Material surface grinding equipment for high-end equipment manufacturing

A technology for equipment manufacturing and material, applied in the field of material surface grinding equipment, it can solve the problems of manpower consumption, random movement of materials, and inability to accurately position the material, and achieve the effect of improving grinding efficiency, saving labor, and easily limiting the original placement position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

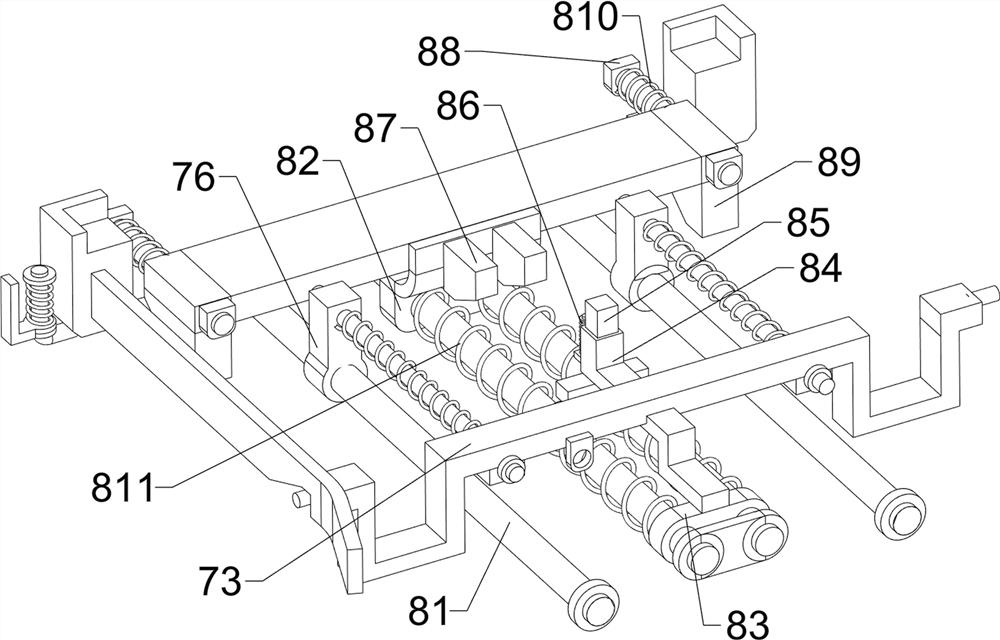

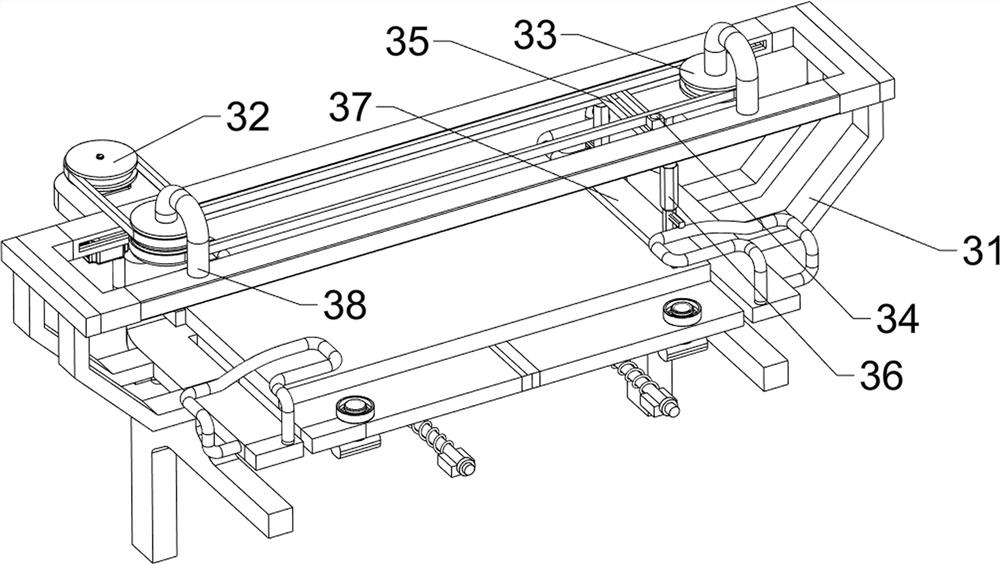

[0030] A material surface grinding equipment for high-end equipment manufacturing, such as figure 1 , figure 2 and image 3 As shown, it includes a workbench 1, a motor 2, a grinding mechanism 3 and a positioning mechanism 4, the upper left side of the workbench 1 is provided with a grinding mechanism 3, the front side of the left part of the grinding mechanism 3 is provided with a motor 2, and the left side of the workbench 1 is provided with a There is a positioning mechanism4.

[0031] The grinding mechanism 3 includes a first mounting frame 31, a first transmission assembly 32, a second transmission assembly 33, a connecting rod 34, a first sliding frame 35, a telescopic rod 36, a grinding block 37 and a support column 38, and the upper left side of the workbench 1 The first mounting frame 31 is connected to the side, and the motor 2 is installed on the left front side of the first mounting frame 31. The front and rear symmetrical support columns 38 are connected to the...

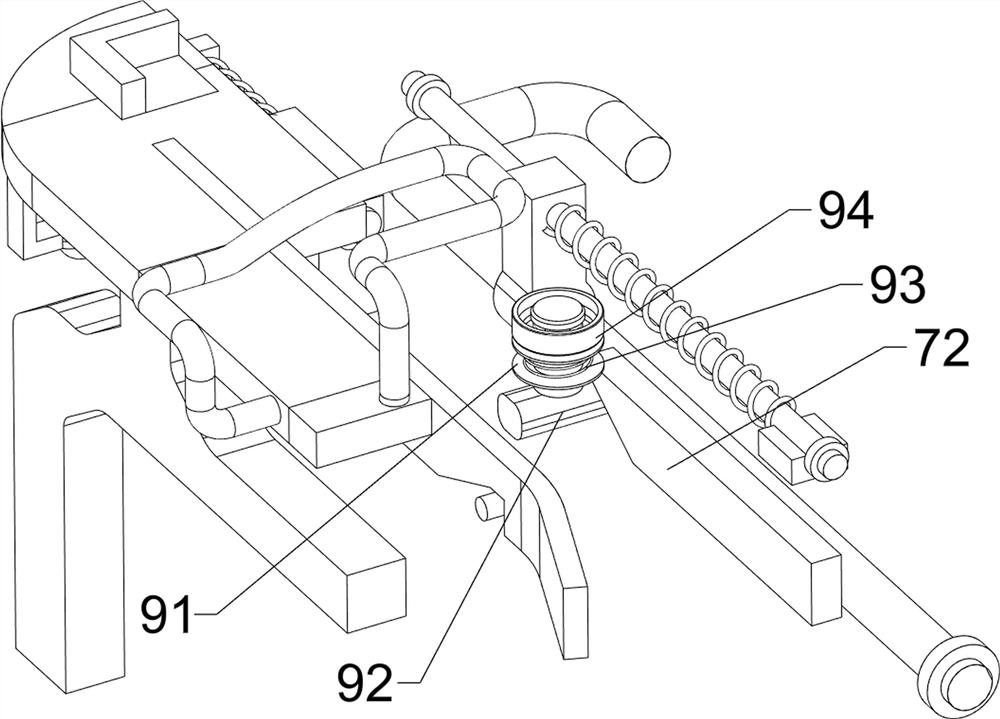

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a lifting mechanism 5 is also included, and the lifting mechanism 5 includes a guide frame 51, a first guide rod 52, a second spring 53 and a stop rod 54, and the left and right sides of the upper side of the workbench 1 are symmetrically connected with guides. Frame 51, the first guide rod 52 is connected with the inner lower side of the telescopic rod 36, and the first guide rod 52 is connected with a stop rod 54 in a sliding manner. A second spring 53 is connected between them, and the second spring 53 is sleeved on the first guide rod 52 .

[0036] In the starting state, the telescopic rod 36 moves forward from the rear side, driving the stop rod 54 to move forward, and after the lower side of the stop rod 54 touches the rear guide frame 51, it is pushed to move upward, thereby compressing the telescopic rod 36 and driving the grinding block 37 moves upwards,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com