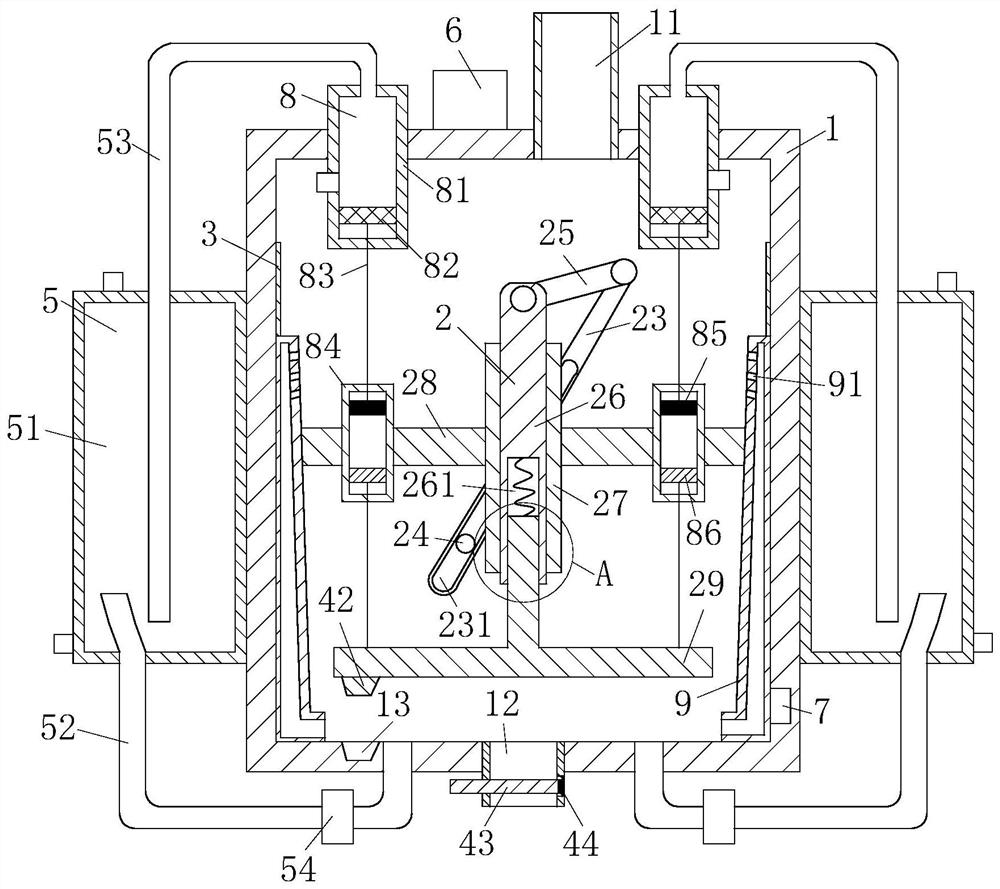

A reaction kettle for gear lubricating oil production

A technology of gear lubricating oil and reactor, applied in lubricating composition, chemical/physical/physicochemical fixed reactor, transportation and packaging, etc., can solve slow cooling speed, uneven cooling, affecting the quality of lubricating oil production, etc. problem, to achieve the effect of improving production quality, improving mixing effect, and efficient crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

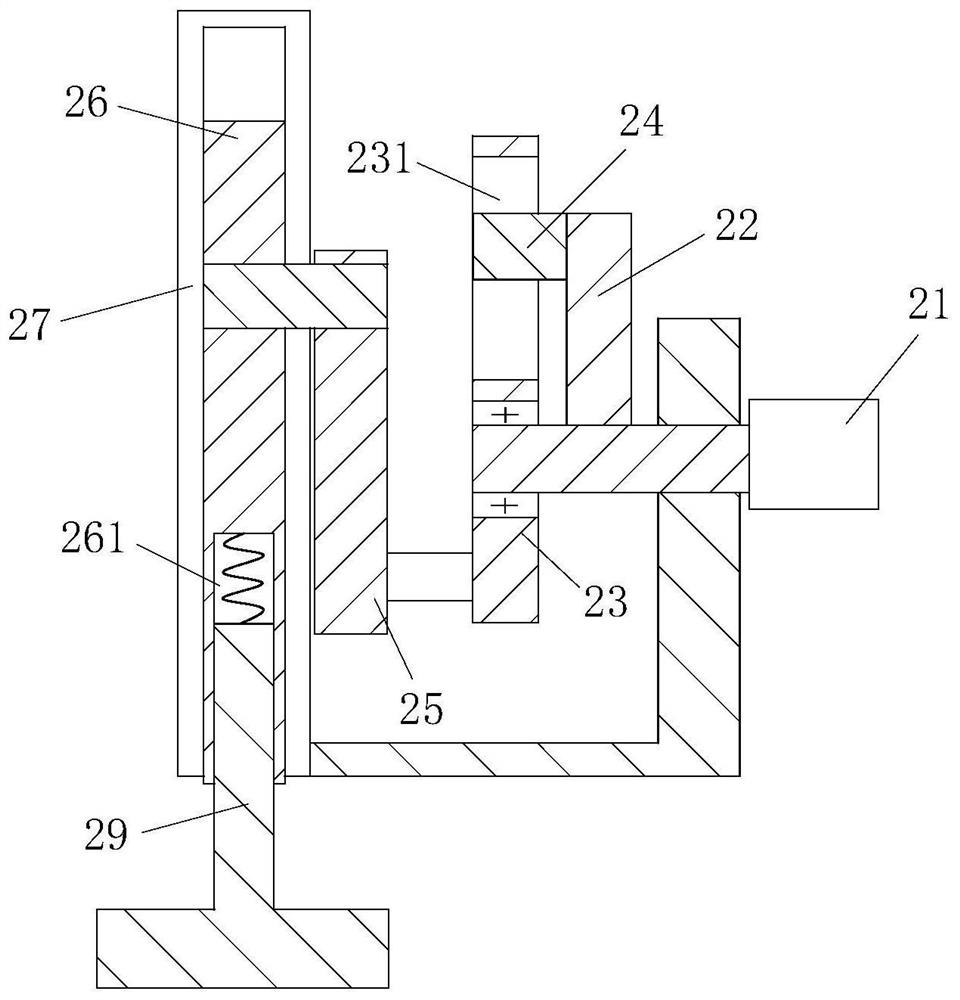

Method used

Image

Examples

Embodiment approach

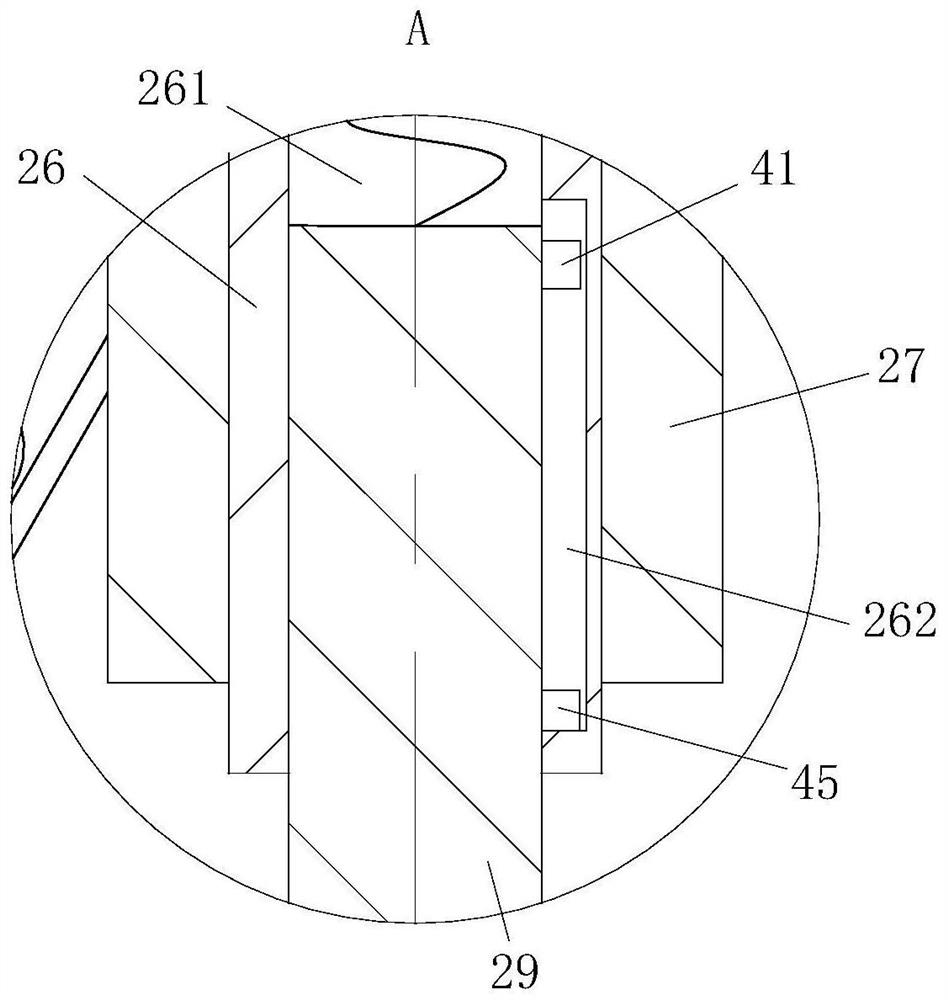

[0030] As an embodiment of the present invention, the opening diameter of the bottom end of the oil flow channel 9 is larger than the opening diameter of the top end; as the diameter of the oil liquid pipeline gradually decreases, the oil at the top of the oil liquid channel 9 sprays It is sprayed into the outer casing 1 to increase the spraying area of the oil, and further improve the sufficient mixing of the oil.

[0031] As an embodiment of the present invention, a spring 92 is provided inside the top of the oil flow channel 9, and a rubber sealing plug 93 is connected to the bottom of the spring 92, and the rubber sealing plug 93 is arranged in the oil flow channel 9; When the oil in the oil flow channel 9 gradually increases, the oil squeezes the rubber sealing plug 93, which in turn compresses the spring 92, so that the oil is ejected from the liquid injection port 91 at a higher and faster speed. The spring 92 functions to maintain the pressure.

[0032] The specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com