A kind of black polyimide film containing high compatibility pigment and preparation method thereof

A technology of polyimide film and polyimide matrix, which is applied in the field of black polyimide masking film, black polyimide film and its preparation, can solve the problem of reducing the insulation and mechanical properties of polyimide film, Increase production costs, affect performance and other issues, to achieve the effect of wide applicability and application promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation of polyamic acid resin solution. Polyamic acid resin can be prepared by copolymerization of dianhydride and diamine. Wherein, the diamine can be phenylenediamine, diaminodiphenyl ether or derivatives thereof, and the like. Specific examples of diamines include: p-phenylenediamine, o-phenylenediamine, m-phenylenediamine, 3,4-diaminodiphenyl ether, 2,4-diaminodiphenyl ether, 4,4'- Diaminodiphenyl ether (ODA), etc. Examples of dianhydrides include: biphenylcarboxylic dianhydride or derivatives thereof, and pyromellitic dianhydride or derivatives thereof. Specific examples of dianhydrides may include 3,3',4,4'-biphenyltetracarboxylic dianhydride, pyromellitic dianhydride, 3,3',4,4'-benzophenone tetracarboxylic dianhydride , p-phenylene-bistrimellitic dianhydride, etc., preferably 3,3',4,4'-biphenyltetracarboxylic dianhydride and pyromellitic diketone. In particular, 3,3',4,4'-biphenyltetracarboxylic dianhydride or pyromellitic dianhydride.

[0038] The disp...

Embodiment 1

[0045] Embodiment 1: the preparation of polyimide film

[0046] Experimental raw materials: N,N-dimethylacetamide (DMAc), pyromellitic dianhydride (PMDA), 4,4’-diaminodiphenyl ether (ODA);

[0047] Experimental equipment: double-layer glass reactor, circulating cooler, electric stirrer;

[0048] When preparing polyamic acid, the solid content of the control system was about 20%, and the temperature of the circulating cooler was set at 25°C during the experiment. Add 40g DMAc to the double-layer glass reactor, add 4.786g ODA, start the electric stirrer and stir until the ODA is completely dissolved. Divide 98% PMDA in an equimolar amount (5.214g) with ODA into two parts, slowly add the first part of dianhydride into the reactor, and stir for 10-15 minutes until the reaction is completely exothermic. Then slowly add the second part of dianhydride into the reactor, and stir for 30 minutes until the reaction is completely no longer exothermic. The remaining 2% ODA molar amount ...

Embodiment 2

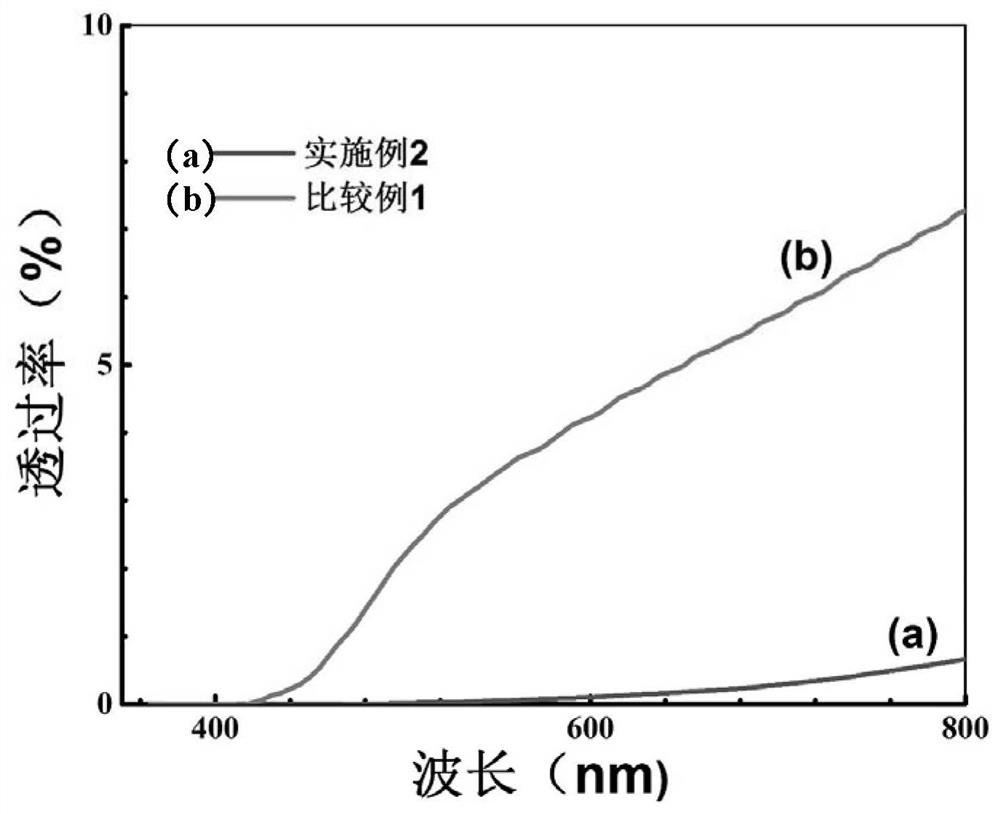

[0051] Embodiment 2: the preparation of black polyimide film

[0052] Carbonization of polyimide: take 10 g of the polyimide film prepared in Example 1, put it into a crucible, and raise the temperature from room temperature to 900° C. within 2 hours under the protection of circulating nitrogen gas, and keep it warm for 4 hours to obtain a black product;

[0053] Preparation of black slurry: 2g of the product obtained in the above steps, 0.1g of dispersant Merck MOK-5032 (5% of the solid mass), 18g of N,N-dimethylacetamide (DMAc), 20g of yttrium stabilizer with a diameter of 0.3mm Add zirconia grinding balls into a 100ml high-energy ball mill jar, and grind for 2 hours to obtain a black slurry. Detected by a laser particle size analyzer, the particle size is 18nm (D90);

[0054] Preparation of black polyimide film: it is basically the same as the method for preparing polyimide film in Example 1, except that 35g of the 40g DMAc used in the system is used for the dissolving of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com