Scraper conveyer

A scraper conveyor and scraper technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of inconvenient disassembly and assembly, and achieve the effect of improving safety, easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

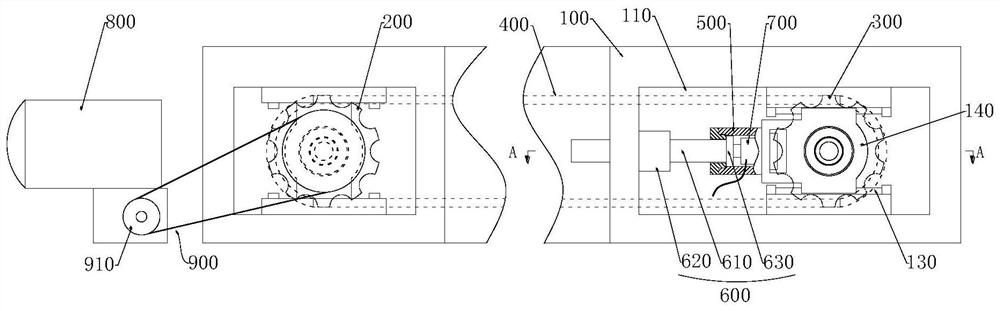

[0052] Such as figure 1 As shown, a scraper conveyor has two sprocket assemblies oppositely arranged on its frame 100, and the same scraper chain 400 is sleeved on the two sprocket assemblies, and the two sprocket assemblies They are respectively a driving sprocket assembly 200 and a driven sprocket assembly 300 , wherein the driving sprocket assembly 200 is rotatably mounted on the frame 100 and driven to rotate by a driving device 800 . A driven shaft seat 140 is slidably disposed on the frame 100, and the driven sprocket assembly 300 is rotatably mounted on the driven shaft seat 140. Between the driven shaft seat 140 and the frame 100, a The linear telescopic mechanism 600 is used to adjust the distance between the two sprocket assemblies.

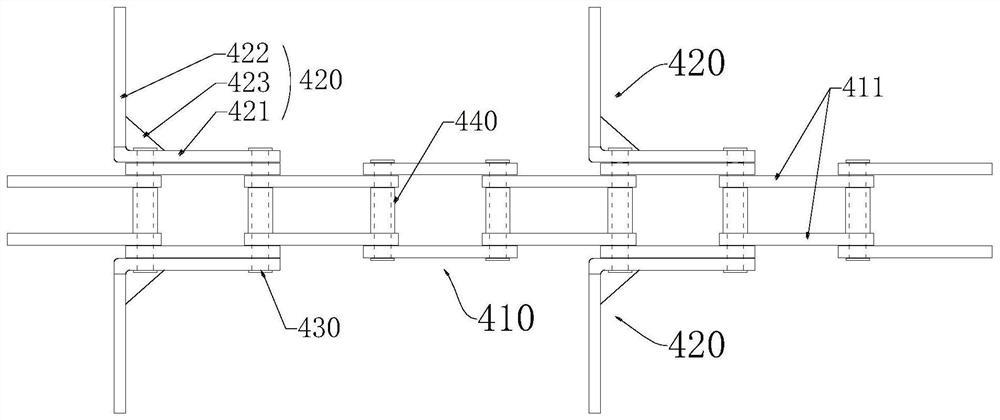

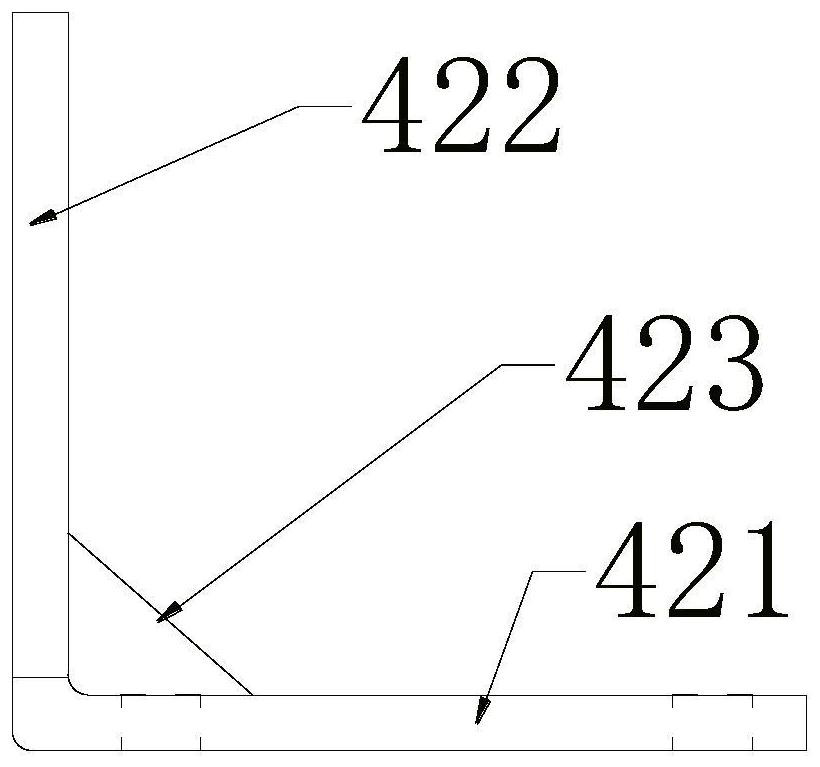

[0053] Such as figure 2 As shown, the scraper chain 400 includes a number of chain link units 410 arranged in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com