Synchronous action shaft flow distribution switch reversing multi-way valve

A synchronous action, shaft distribution technology, applied in sliding valves, multi-port valves, valve devices, etc., can solve problems such as actuator failure, restricting flow capacity, affecting output power characteristics, etc., to reduce mechanical contact wear and eccentric wear. hidden dangers, realize the gap sealing length, and ensure the effect of long-term effective work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

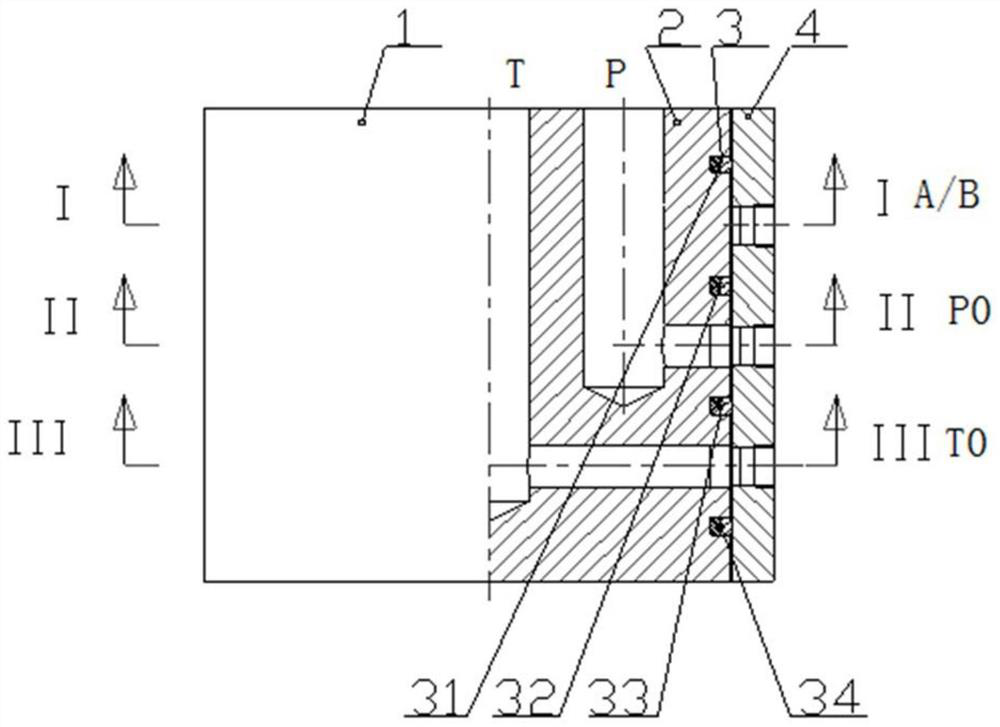

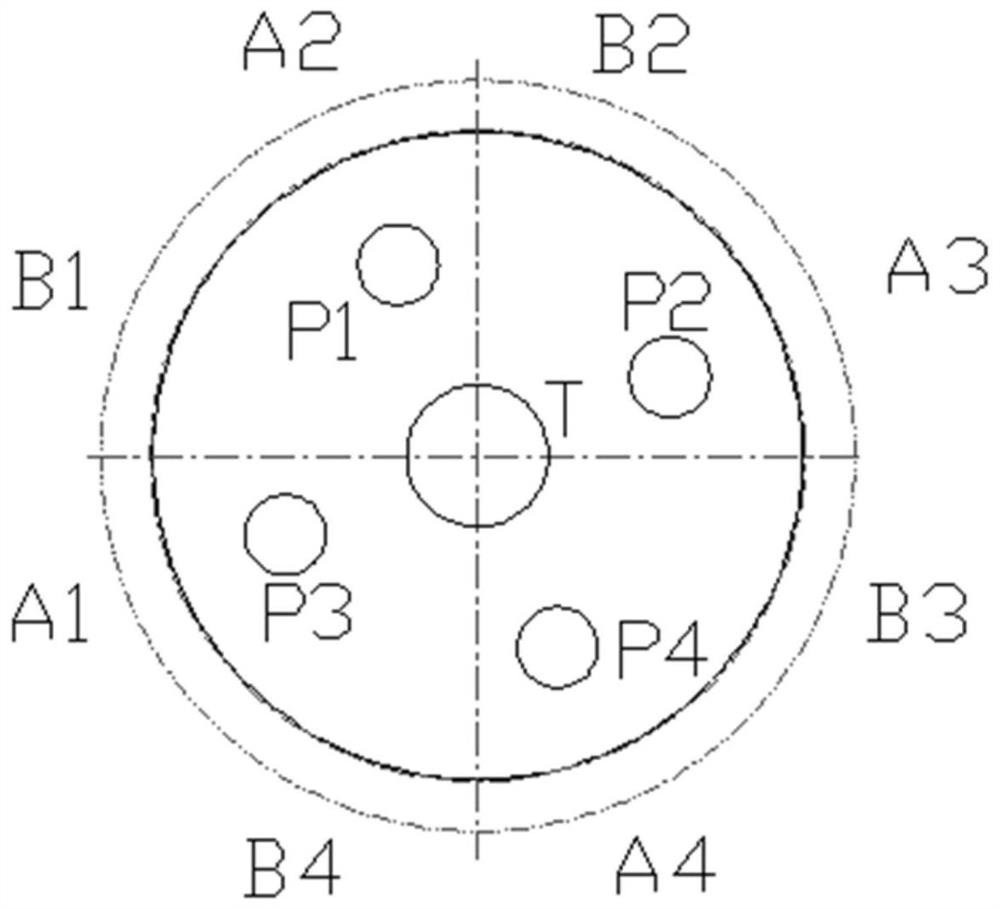

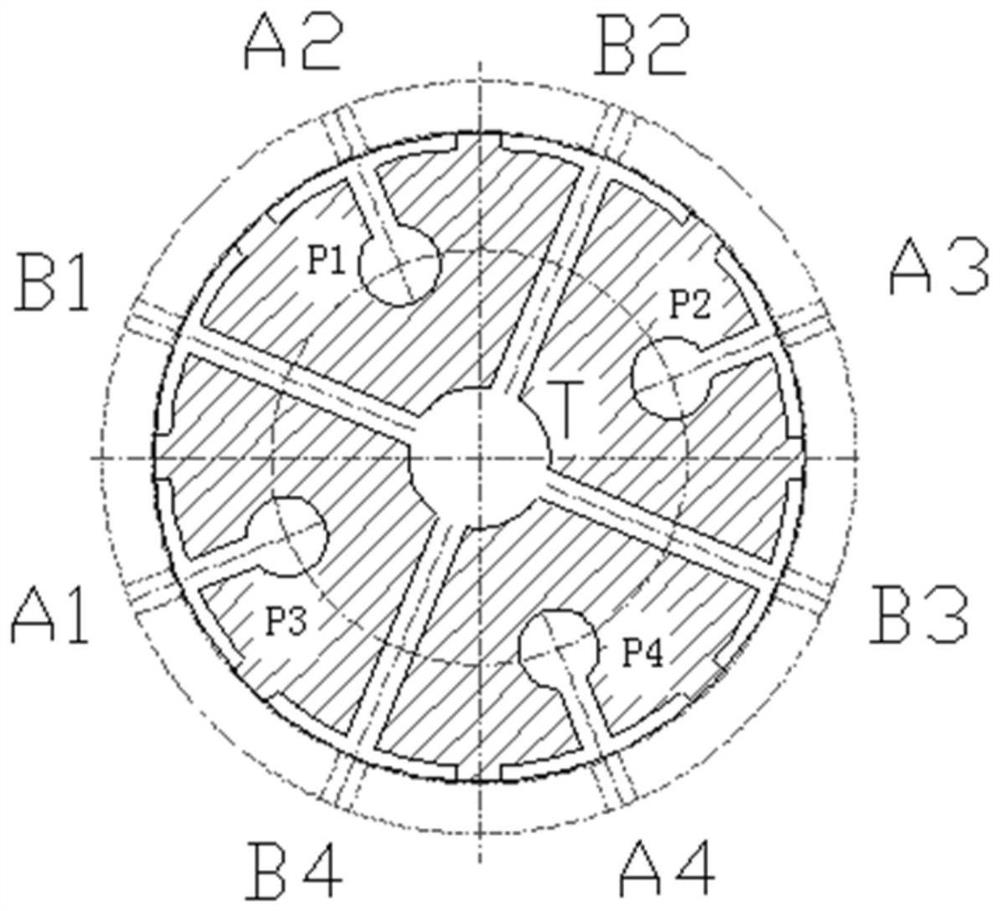

[0031] Such as Figure 1-2 As shown, the present invention provides a synchronous axial flow distribution switch reversing multi-way valve. The axial flow distribution valve 1 is a rotary valve structure, including a shaft flow distribution valve core rotor 2, a sealing ring 3 and a shaft flow distribution valve body stator 4. Adjust the shaft distribution valve core rotor 2 to rotate to different angle ranges to realize the connection / block between the working oil port and the oil supply port P0 and the oil return port T0, and realize the switch control of the action of the actuator;

[0032] Between the axial distribution valve core rotor 2, the four sealing rings 3 and the axial distribution valve body stator 4, three separate sealing areas with different heights are sequentially formed from top to bottom, and the three sealing areas corresponding to the axial distribution valve body stator 4 and The connection relationship of the working oil port of the stator is:

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com