A vibration damping fastener system

A technology of damping fasteners and damping pads, applied in the directions of roads, buildings, tracks, etc., can solve the problems of unfavorable line adjustment, high installation height, poor stability, etc., to offset the trend of lateral deformation, avoid lateral deformation, and ensure reduced The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

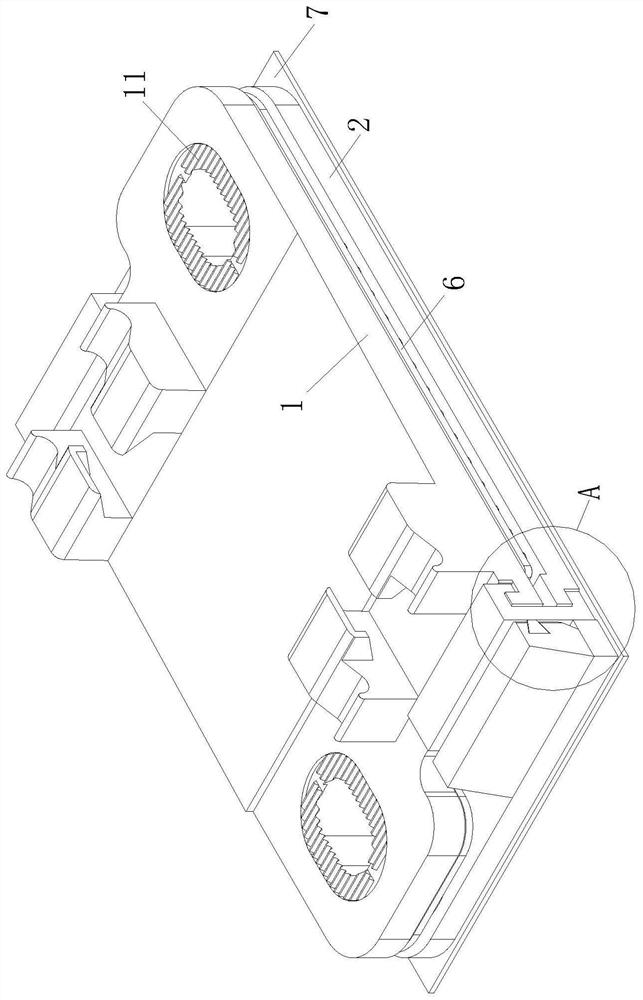

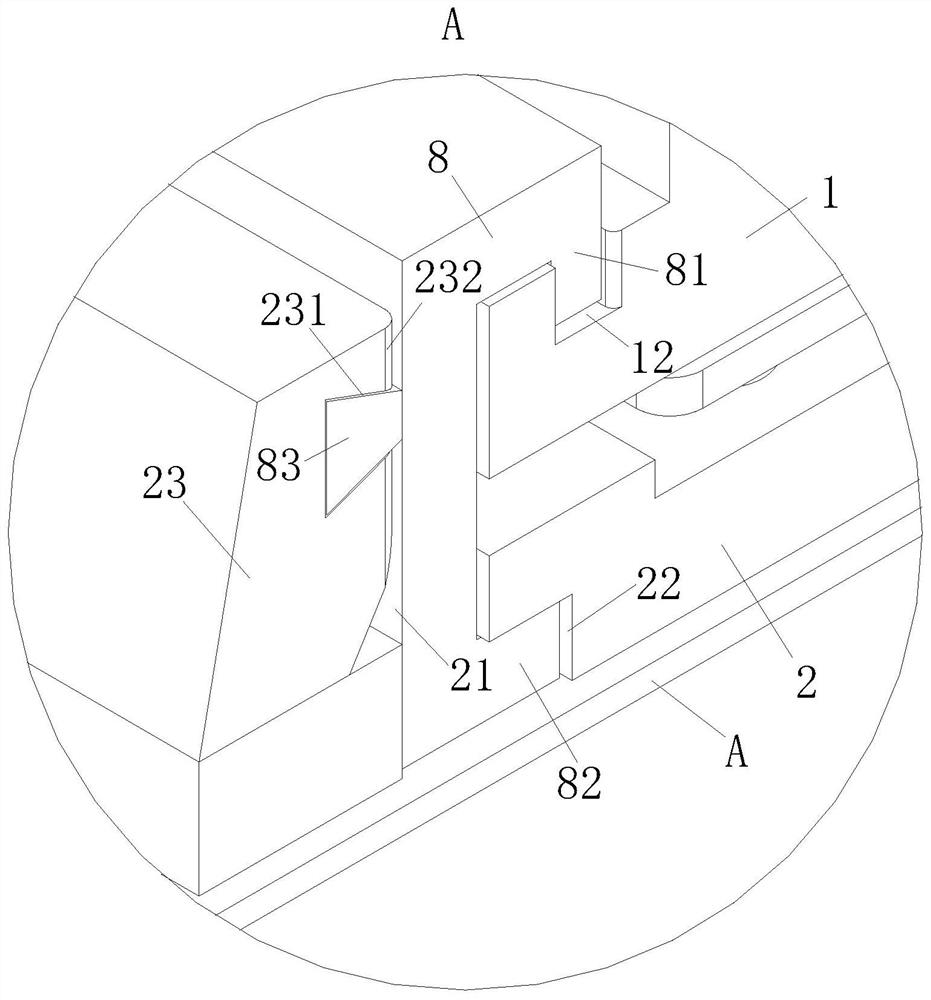

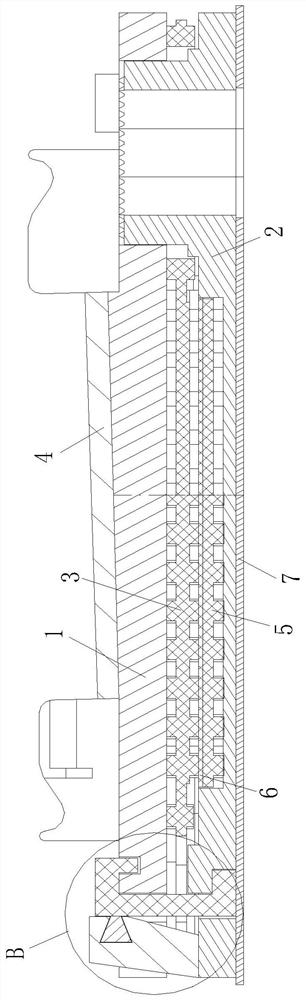

[0030] As an embodiment of the present invention, the parts on both sides of the lower bottom plate 2 close to the installation groove 21 protrude upwards, and form a limiting shoulder 23; Close contact with the side away from the upper iron backing plate 1.

[0031] When working, the limit stop shoulder 23 on the lower base plate 2 plays a lateral limit effect on the self-locking buckle 8 in the installation groove 21, which enhances the lateral rigidity of the fastener system. When the train passes and makes the fastener system vibrate , the self-locking buckle 8 has a deformation tendency to both sides under the vibration of the parts in contact, and the end of the limit shoulder 23 plays a supporting role on the self-locking buckle 8, so that the lateral deformation trend of the self-locking buckle 8 is effectively controlled Offset to avoid lateral deformation of the self-locking buckle 8, thereby affecting the fixation of the self-locking buckle 8 to the fastener system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com