Hanging bracket structure capable of being freely disassembled and assembled and splicing mode

A group structure and free technology, applied in the connection of rods, connecting components, transportation and packaging, etc., can solve the problems of waste of resources and inability to use the next project, so as to save resources, improve the ability to bear loads, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

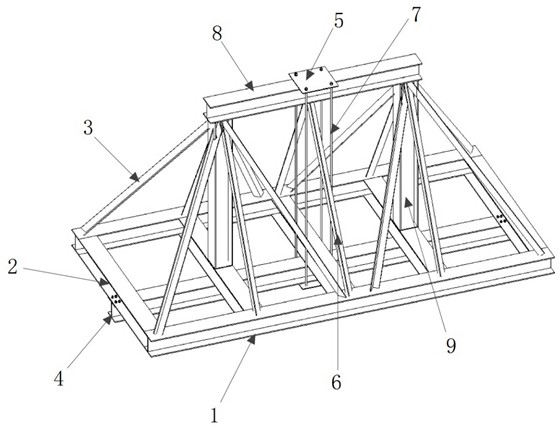

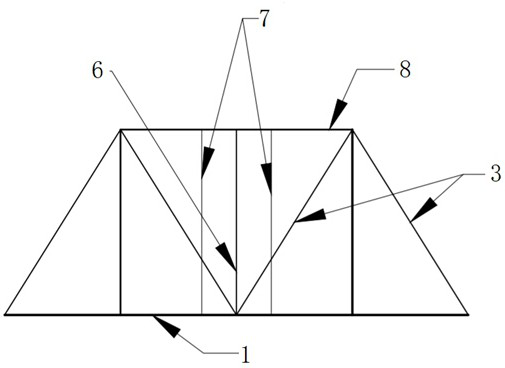

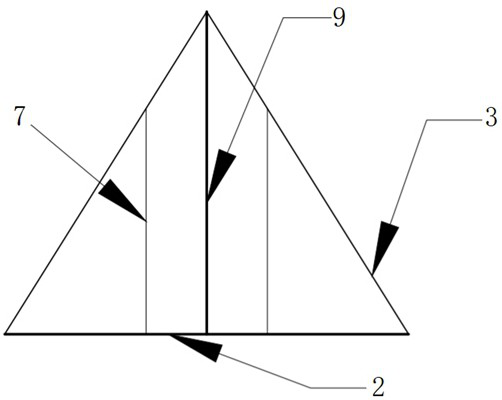

[0041] like Figure 1 to Figure 12The hanger structure and splicing method shown in the present invention that can be freely disassembled and assembled includes a hanger device composed of multiple sets of structural units, and I-beams and angle steels that constitute the structural units. The I-beams include transverse I-beams I-beam one 1, vertical I-beam one 2, horizontal I-beam two 4, horizontal I-beam three 8 and vertical I-beam one 9, angle steel includes No. 1 angle steel 3, No. 2 angle steel 6 and No. 3 angle steel 13. Stiffeners are provided on the horizontal I-beam-1. The setting of the stiffeners ensures the overall stability, and are arranged at equal intervals on the horizontal I-beam-1. There are at least two horizontal I-beam-1. , there are at least two vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com