no longer The same structure as that of the first embodiment will be described in detail.

[0067] The difference between this embodiment and Embodiment 1 is that, if Figure 8 As shown, the oil inlet control valve and the oil return control valve are two-position three-way solenoid valves, and the three channels of the first two-position three-way solenoid valve 36 are connected with the upper oil inlet 211, the lower oil inlet 212 and the oil inlet pipe respectively. The three passages of the second two-position three-way solenoid valve 37 are respectively connected with the upper oil return port 221, the lower oil return port 222 and the oil return line 22; the number of solenoid valves used is reduced from four to two One, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com