A shaft distribution switch reversing valve

A shaft distribution and reversing valve technology, applied in valve devices, multi-port valves, sliding valves, etc., can solve the problems of restricting the flow capacity, affecting the waterproof level, easy to burn coils, etc., to reduce mechanical contact wear and reduce wear and tear Possibility to achieve the effect of gap sealing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

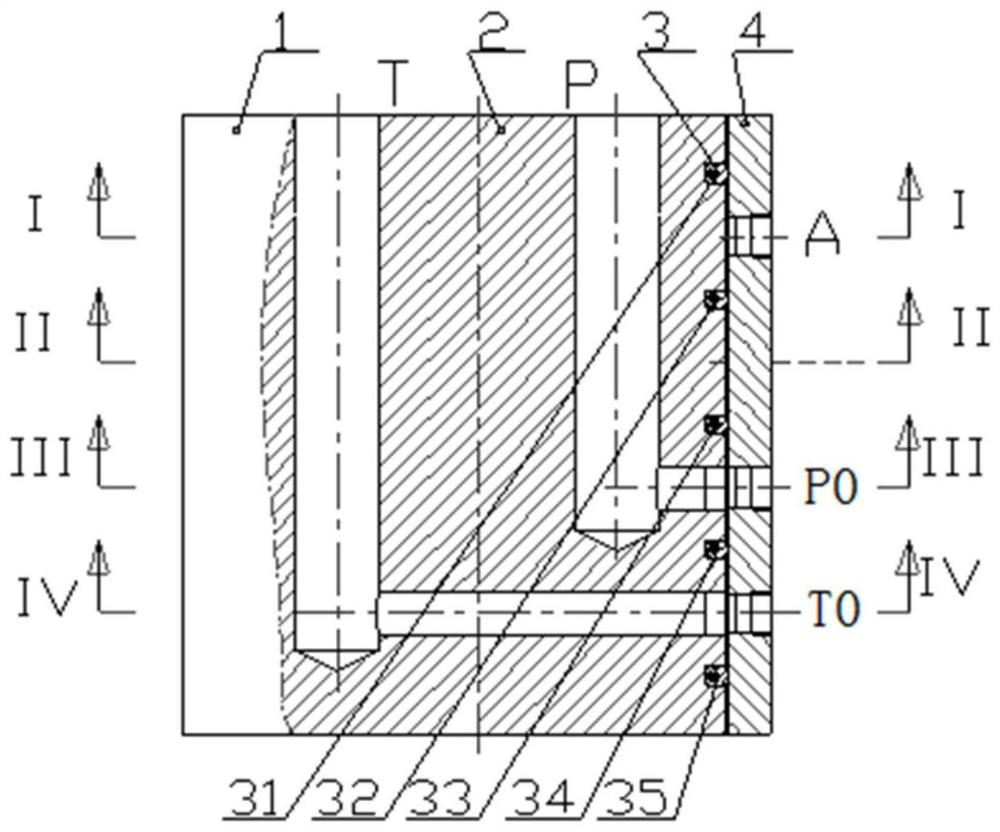

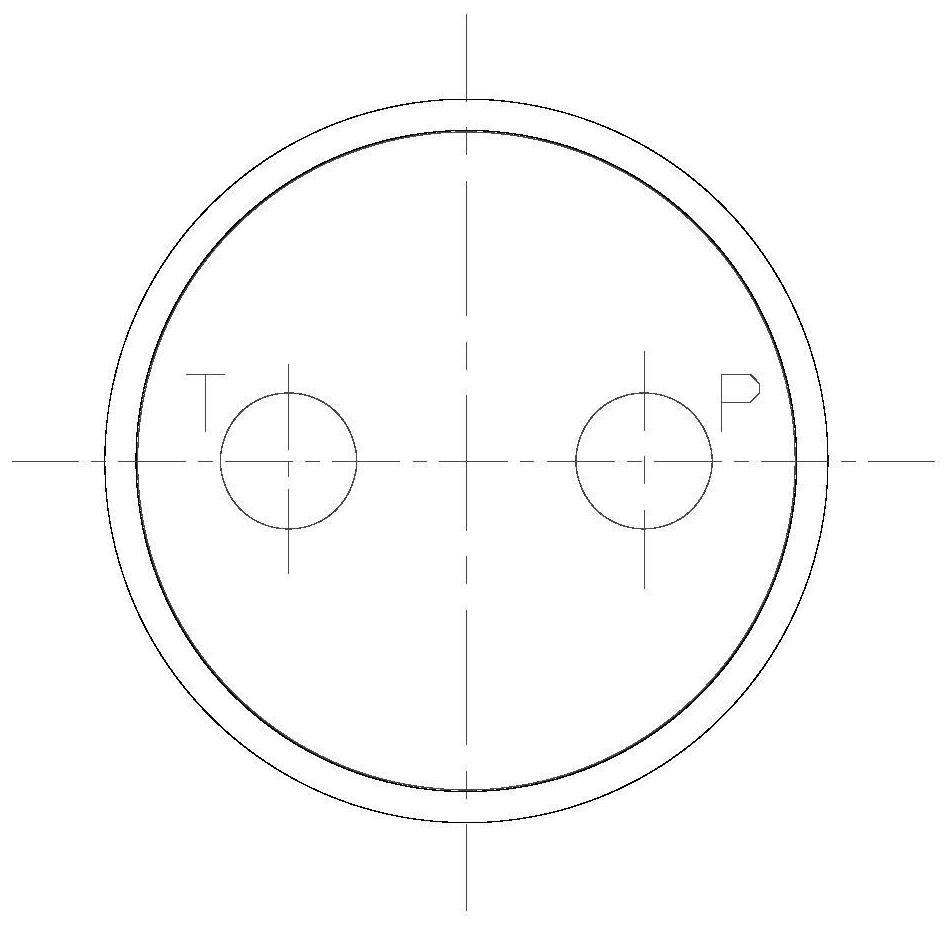

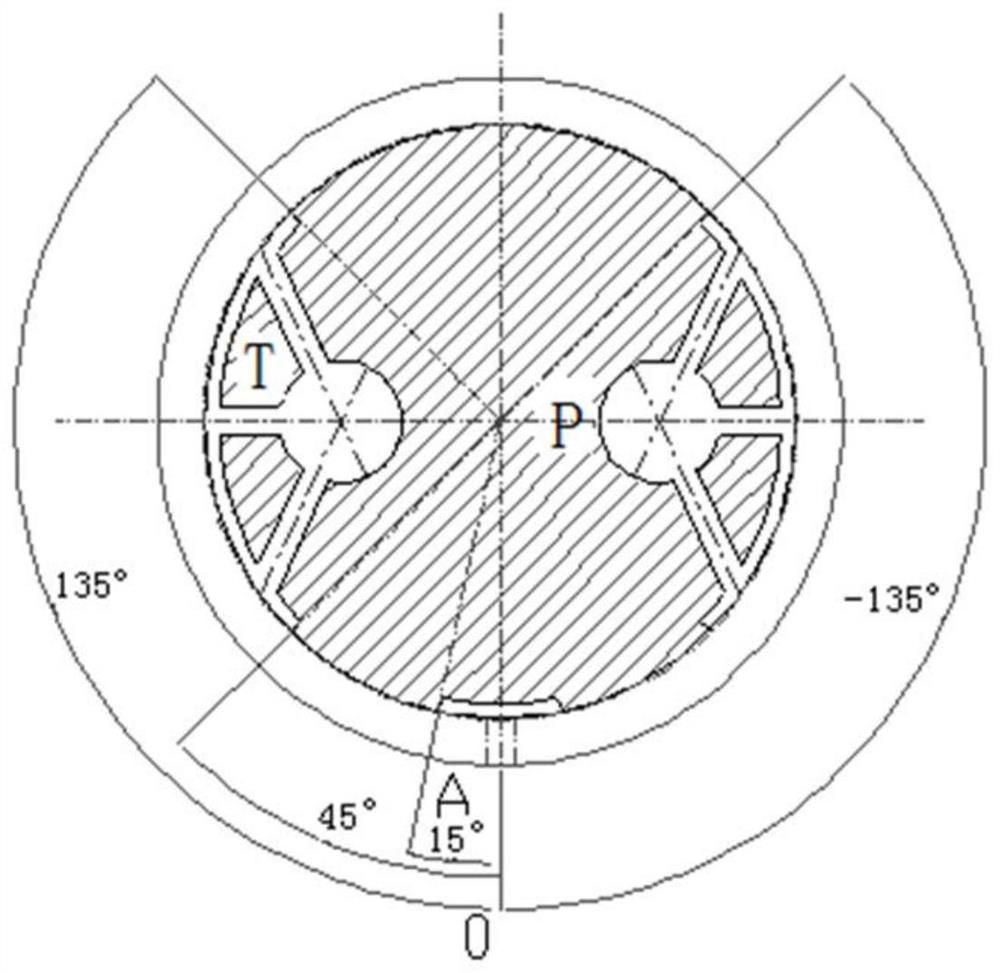

[0037] Such as Figure 1-6 As shown, the present invention provides an axial flow distribution switch reversing valve, which includes an internal axial flow distribution spool rotor 2 and an external axial flow distribution valve body stator 4; by adjusting the rotation of the axial flow distribution spool rotor 2 to different angle ranges, the working The connection / blocking between the oil port and the oil supply port and the oil return port realizes the control of the action of the actuator. It has the advantages of less parts, convenient processing, compact structure, simple, convenient adjustment, large flow capacity, simple maintenance and repeated operation. Advantages of high sex.

[0038] The rotor 2 of the axial distribution valve core and the stator 4 of the axial distribution valve body pass through five sealing rings 3 from top to bottom in the axial direction to form four separated sealing areas that are not connected to each other. The communication relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com