A kind of preparation method and application of hybrid fluorescent paint based on cuprous iodide

The technology of cuprous iodide and fluorescent paint is applied in the field of fluorescent paint, which can solve the problems of uneven luminescent particles, difficult regulation of performance, uneven luminescence, etc., and achieves the effects of simple film forming process, low cost and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

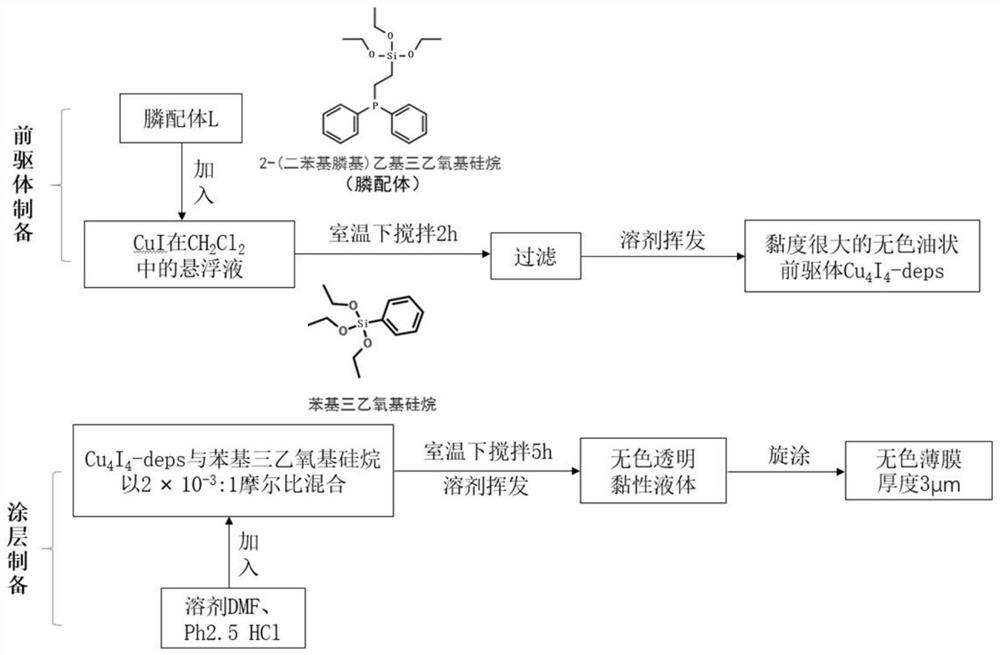

[0032] Embodiment 1 A kind of preparation method of hybrid fluorescent paint based on cuprous iodide

[0033] (1) Cuprous iodide silane precursor Cu 4 I 4 -Synthesis of dpes: To a suspension of CuI (0.5 g, 2.62 mmol) in 10 mL of dichloromethane at room temperature was added 2-(diphenylphosphino)ethyltriethoxysilane—a phosphine ligand L (1g, 2.66mmol), after the mixed solution was magnetically stirred at a speed of 400r / min at room temperature for 2h, the mixture was filtered, and after the solvent evaporated, a colorless oil with a high viscosity was obtained, i.e. cuprous iodide silane precursors. Yield = 77% (1.16 g, 0.5 mmol). The precursor emits orange light under UV excitation.

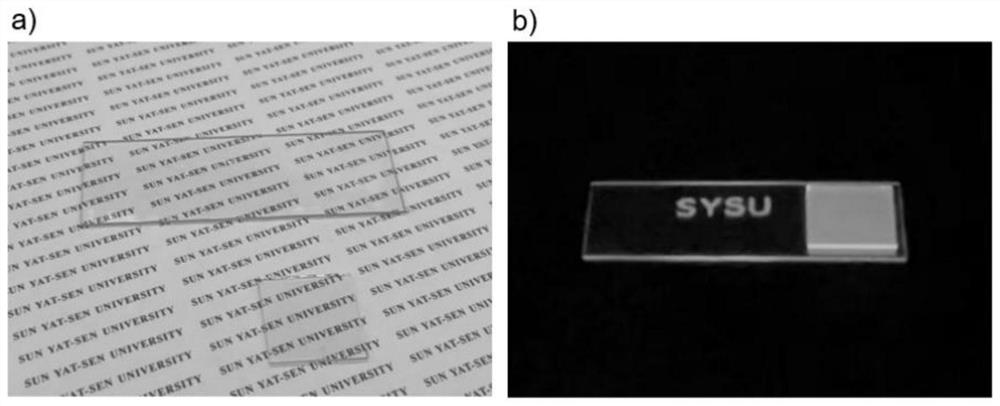

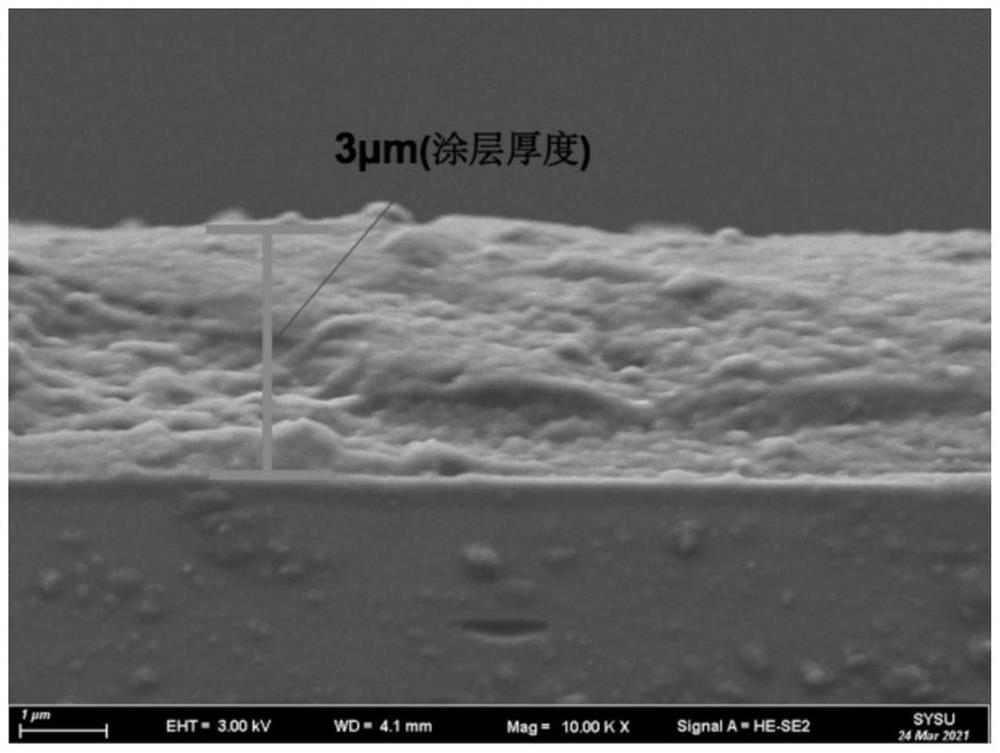

[0034] (2) Preparation of hybrid fluorescent coatings by sol-gel method: at room temperature, 1.16g Cu 4 I 4 -dpes precursor mixed with 60g phenyltriethoxysilane (molar ratio is 2×10 -3 : 1), add 60mL of solvent N,N-dimethylformamide (DMF), 7mL of HCl (hydrochloric acid) at pH 2.5, stir ma...

Embodiment 2

[0036] Embodiment 2 A kind of preparation method of hybrid fluorescent paint based on cuprous iodide

[0037] (1) Cuprous iodide silane precursor Cu 4 I 4 -Synthesis of dpes: To a suspension of CuI (0.1 g, 0.53 mmol) in 10 mL of dichloromethane at room temperature was added 2-(diphenylphosphino)ethyltriethoxysilane—a phosphine ligand L (0.2g, 0.53mmol), after the mixed solution was stirred at room temperature for 2h, the mixture was filtered, and after the solvent evaporated, a colorless oily substance with a high viscosity was obtained, that is, a cuprous iodide silane precursor. Yield = 83% (0.25 g, 0.11 mmol). The precursor emits orange light under UV excitation.

[0038] (2) Preparation of hybrid fluorescent coatings by sol-gel method: at room temperature, with 0.25g Cu 4 I 4 -dpes precursor mixed with 13g phenyltriethoxysilane (molar ratio is 2×10 -3 : 1), add 13mL of solvent N,N-dimethylformamide (DMF), 1.5mL of HCl at pH2.5, stir for 5h, and wait for the solvent to ...

Embodiment 3

[0040] Embodiment 3 A kind of preparation method of hybrid fluorescent paint based on cuprous iodide

[0041] (1) Cuprous iodide silane precursor Cu 4 I 4 -Synthesis of dpes: To a suspension of CuI (0.05 g, 0.26 mmol) in 10 mL of dichloromethane at room temperature was added 2-(diphenylphosphino)ethyltriethoxysilane—a phosphine ligand L (0.1g, 0.26mmol), after the mixed solution was stirred at room temperature for 2h, the mixture was filtered, and after the solvent evaporated, a colorless oily substance with high viscosity was obtained, that is, a cuprous iodide silane precursor. Yield = 81% (0.122 g, 0.05 mmol). The precursor emits orange light under UV excitation.

[0042] (2) Preparation of hybrid fluorescent coatings by sol-gel method: at room temperature, with 0.122g Cu 4 I 4 -dpes precursor mixed with 6.3g phenyltriethoxysilane (mole ratio is 2×10 -3 : 1), add 6.3mL of solvent N,N-dimethylformamide (DMF), 0.7mL of HCl with pH2.5, stir for 5h, and wait for the solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com