Automatic edge trimmer

An edge trimming machine, automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low product qualification rate, low production efficiency, personnel injury, etc., to achieve high qualified rate, smooth and accurate cutting process , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

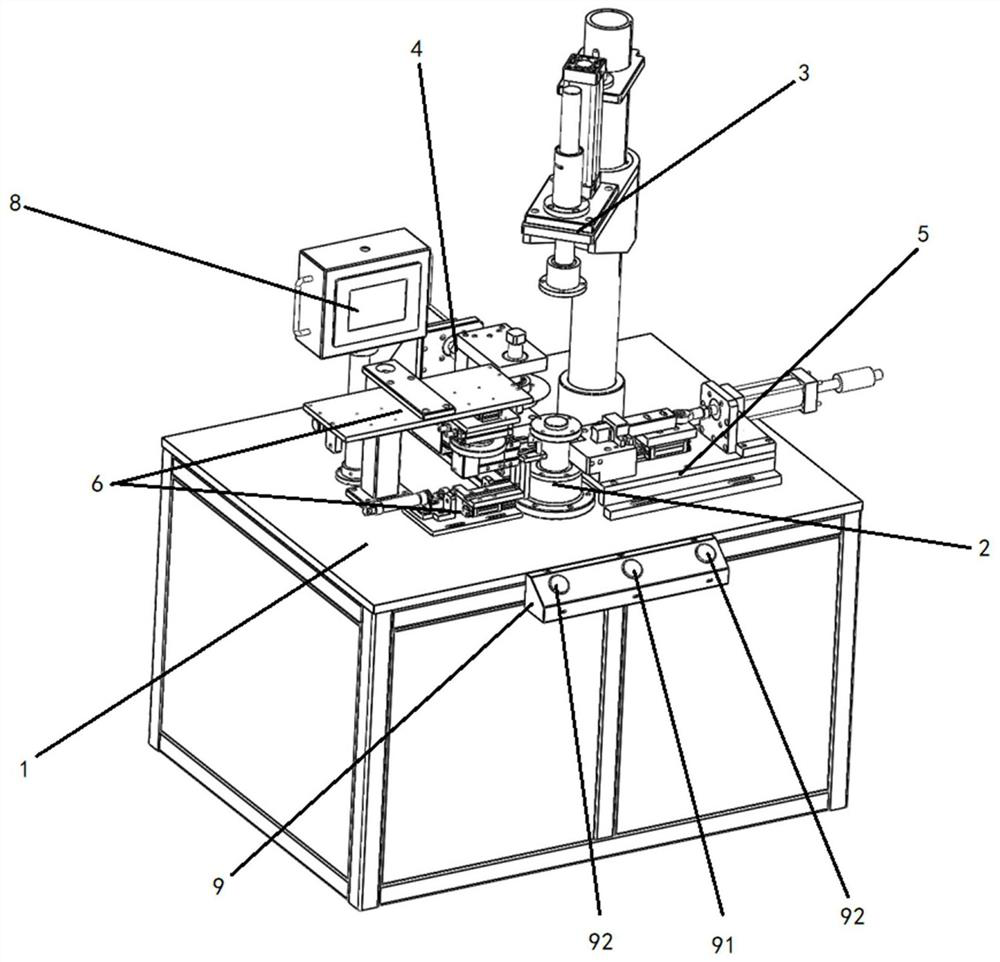

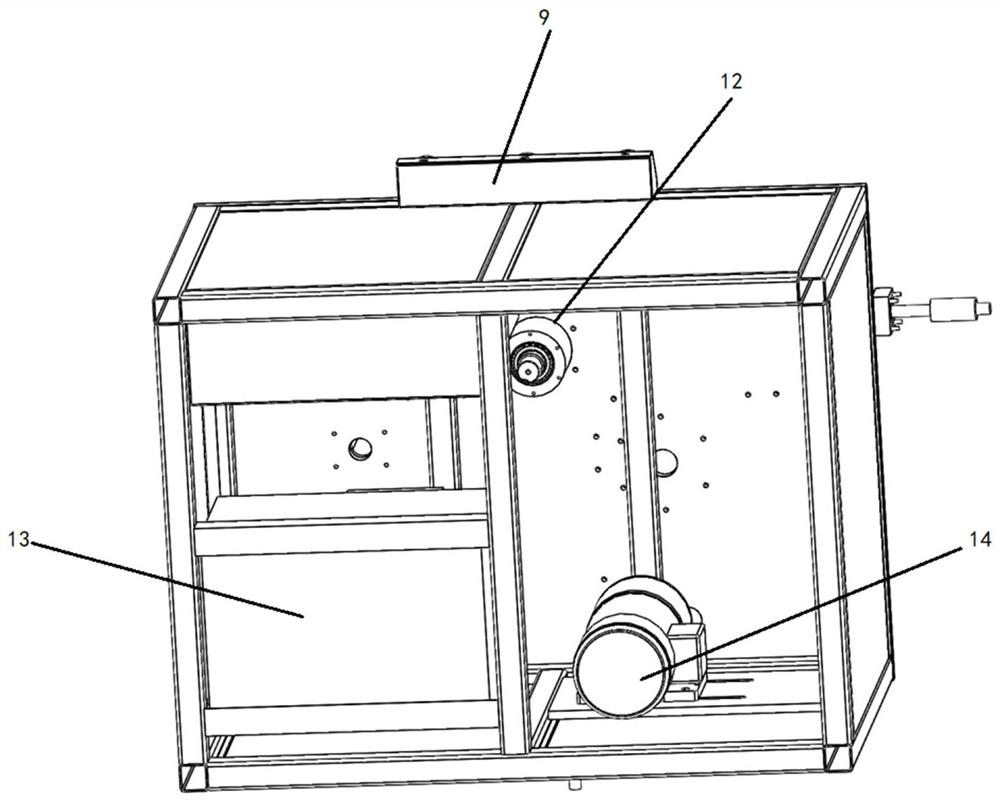

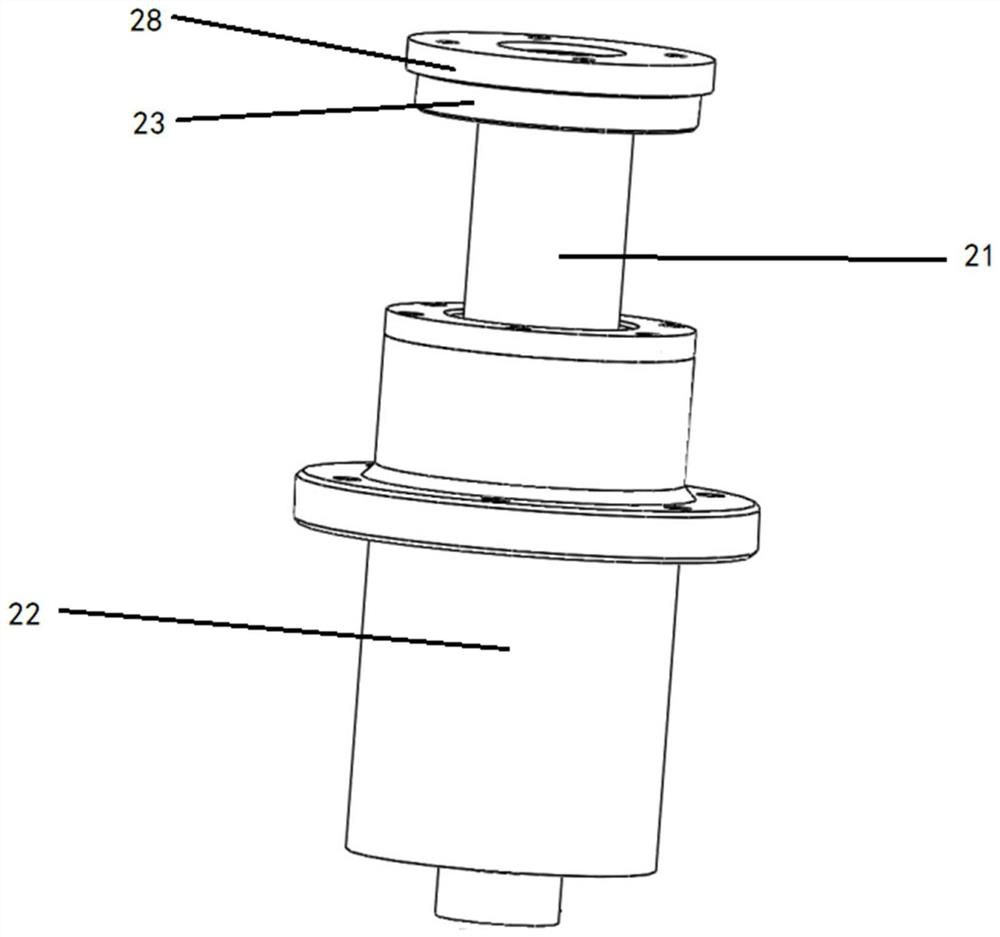

[0049] Such as figure 1 As shown, the present invention discloses an automatic edge trimming machine, comprising a main shaft rotating mechanism 2, a pressing mechanism 3, a cutting mechanism 4, a waste material cutting mechanism 5, a waste material clamping and dismounting mechanism 6 and a frame structure 1; the main shaft rotates The mechanism 2, the pressing mechanism 3, the cutting mechanism 4, the waste cutting mechanism 5 and the waste clamping and dismounting mechanism 6 are all arranged on the frame structure 1, and the pressing mechanism 3, the cutting mechanism 4, the waste cutting mechanism 5 and the waste clamping The dismantling mechanism 6 is all arranged on the periphery of the main shaft rotation mechanism 2, and the upper pressing mechanism 3 fixes the workpiece on the main shaft rotating mechanism 2, and the upper pressing cylinder 304 of the upper pressing mechanism 3 drives the upper pressing guide rod 305 to compress it; The trimming oil cylinder 407 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com