Complex multi-curve aluminum plate enclosure system and manufacturing method thereof

A manufacturing method and technology of aluminum plates, which are applied to building components, coverings/linings, walls, etc., can solve problems such as complex and multi-curved aluminum plate enclosure systems, difficulties in accurate positioning of keel connections, and difficulty in controlling the accuracy of architectural modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

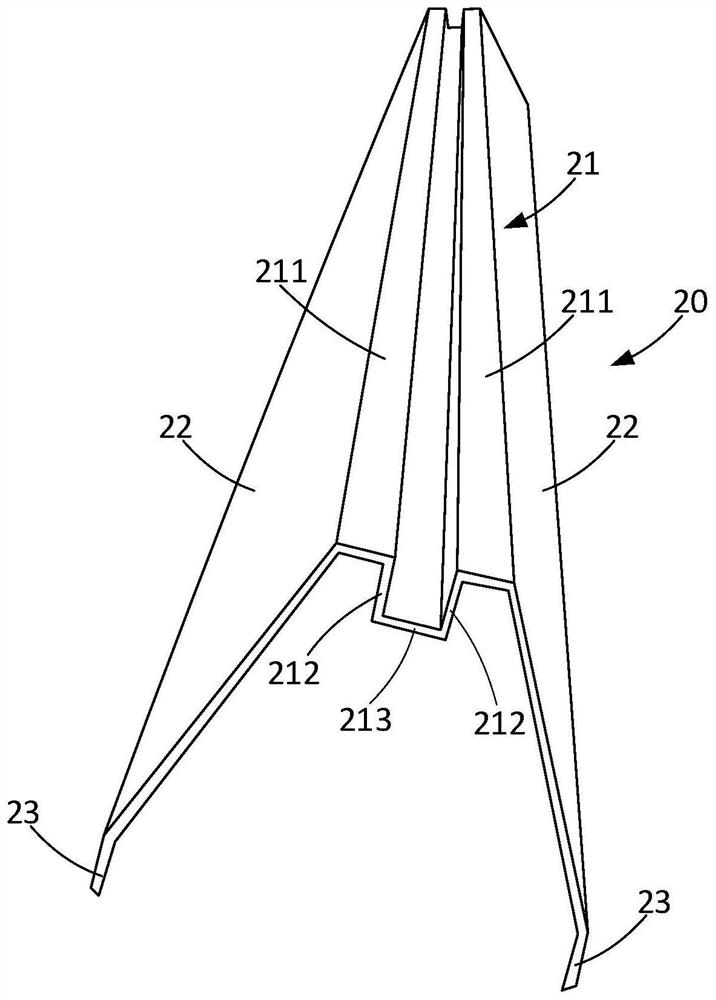

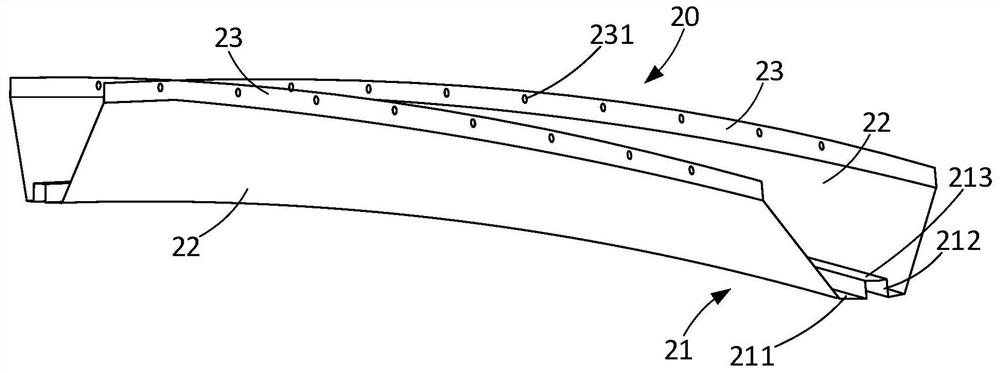

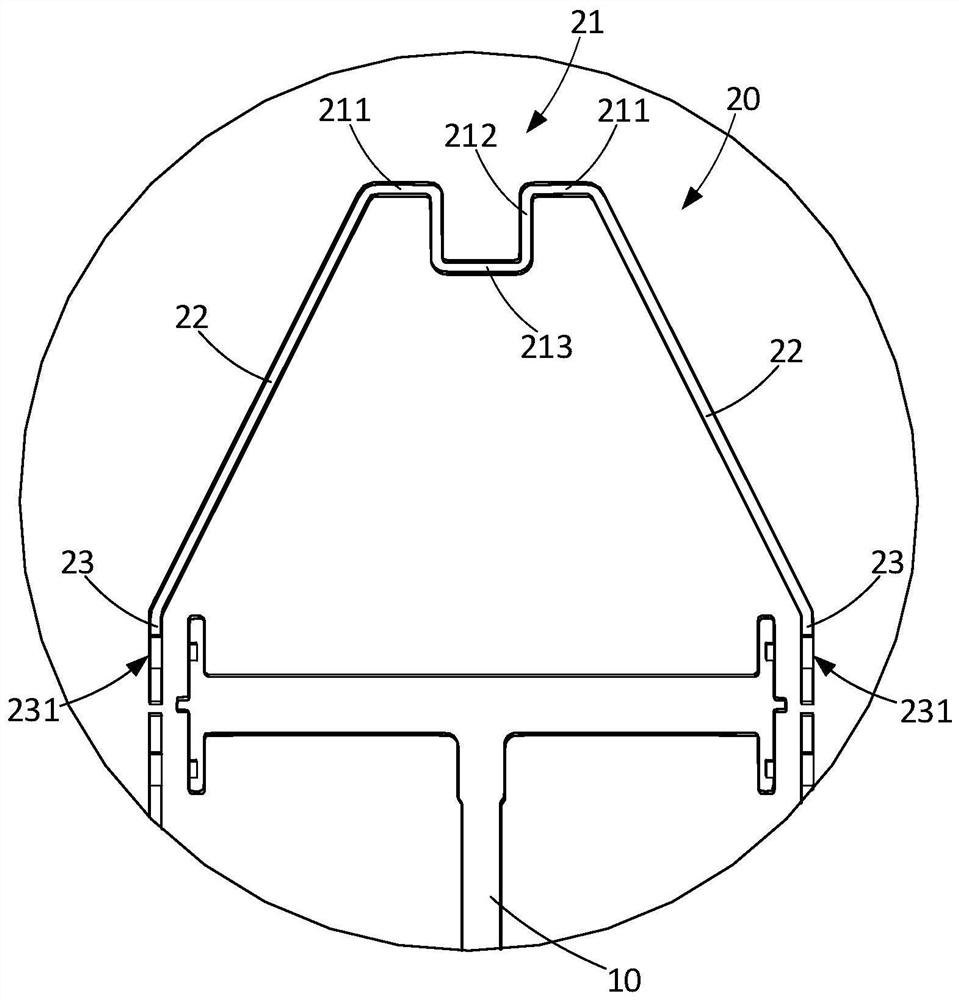

[0043] refer to figure 1 , the present invention provides a complex multi-curved aluminum plate enclosure system and its manufacturing method, which are used to realize the enclosure of a three-dimensionally twisted main structure, and the enclosure system can be directly installed and fixed on the main structure without setting a keel Connection, thus avoiding various problems existing in the traditional keel connection. The containment system of the present invention is bent and twisted as a whole, and each component is also bent and twisted so that its shape matches the shape of the three-dimensional twisted main structure. The enclosure top plate in the enclosure system of the present invention is provided with grooves, and the impact resistance of the enclosure top plate can be improved through the arrangement of the grooves, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com