Method for composite flow molding

A molded, actuated technology applied in the direction of coating etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0144] The following terms and its deformation form are defined below for use in the present disclosure and the appended claims:

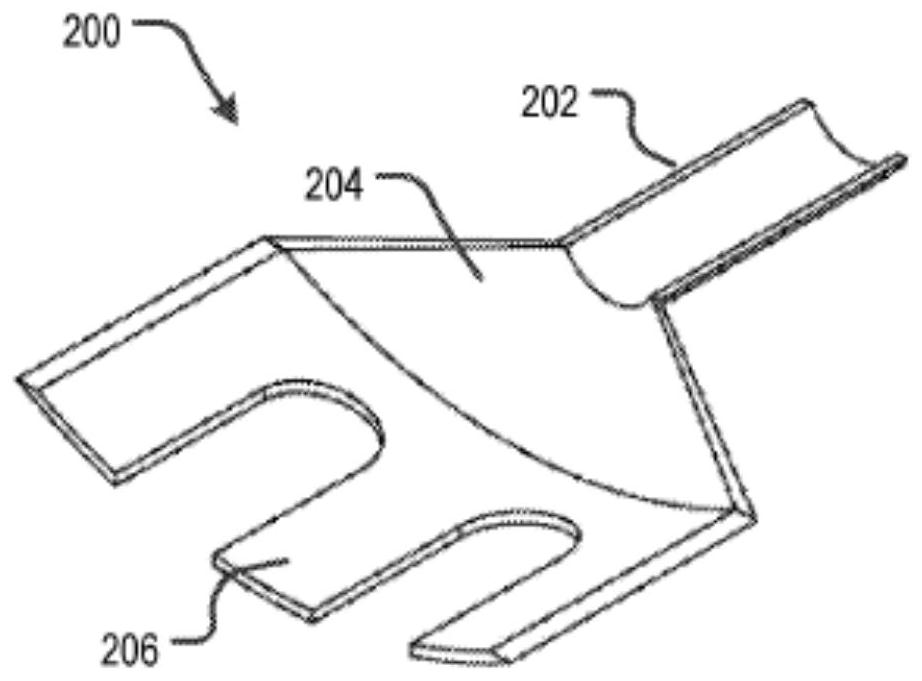

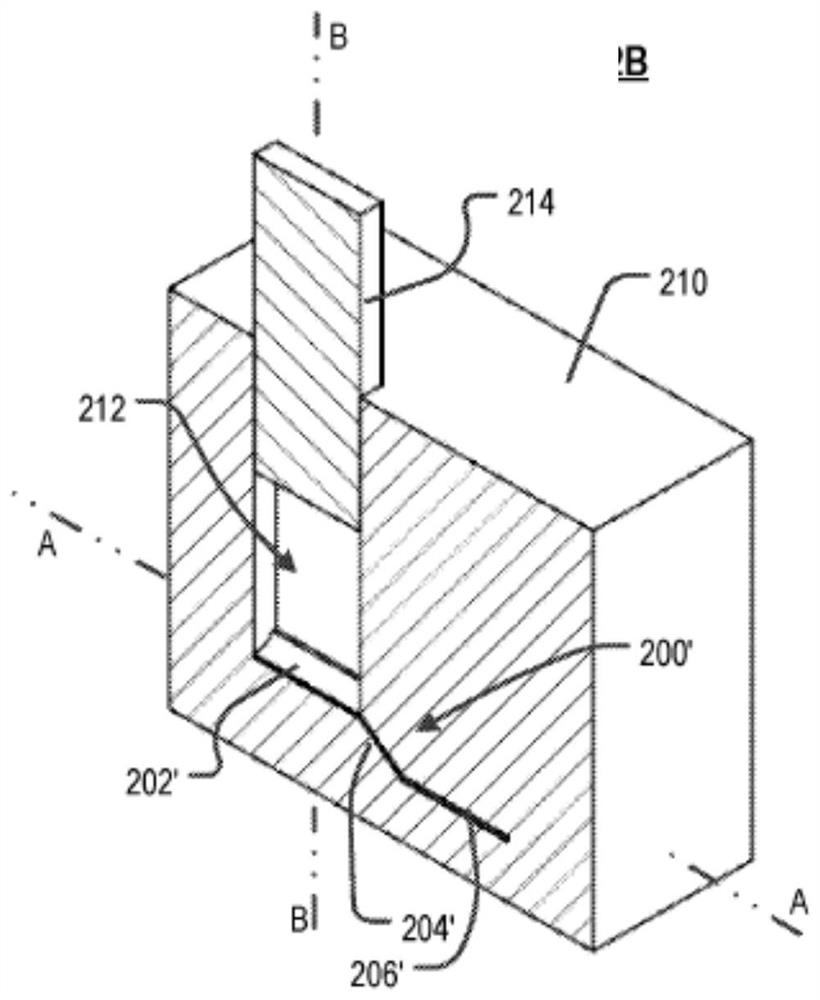

[0145] "Axial or axial alignment" means, for example, in the background of the plunger or plunger chamber, and in the background of the plunger, and in the background of the mold cavity, representing the long (maximum) axis of the mold cavity Or spindle alignment.

[0146] • "Transverse or lateral alignment" means, for example, in the background of the plunger or plunger chamber, in the background of the plunger, and in the background of the mold cavity, with respect to the long in the plane (most Length) The axis of the spin of 90 degrees is aligned.

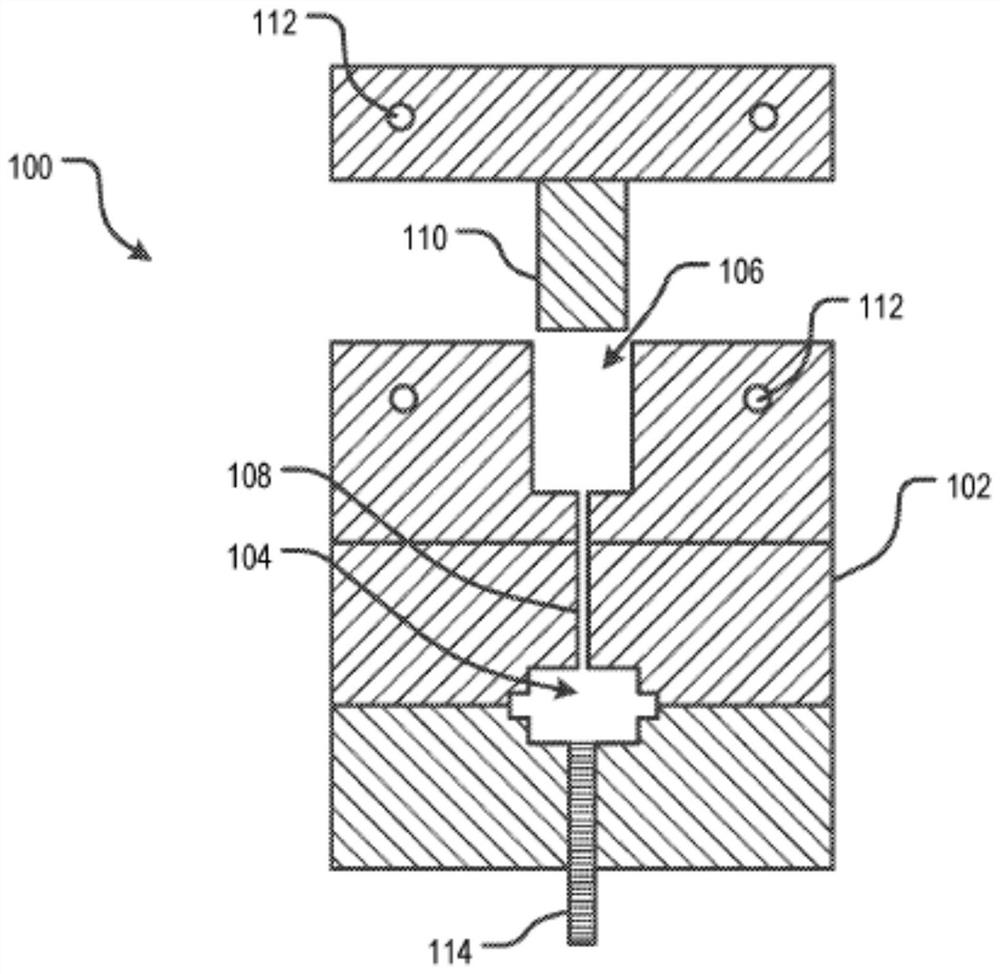

[0147] · "Plane" means, for example, an axis that is rotationally exiting the plane of the plane from the main surface of the mold chamber in the context of the mold cavity. In an embodiment of the invention, the stroke axis of the plunger is outside the plane relative to the main surface of the mold ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com