Centrifugal blower

A centrifugal and blower technology, which is applied in mechanical equipment, engine manufacturing, non-variable pumps, etc., can solve the problem of increased filter pressure loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

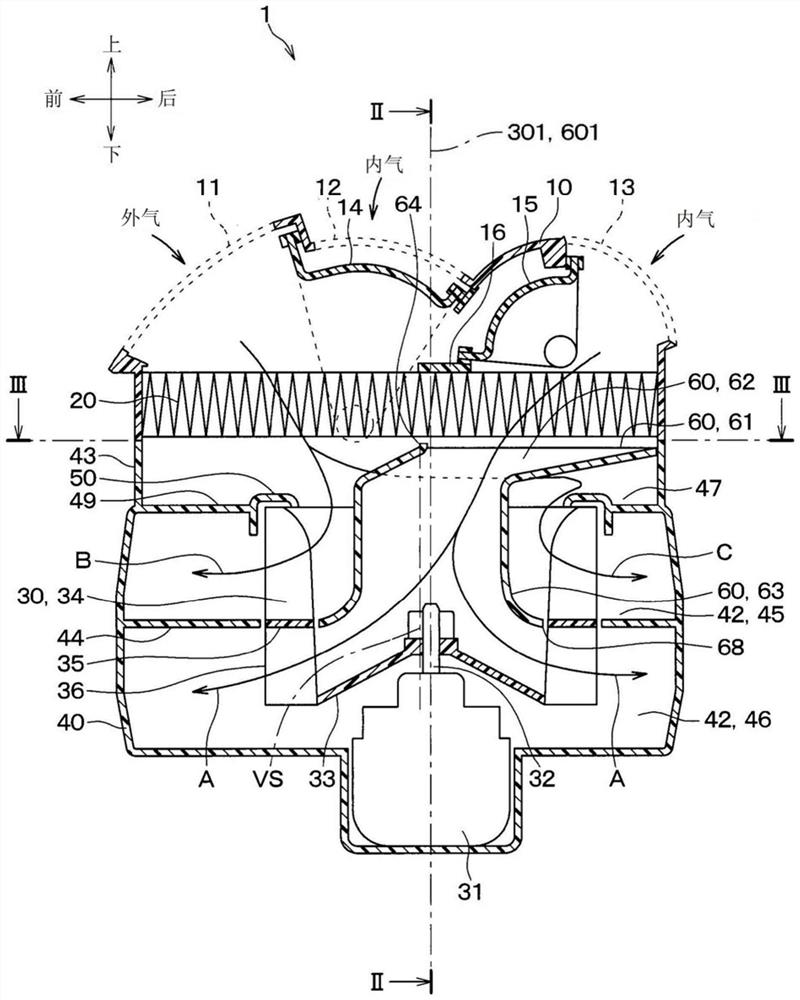

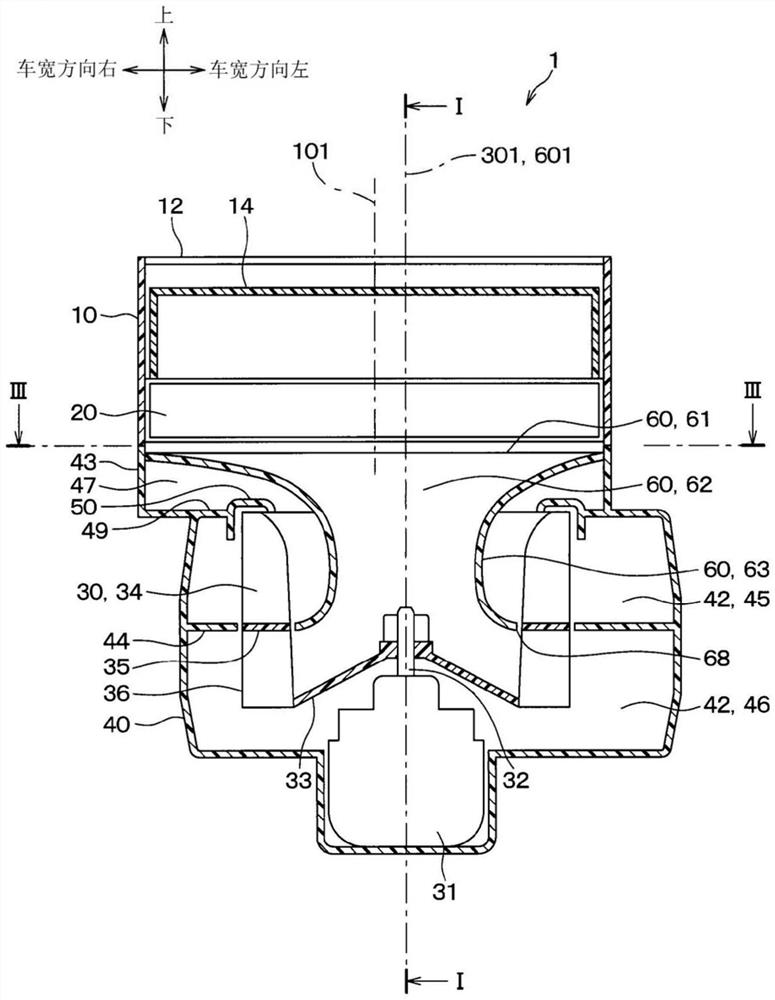

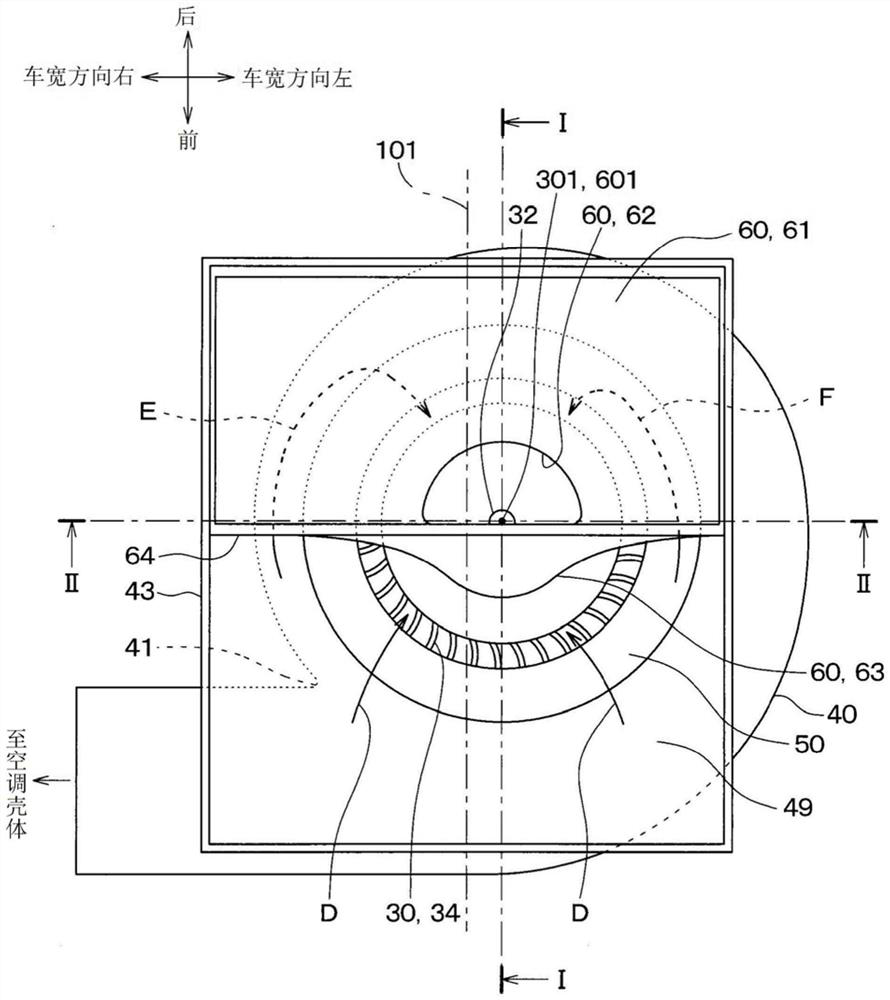

[0044] A first embodiment will be described with reference to the drawings. The centrifugal blower 1 of the present embodiment is suitable for a vehicle air conditioner of a double-flow type of internal and external air. This centrifugal blower 1 is a blower capable of distinguishing between vehicle interior air (hereinafter referred to as internal air) and vehicle outdoor air (hereinafter referred to as external air), sucking them in and blowing them out simultaneously.

[0045] Such as Figure 1 ~ Figure 4 As shown, the centrifugal blower 1 includes an inner and outer air box 10 , a filter 20 , an impeller 30 , a scroll case 40 , a bell mouth 50 , a partition wall 44 , a separation cylinder 60 , and the like.

[0046]The inner and outer air boxes 10 are disposed on the upper part of the centrifugal blower 1 . The inner and outer air box 10 has an outside air inlet 11 , a first inside air inlet 12 , and a second inside air inlet 13 in order from the vehicle front side. The...

no. 2 approach

[0074] Such as Image 6 and Figure 7 As shown, in the second embodiment, the air introduction plate 61 of the separation cylinder 60 has: the first surface 65 located on the first opening 71 side, the second surface 66 located on the second opening 72 side, and the The stepped surface 67 connecting the first surface 65 and the second surface 66 . The second face 66 is disposed closer to the bell mouth 50 than the first face 65 is. In addition, in the second embodiment, the center 101 of the inner and outer air tank 10 is also located at a position deviated to the first opening 71 side with respect to the rotation shaft 301 of the impeller 30 and the central axis 601 of the cylindrical portion 63 included in the separation cylinder 60 . Location.

[0075] According to the above configuration, in the second embodiment, the cross-sectional area of the flow path of the region of the first opening 71 on the side closer to the air introduction plate 61 than the impeller 30 is ...

no. 3 approach

[0077] Such as Figure 8 and Figure 9 As shown, in the third embodiment, the air introduction plate 61 included in the separation cylinder 60 is positioned relative to the bell mouth in such a manner that the portion on the second opening 72 side is closer to the bell mouth 50 than the portion on the first opening 71 side. 50 tilt. In addition, in the third embodiment, the center 101 of the inner and outer air tanks 10 is also located at a position deviated from the rotation shaft 301 of the impeller 30 and the central axis 601 of the cylindrical portion 63 of the separation cylinder 60 toward the first opening 71 side. Location.

[0078] According to the above configuration, in the third embodiment, the cross-sectional area of the flow path of the region of the first opening 71 on the side closer to the air introduction plate 61 than the impeller 30 is larger than that of the second opening 72 compared to the impeller 30 . The cross-sectional area of the flow path in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com