An Adjustment Mount That Can Realize Surface Rotation

A technology of adjusting the frame and rotating unit, which is applied in the directions of instruments, measuring devices, workbenches, etc., to reduce structural vibration, reduce measurement costs, and reduce vibration errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the multi-functional design of the adjustment frame enables the clamping of the measured object to be achieved by means of two compression heads, springs and other components when the tested object is clamped by the adjustable frame designed in this patent. On the other hand, the rotation of the front and rear surfaces of the tested part can be realized through the setting of the rotatable round frame in the middle, and the functions of positioning, clamping and vibration reduction can be realized through the design of related components. The adjustment frame of this embodiment solves the defects in the existing measurement methods, especially the clamping and rotation problems of the optical lens during interferometric measurement. The clamping object targeted by the adjustment frame in this embodiment includes an optical lens, and the surface of this kind of lens needs to be measured with high precision so as to accurately reconstruct and evaluate t...

Embodiment 2

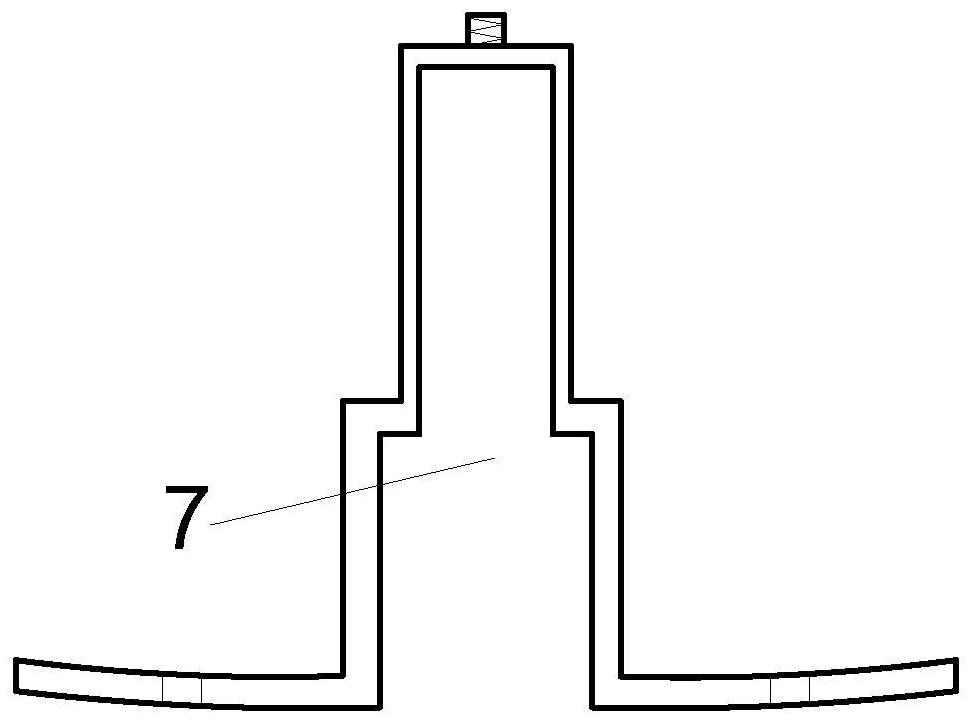

[0041] see Figure 1-Figure 8 , The main part of the adjustment frame that can realize surface rotation includes: upper pressing unit, lower rotating unit, round frame 8, lower rotating rod 15, upper knob 16, square frame 17, upper cover 18, restraint unit, bottom foot unit.

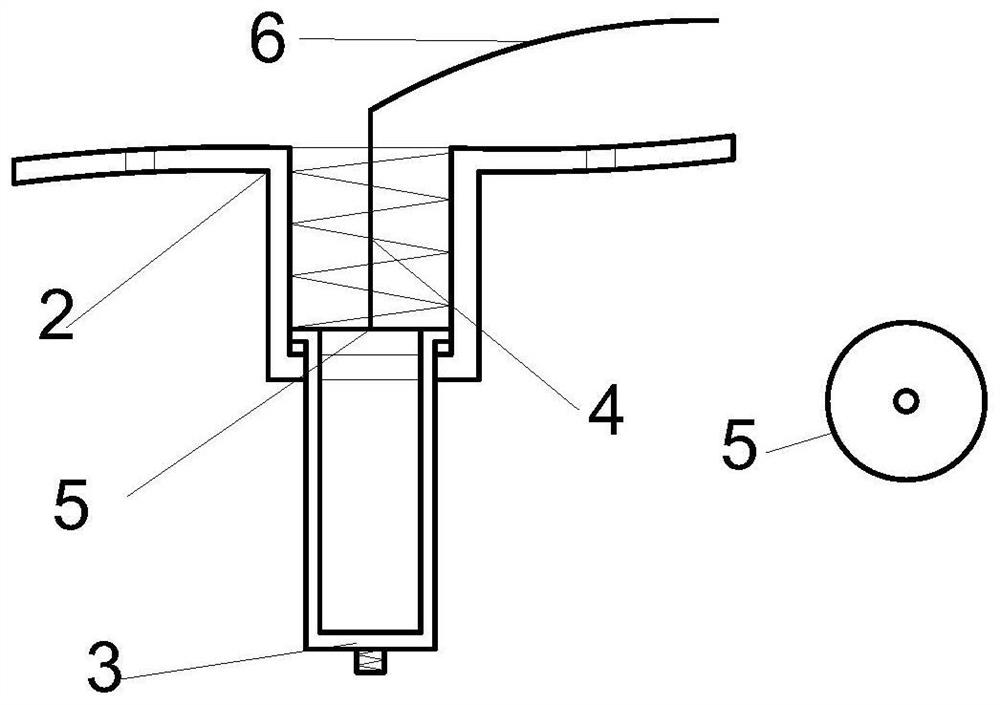

[0042] The upper pressing unit includes: a pressing head 1 , an upper sleeve 2 , a lower sleeve 3 , a sleeve spring 4 , and a pressing piece 5 . Two sets of one type are installed on both sides of the upper part of the round frame 8 respectively, and are riveted through the riveting holes 9 on both sides of the upper casing 2 and the riveting holes 9 on both sides of the upper part of the round frame 8 . The function of the pressing unit is to perform pressing operation on the tested object.

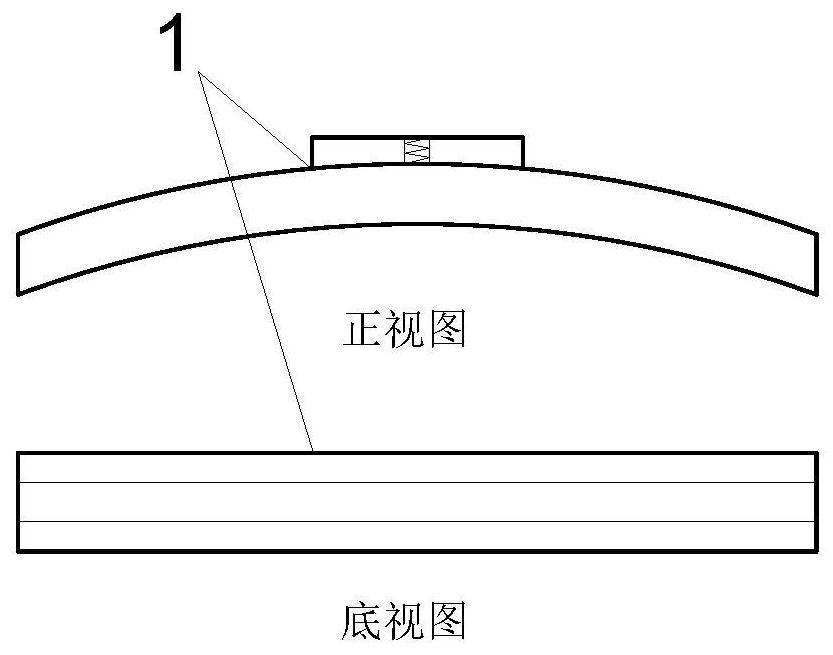

[0043] like figure 1 and figure 2 As shown, one side of the compression head 1 is a cuboid protrusion, and the center of the protrusion is processed with a threaded hole with an internal thread; the other side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com