A kind of ultrasonic power supply and its power supply method

A technology of ultrasonic and power supply, which is applied in the field of ultrasonic power supply and its power supply, and can solve problems such as poor linearity of output power and poor working stability of ultrasonic power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0056] The above is a first embodiment of an ultrasonic power supply provided by an embodiment of the present application, and the following is a second embodiment of an ultrasonic power source provided by an embodiment of the present application.

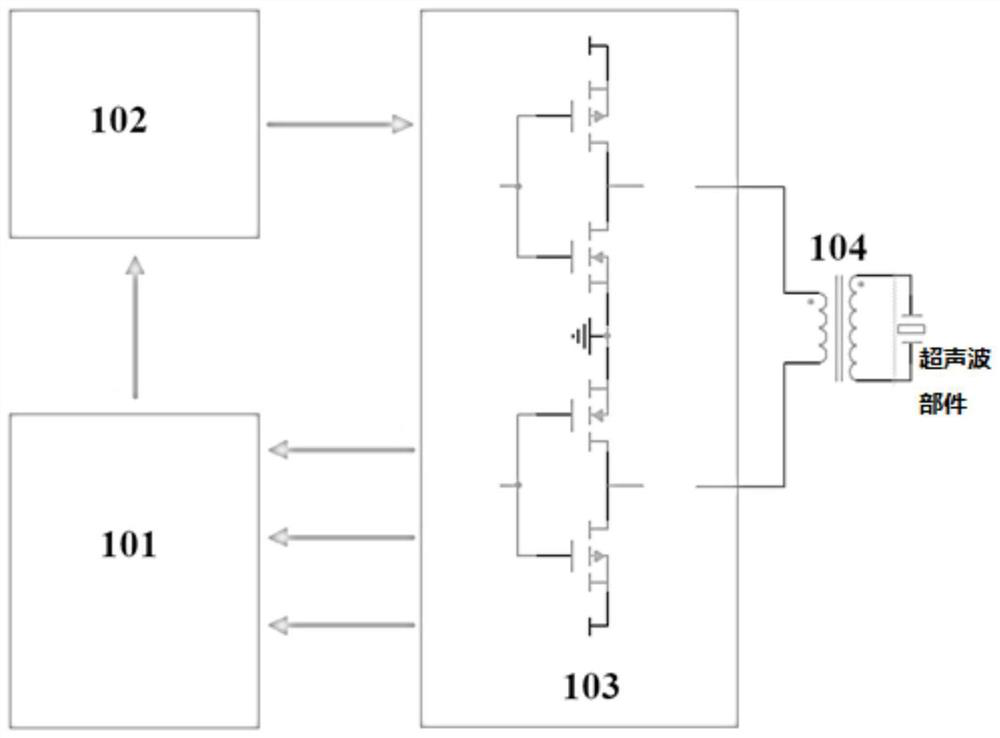

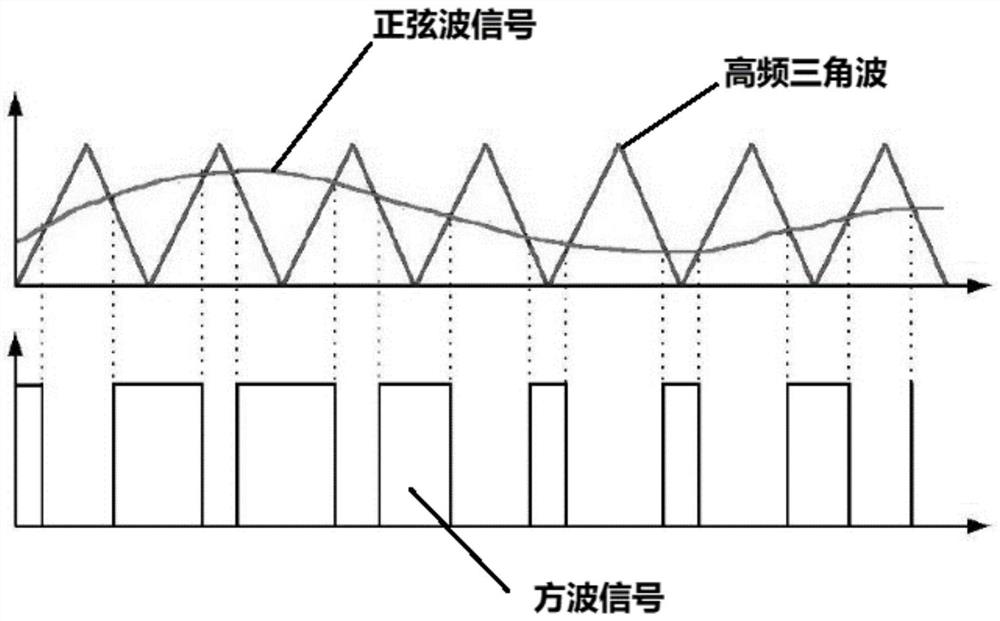

[0057] The ultrasonic power supply in the second embodiment includes: a main control unit 101, a first modulator 102, a power amplifier 103 and a coupler 104; the main control unit 101 is used to generate a preset signal; the first modulator 102 is used to The preset signal is subjected to pulse width modulation to obtain electrical pulses; specifically, the first modulator 102 is a sine wave modulator, and the sine wave modulator is specifically used to perform pulse width modulation on a sine wave to obtain electrical pulses; the power amplifier 103, It is used to amplify the electric pulse, and output the amplified electric pulse to the coupler 104; the output end of the coupler 104 is used to connect the ultrasonic component.

...

Embodiment approach

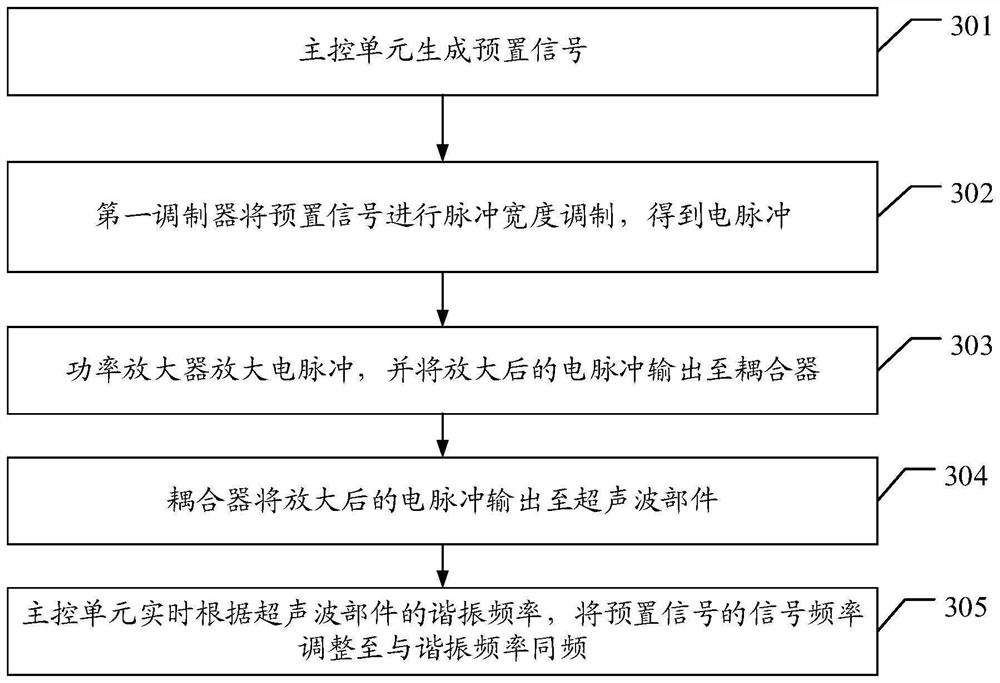

[0082] Obtain the resonant current of the ultrasonic component in real time, wherein the resonant current is the current of the ultrasonic component at the resonant frequency;

[0083] Calculate the current absolute value of the current difference between the resonant current and the signal current corresponding to the preset signal;

[0084] When it is determined that the absolute value of the current is greater than the second preset (preset current threshold), the signal current corresponding to the preset signal is adjusted to be equal to the resonant current, so that the frequency of the adjusted signal is the same as the resonant frequency.

[0085] It should be noted that, as can be seen from the above, the signal frequency adjustment of the preset signal can be realized by adjusting the signal frequency or by adjusting the signal current, and those skilled in the art can choose as needed.

[0086] like Figure 4 As shown, acquiring the resonant frequency of the ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com