Graduation certificate batch stamping equipment for educational administration department

A technology of graduation certificates and academic affairs offices, applied in printing, stamping, etc., can solve the problems of slow manual stamping, low stamping efficiency, and small number of diplomas, and achieve high stamping efficiency and clear imprints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

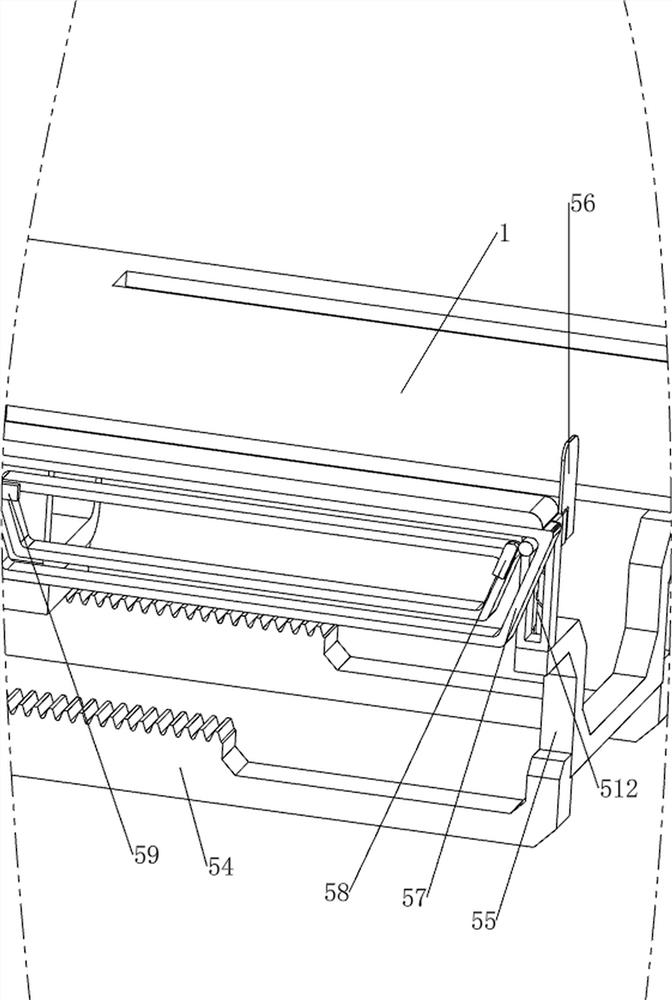

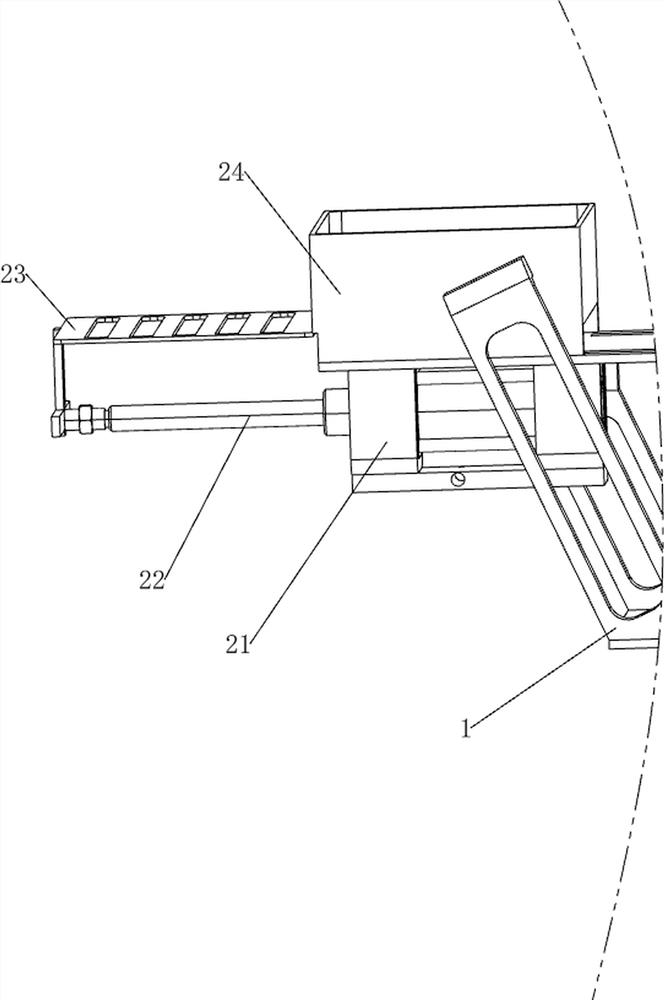

[0072] A batch stamping equipment for graduation certificates used by the Academic Affairs Office, such as figure 1 , figure 2 with image 3As shown, it includes a frame 1, a first pushing mechanism 2 and a stamping mechanism 3, the right side of the frame 1 is provided with the first pushing mechanism 2, and the left side of the first pushing mechanism 2 is provided with the stamping mechanism 3.

[0073] When people need to stamp graduation certificates in batches, this device can be used. First, people place the graduation certificates in the first pushing mechanism 2, then start the first pushing mechanism 2, and the first pushing mechanism 2 The graduation certificate is pushed between the frame 1 and the stamping mechanism 3, and then people manually press the stamping mechanism 3, so that the graduation certificate is stamped, and when the stamping is completed, the first pushing mechanism 2 can be closed.

[0074] The first pushing mechanism 2 includes a fixed mount...

Embodiment 2

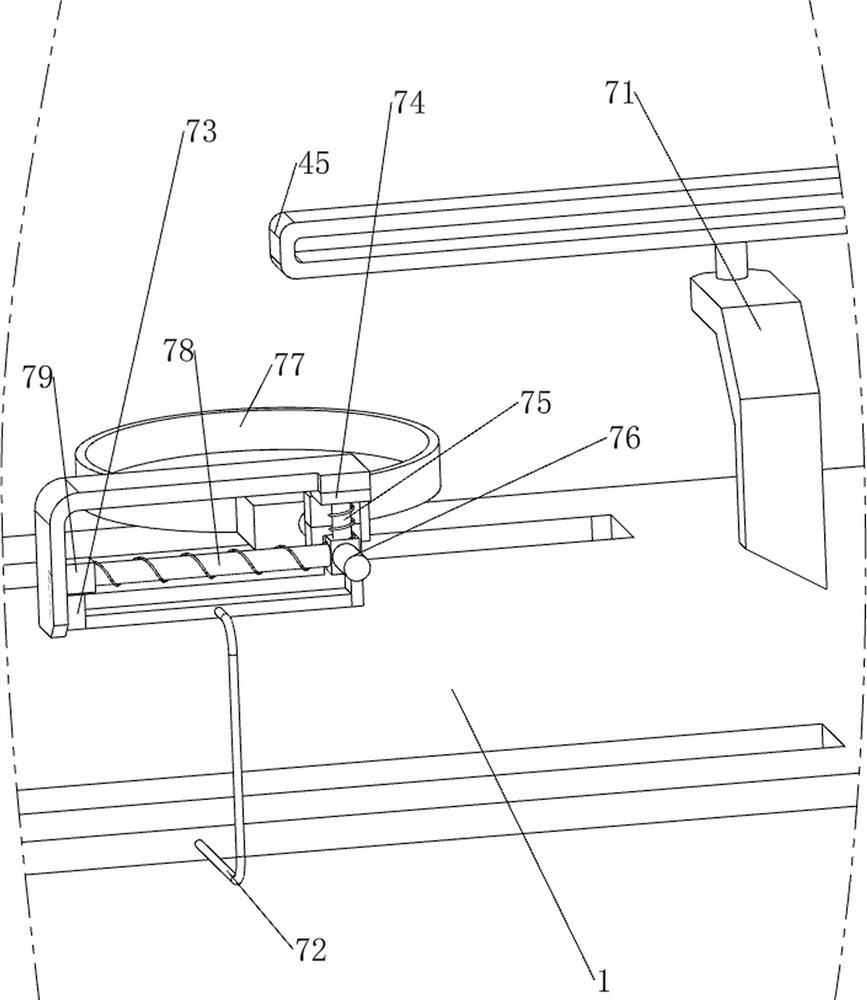

[0079] On the basis of Example 1, such as figure 1 with Figure 4-9 As shown, it also includes an auxiliary mechanism 4, the auxiliary mechanism 4 includes an extension rod 41, a second telescopic assembly 42, a slide rod 43, a connecting rod 44 and a first slide rail 45, and the front side of the fixed rod 31 is provided with an extension rod 41, extending The left side of the rod 41 is provided with a second telescopic assembly 42, and the lower side of the second telescopic assembly 42 is provided with a slide bar 43. The slide bar 43 cooperates with the pressure block 33, and the right part of the front side of the push plate 23 is provided with a connecting rod 44. The connecting rod 44 A first slide rail 45 is provided on the left side, and the slide bar 43 slides on the first slide rail 45 .

[0080] When the push plate 23 moved to the left, the push plate 23 drove the first slide rail 45 to move to the left through the connecting rod 44, and when the slide bar 43 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com