A filter and an oil supply method using the filter

A filter and filter tank technology, applied in the field of filters, can solve the problems of lack of accurate sequential control logic and time sequence, stuck fuel switching valve, and low reliability, so as to improve user experience and reliability , Improve the effect of work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

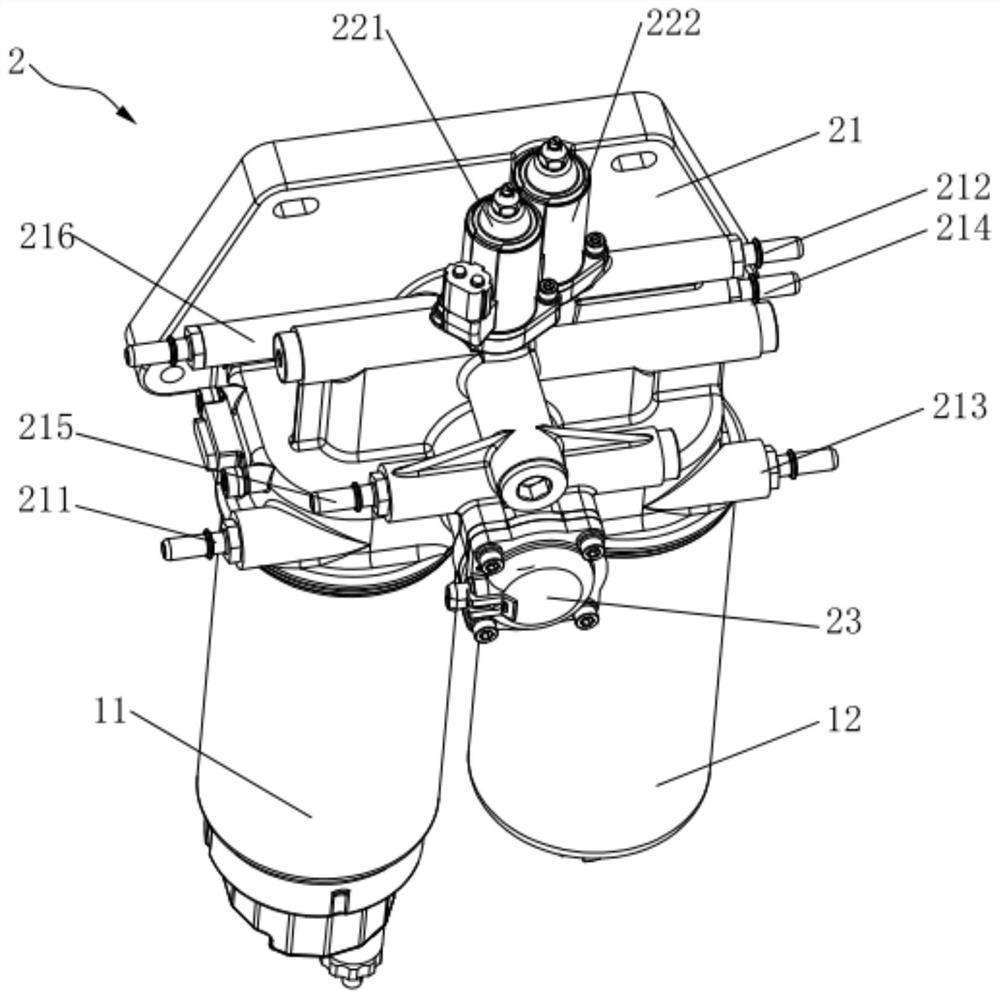

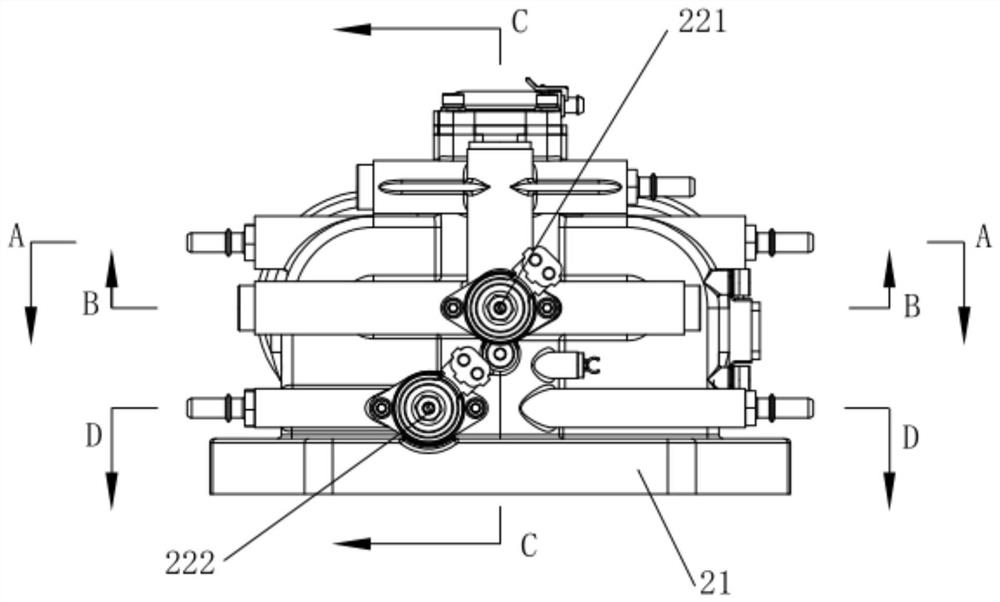

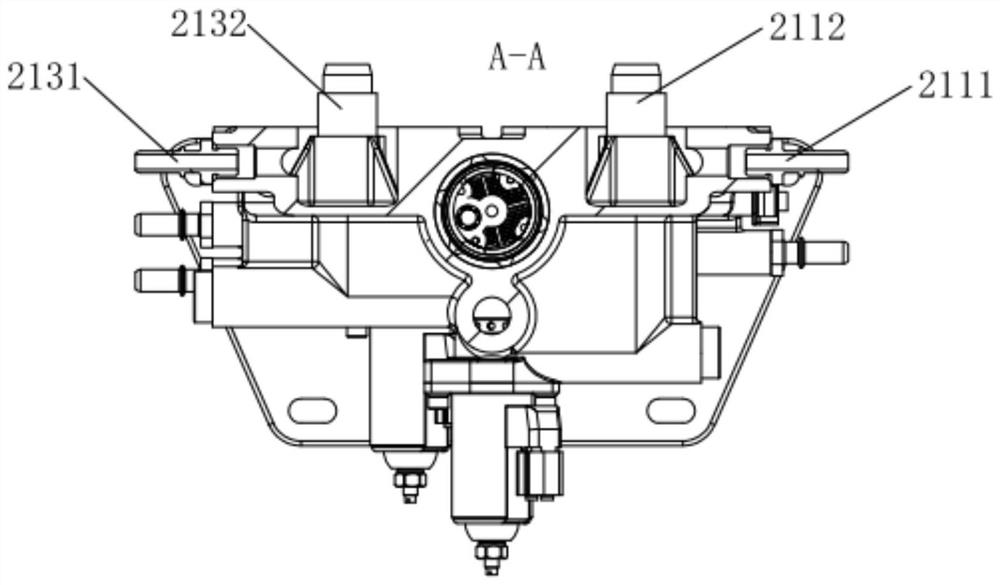

[0051] This embodiment provides a filter such as figure 1 As shown, it includes an assembly unit 2 and a first canister 11 and a second canister 12 arranged in parallel. The assembly unit 2 includes a base 21 , and the first canister 11 and the second canister 12 are both fixed to the base 21 The base 21 is provided with a first oil inlet pipe 211 , a first oil return pipe 212 , a second oil inlet pipe 213 , a second oil return pipe 214 and an oil outlet pipe 215 . Specifically, the first oil inlet pipe 211 can communicate with the first canister 11 and the main fuel tank; the first fuel return pipe 212 can communicate with the main fuel tank and the common fuel rail; the second fuel inlet pipe 213 can communicate with the second filter tank 12 and the auxiliary fuel tank; the second fuel return pipe 214 can communicate with the auxiliary fuel tank and the common fuel rail; the fuel outlet pipe 215 can The low-pressure oil pump is used to communicate with the first canister 11...

Embodiment 2

[0085] This embodiment provides a filter, and the overall structure of the filter provided in this embodiment is basically the same as that of the filter in Embodiment 1, and only some settings of the control valve group are different, and this embodiment does not The same structure as that of the first embodiment will be described in detail.

[0086] like Figure 7 As shown, the difference between this embodiment and the first embodiment is that the oil inlet control valve and the oil return control valve respectively include two one-way valves 224, and each one-way valve 224 is respectively arranged on the first oil inlet pipe 211 and the first oil return pipe. 212. On the second oil inlet pipe 213 and the second oil return pipe 214, that is, through the four check valves 224, the first oil inlet pipe 211, the first oil return pipe 212, the second oil inlet pipe 213, the second oil return pipe 214 and the outlet The oil pipes 215 are independently controlled, with simple st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com