A Gradient Coil with Parallel Structure

A technology of gradient coils and coils, which is applied to the measurement of magnetic variables, instruments, measuring devices, etc., can solve the problems of low reliability and high manufacturing cost of gradient coils, reduce the difficulty of design and manufacturing, improve image quality, and achieve high gradient linearity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] In the following description, specific details are set forth in order to provide a thorough understanding of the present invention. However, the present invention can be implemented in many other ways than those described here, and those skilled in the art can make similar extensions without departing from the connotation of the present invention. Accordingly, the present invention is not limited to the specific embodiments disclosed below.

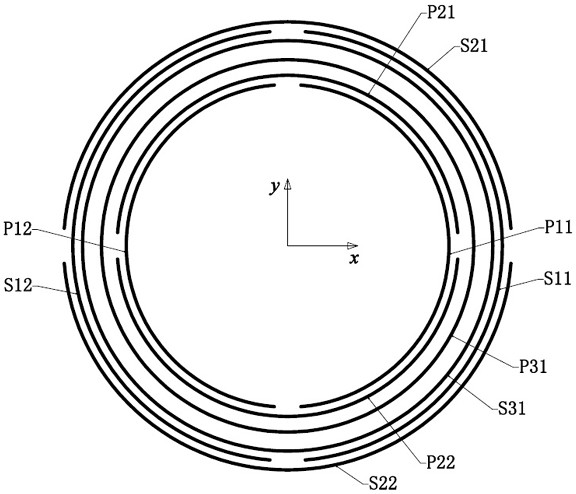

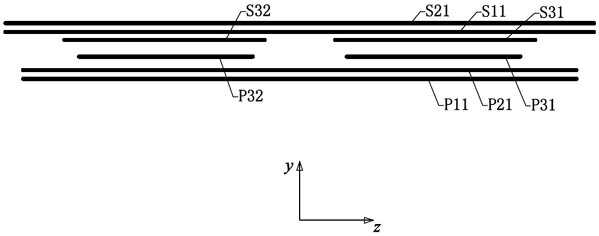

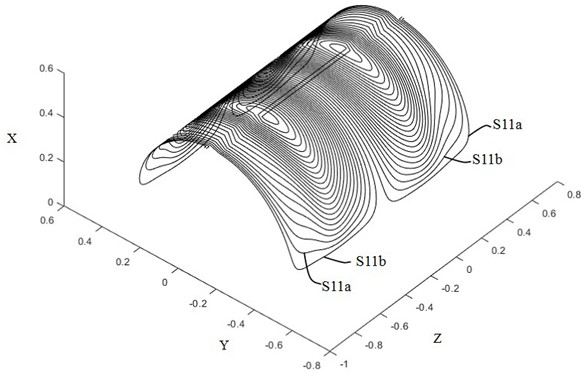

[0034] Please refer to Figure 1~Figure 5 , figure 1 is a schematic diagram of the cross-section level of the gradient coil; figure 2 is a schematic diagram of the longitudinal section position of the gradient coil; image 3 is a schematic structural diagram of the first shi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap