Pipe jacking machine head torsion deviation rectifying devices and deviation rectifying method

A deviation correction device and pipe jacking technology, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipeline laying and maintenance, etc. It can solve problems such as little effect, inability to predict the twisting of the pipe jacking head in advance, and slow twisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more clearly understood, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] Numerous specific details are set forth in the following description to facilitate a full understanding of the present invention, but the present invention may also be implemented in other ways than those described herein, and thus the present invention is not limited by the specific embodiments disclosed below.

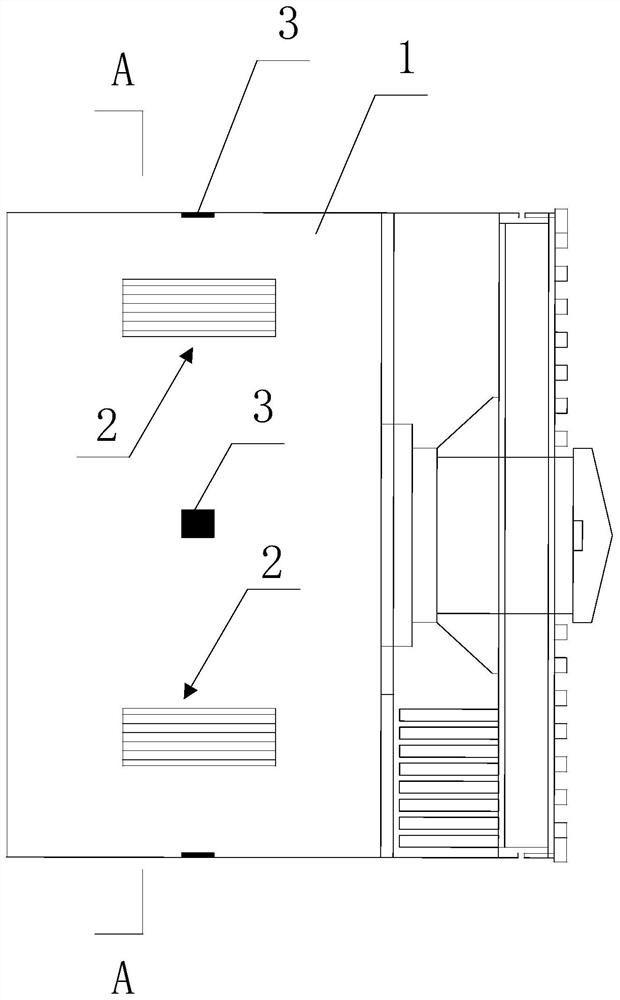

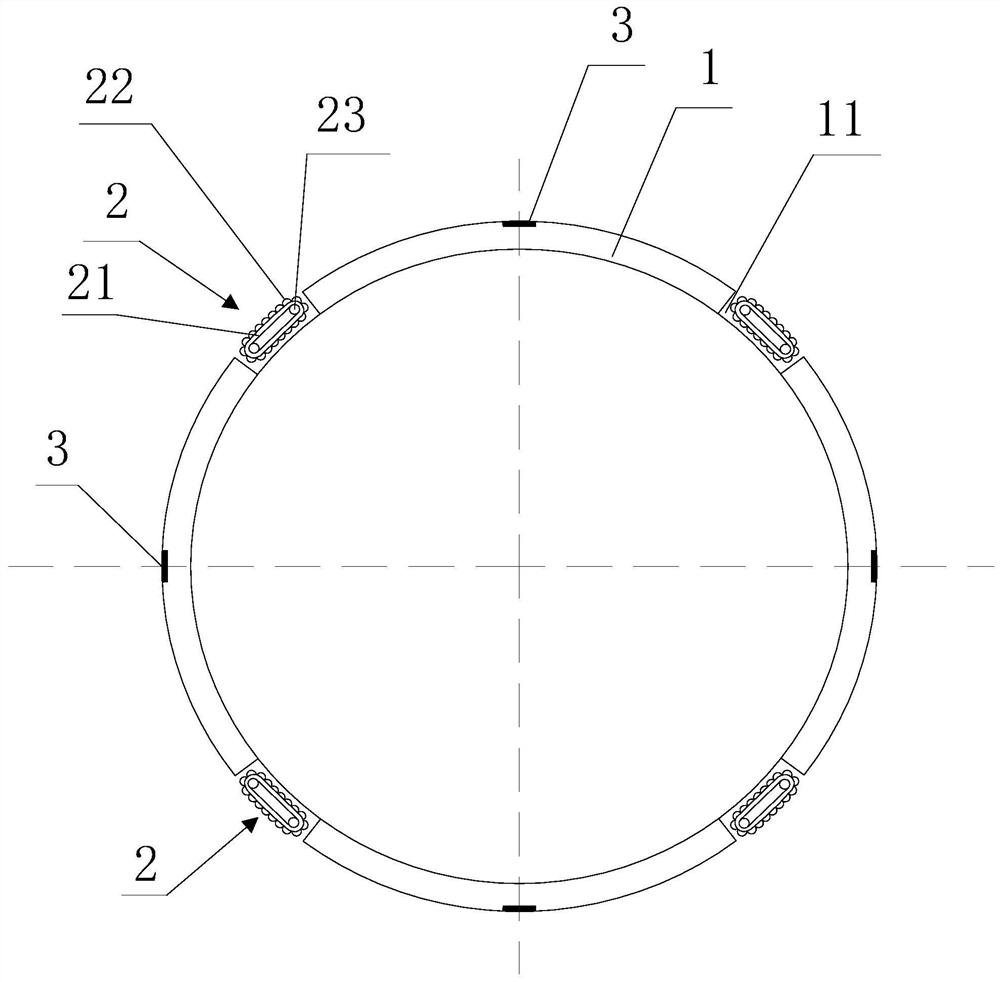

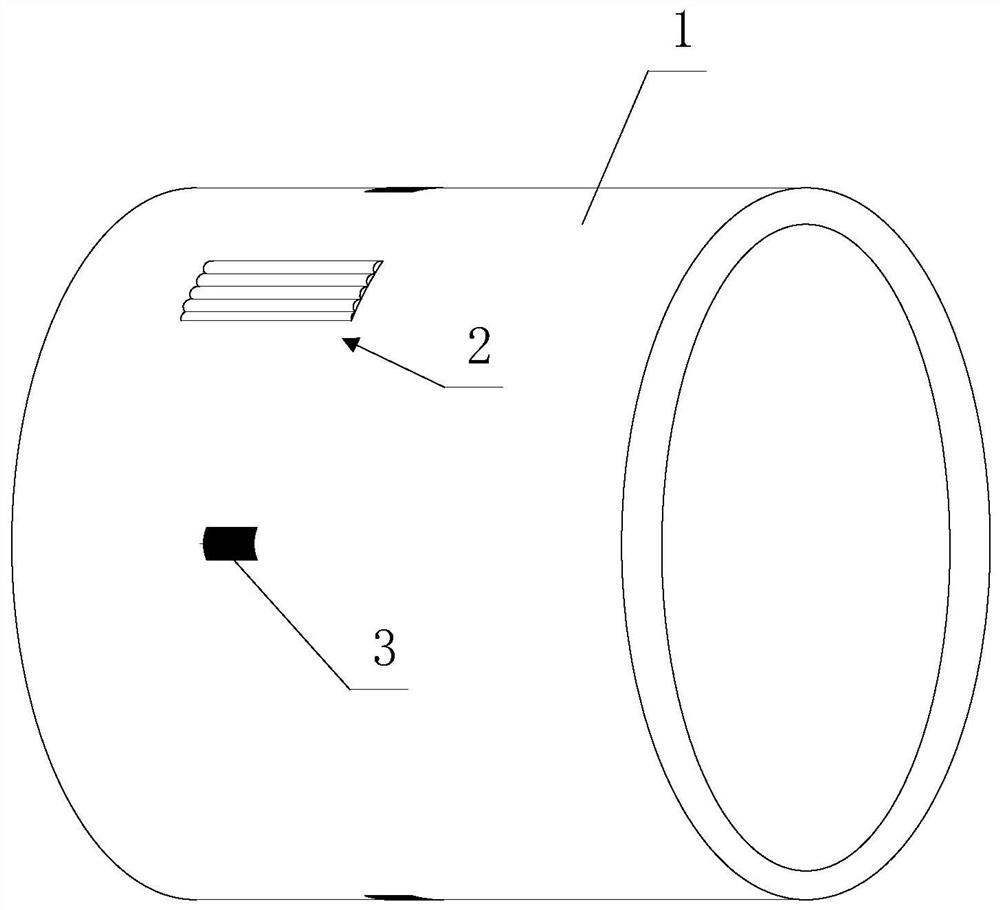

[0034] see Figures 1 to 5 , the embodiment of the present invention provides a pipe jacking head torsion rectification device 2, which is mainly composed of a rectification belt 21, a transmission wheel 23 and a drive motor (not shown in the figure). The torsion rectification device 2 is integrally arranged in the outer wall of the front casing 1 of the pipe jacking head, and the outer side of the torsion rectificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com