Automatic plate auxiliary assembly table

A technology for assisting assembly and sheet metal, applied in hand-held tools, manufacturing tools and other directions, it can solve the problems of easy dislocation, eccentricity, low yield, unstable fixing of right-angle pallets, inaccurate positioning, etc., and achieve yield Improve, avoid ectopic, accurate positioning datum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

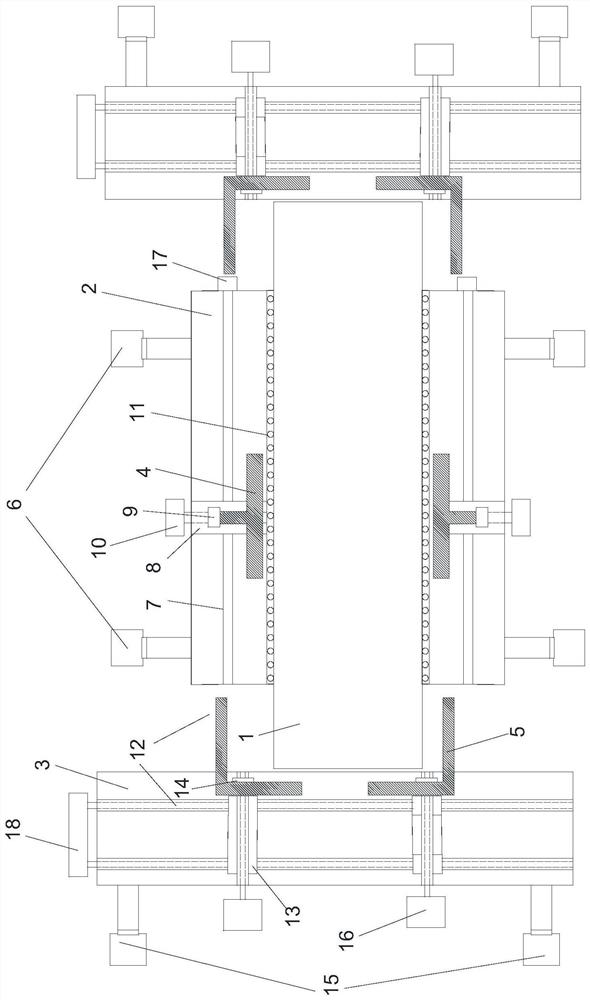

[0044] In the present invention, the automatic plate auxiliary assembly platform includes a first workbench 2, a second workbench 3, a horizontal baffle 4, a right-angle baffle 5, a first workbench adjustment assembly 6, and a second workbench adjustment assembly 15, see figure 1 .

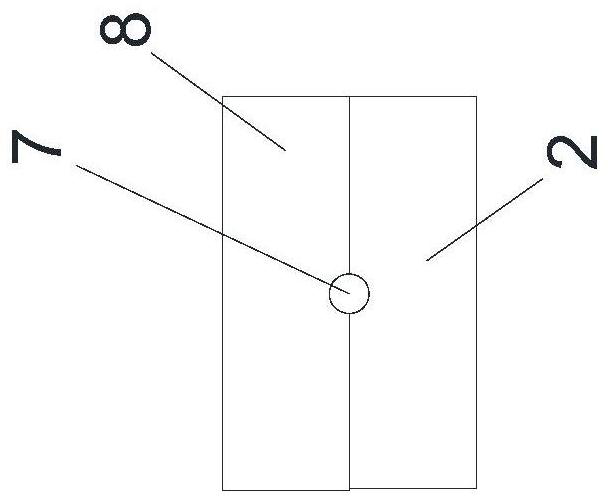

[0045] The first workbench 2 is arranged on both sides of the width direction of the plate 1, and the side of the first workbench 2 close to the plate 1 is provided with a drive wheel 11, and the drive wheel 11 is pressed against the side of the plate 1, and the The rotation of the wheel 11 drives the plate 1 to move horizontally, and the first workbench 2 is provided with a first guide rail assembly. The horizontal baffle 4 is arranged on the first guide rail assembly, and its horizontal plane faces the plate 1. The horizontal baffle 4 can be displaced longitudinally and laterally through the first guide rail assembly.

[0046] The second workbench 3 is located on both sides of the length direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com