Vacuum tube side pressure type exhaust equipment

A technology of exhaust equipment and vacuum tubes, applied in the field of vacuum tubes, can solve problems such as the opening end of the vacuum tube is broken, falling on the top of the air pump, affecting the normal use of the vacuum tube, etc., and achieves the effect of accelerating the pumping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 to attach Figure 5 Shown:

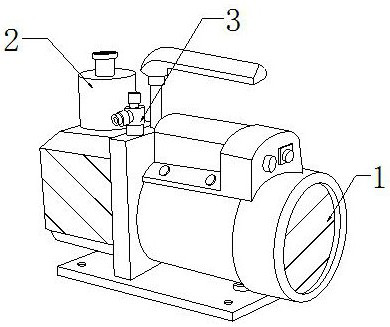

[0030] The present invention provides a vacuum tube side pressure exhaust device, the structure of which includes an air pump 1, a connecting pipe 2, and an exhaust pipe 3, the bottom end of the connecting pipe 2 is vertically fixed on the top of the left end of the air pump 1, and the exhaust pipe 3 Located on the right side of connecting pipe 2.

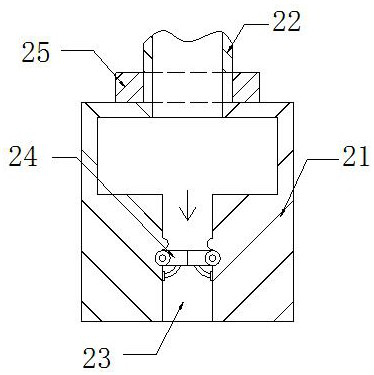

[0031] The connecting pipe 2 includes a pipe body 21, an air inlet pipe 22, an opening 23, an air valve 24, and a buffer mechanism 25. The air inlet pipe 22 is vertically fixed at the top center of the pipe body 21, and the opening 23 runs through the inner center of the pipe body 21. Between the position and the bottom surface, the air valve 24 is installed at the middle and lower position inside the opening 23 , and the buffer mechanism 25 is sleeved outside the bottom end of the intake pipe 22 .

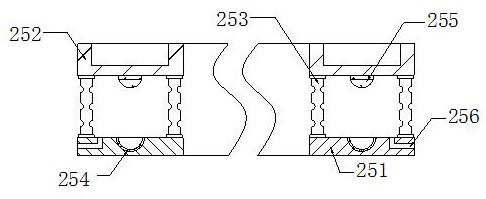

[0032] Wherein, the buffer mechanism 25 includes a support plate 251, a f...

Embodiment 2

[0038] as attached Figure 6 to attach Figure 9 Shown:

[0039] Wherein, the clamping mechanism 52f includes a support plate f1, a clamping plate f2, a push rod f3, and a drainage port f4, the left end of the push rod f3 is fixed on the right side of the support plate f1, and the left side of the clamping plate f2 is It is connected with the right end of the push rod f3, the drainage port f4 runs through between the right side and the upper surface of the support plate f1, and the clamping plate f2 is made of soft rubber material, which is stretchable, which is beneficial for the clamping plate f2 to be received by the opening of the vacuum tube. The different deformation of the outer wall of the end changes, so that the clamping plate f2 is closely attached to the outer wall of the vacuum tube, which can reduce the outside airflow from entering the vacuum tube through the gap between the open end of the vacuum tube and the connecting tube 2 .

[0040] Wherein, the drainage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com