Broken thread detection device of sewing machine

A thread break detection and sewing machine technology, applied in the field of sewing machines, can solve the problems of poor work stability, false alarm, high manufacturing cost, short service life, etc., and achieve the effects of high work efficiency, simple structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

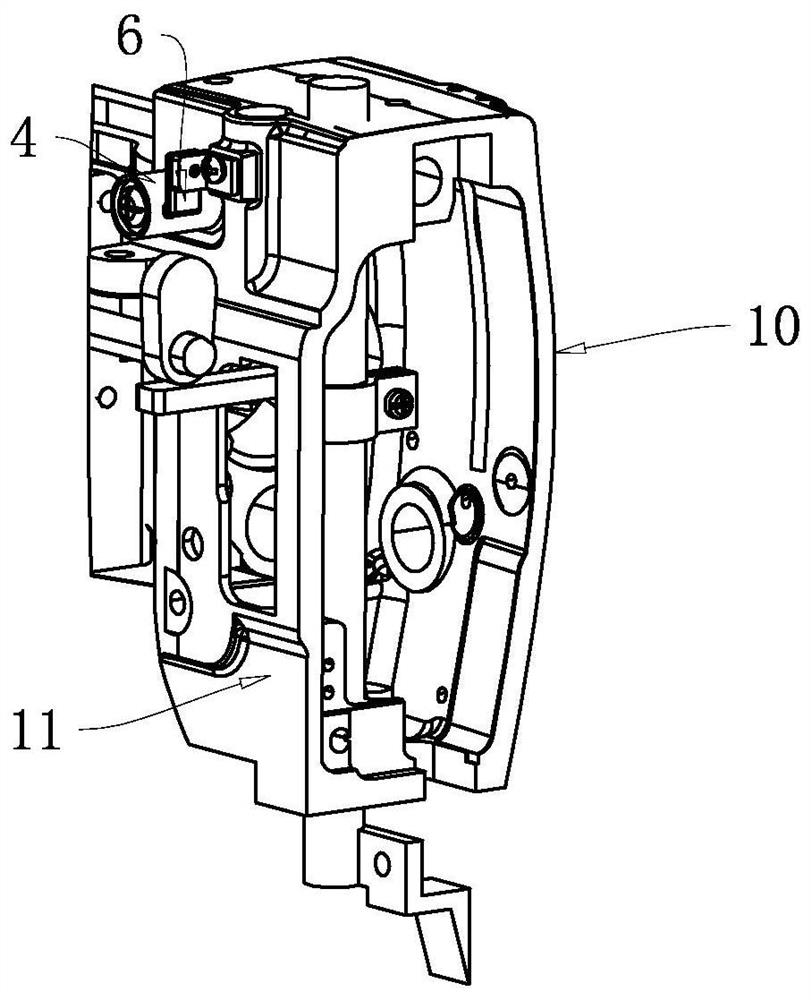

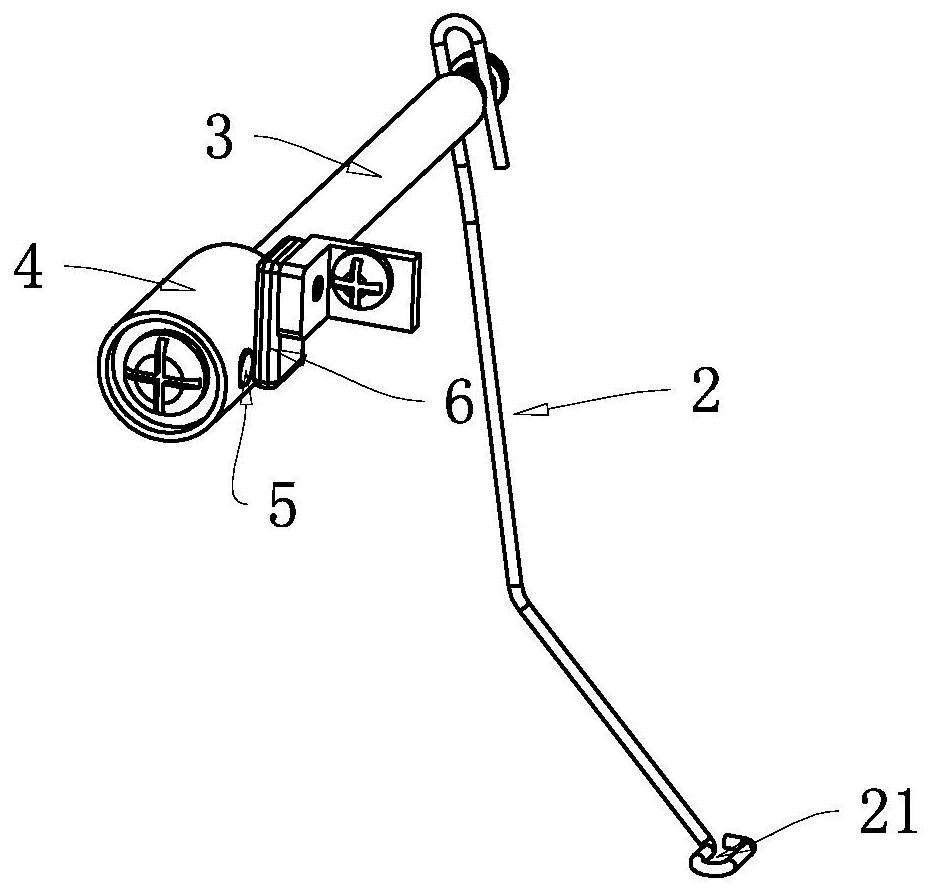

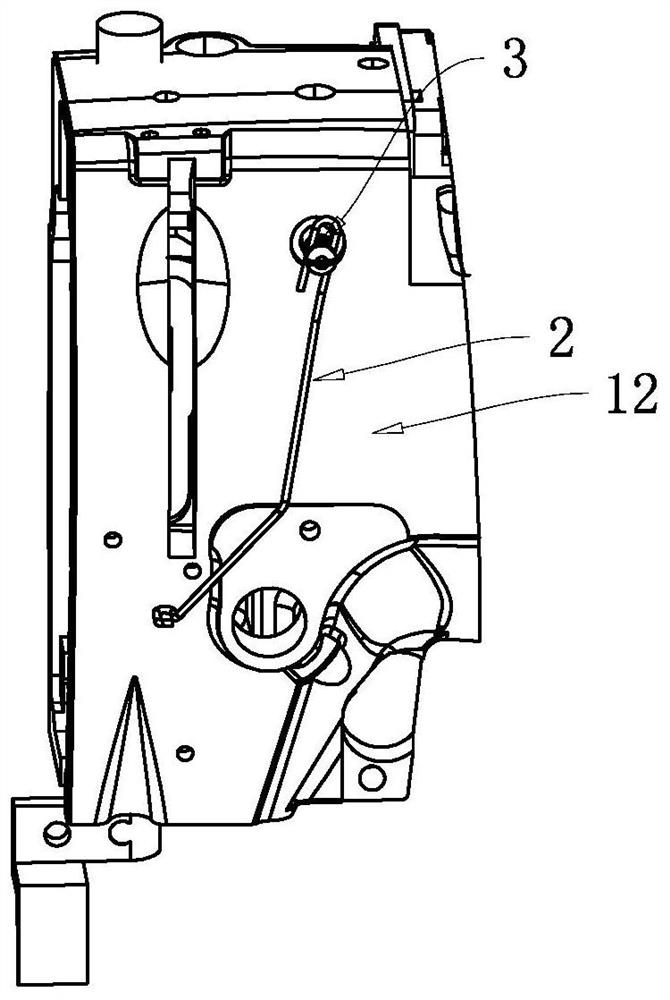

[0017] exist figure 1 figure 2 and image 3 Among them, a thread breakage detection device for a sewing machine in the present application includes a wire rod 2 , a rotating shaft 3 , a magnetic steel fixing base 4 , a magnetic steel 5 and a magnetic sensor 6 . A rotating shaft 3 is sleeved between the back body 11 and the front body 12 of the sewing machine body 10, the rotating shaft 3 can rotate between the back body 11 and the front body 12, and the front body 12 side of the rotating shaft 3 is fixedly connected with a wire rod 2, The back body 11 side of the rotating shaft 3 is installed and connected with a magnetic steel fixing seat 4, and a magnetic steel 5 is fixed on the magnetic steel fixing seat 4, and a magnetic sensitive sensor 6 is installed on the back body 11 corresponding to the magnetic steel 5, and the magnetic steel 5 is used. In the induction magnetic sensor 6.

[0018] Above-mentioned threading lever 2 is fixed on the rotating shaft 3 with screw fixi...

Embodiment 2

[0022] exist Figure 4 Among them, the second embodiment is basically the same as the first embodiment, except that the above-mentioned magnetic steel fixing seat 4 and magnetic sensor 6 are installed on the front body 12, and there is no rotating shaft 3 between the back body 11 and the front body 12. , The magnetic steel fixed seat 4 is sleeved on the front body 12 and can rotate, and the magnetic steel fixed seat 4 rotates with the rotation of the wire rod 2 equally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com