Glass forming mold, glass forming device and forming method

A technology of glass forming and mould, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc. It can solve the problems of hard to remove marks, high cost and low efficiency of manufacturing process, so as to avoid oxidation and powder removal and reduce various Morphological defects, the effect of simplifying the polishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

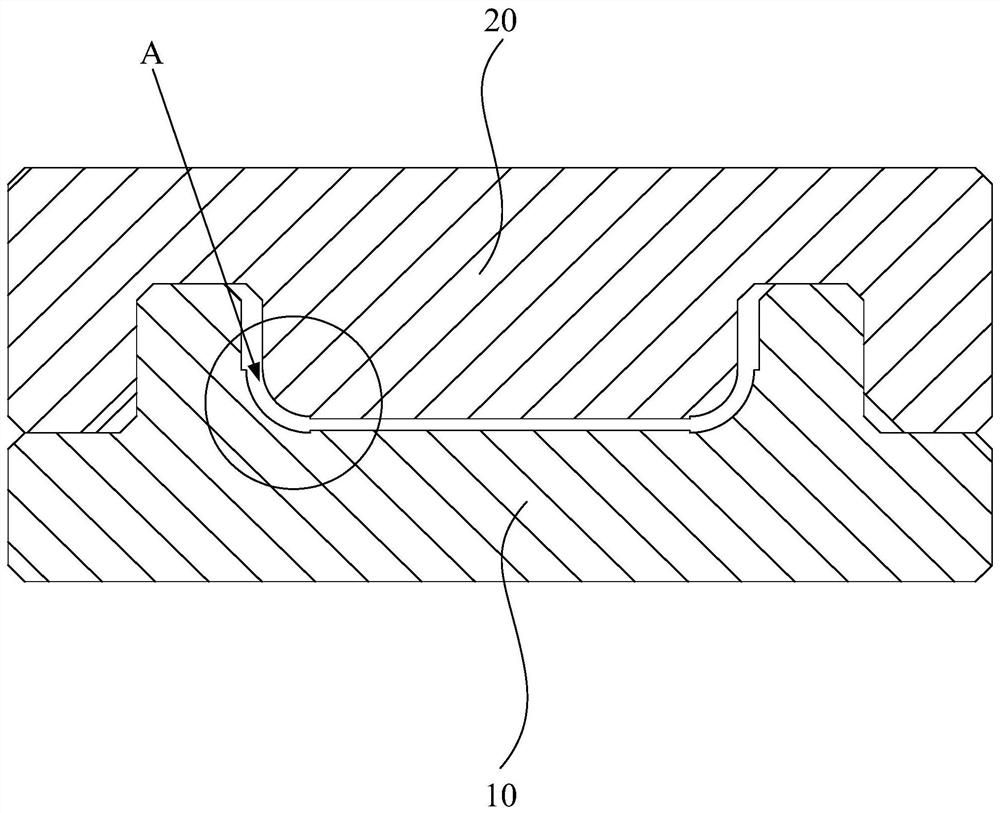

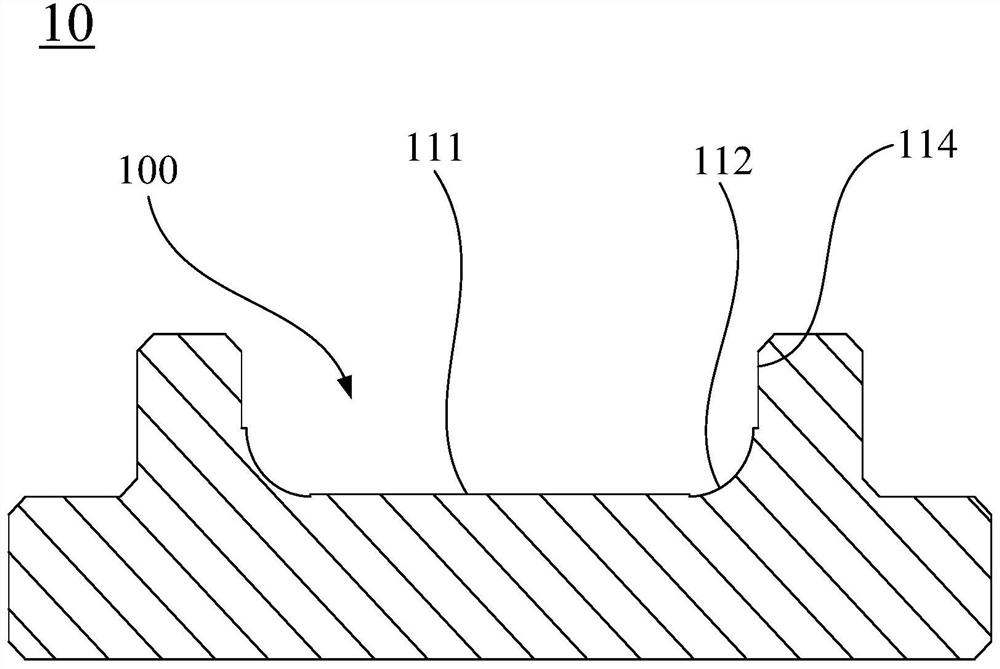

[0070] A glass forming mold includes a setting mold and a pressing mold used in conjunction.

[0071] The shaping mold is provided with a shaping groove, and the bottom of the shaping groove is provided with a groove bottom plane area and a groove bottom curved surface area;

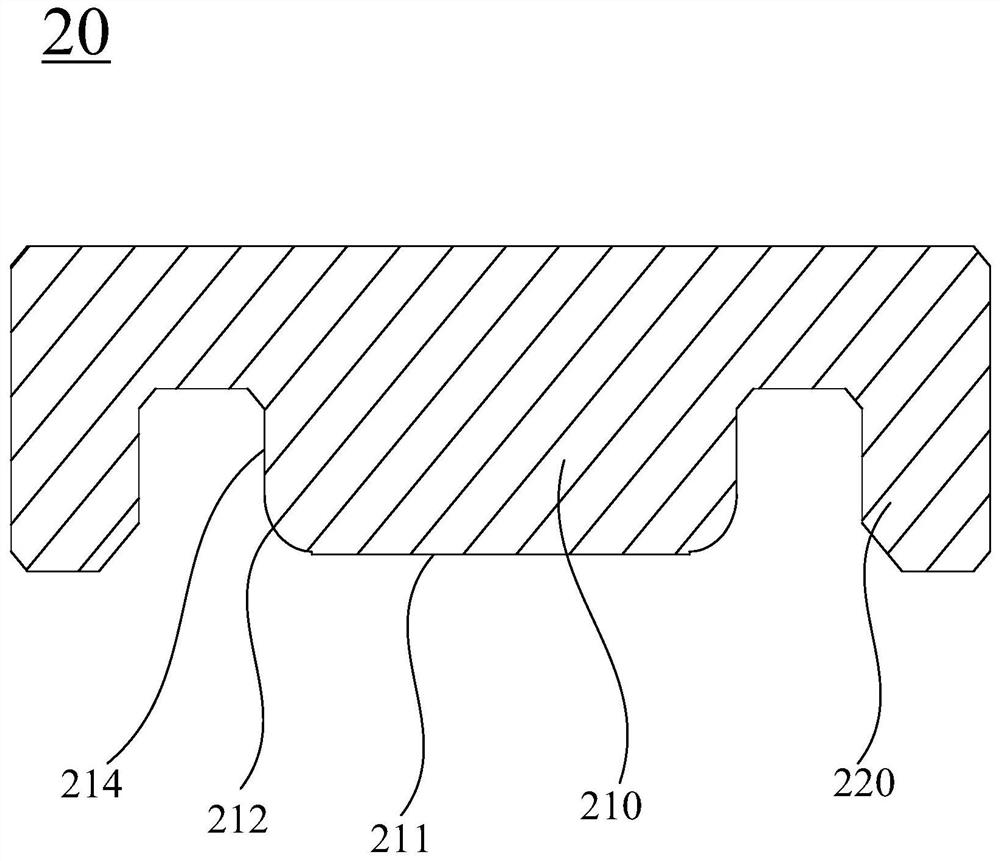

[0072] The pressing mold is provided with a shaping bump, and the top of the shaping bump is provided with a bump plane area and a bump surface area, and the bump plane area is compatible with the groove bottom plane area, and the bump curve area is compatible with the groove bottom curved surface area match.

[0073] The distance between the flat area of the groove bottom and the flat area of the protrusion is 0.58mm, and the distance between the curved surface area of the groove bottom and the curved surface of the protrusion is 0.64mm. The groove bottom planar area is connected to the groove bottom curved surface area through a step with a depth of 0.03 mm, and the bump flat area is connected t...

Embodiment 2

[0075] A glass forming mold includes a setting mold and a pressing mold used in conjunction.

[0076] The shaping mold is provided with a shaping groove, and the bottom of the shaping groove is provided with a groove bottom plane area and a groove bottom curved surface area;

[0077] The pressing mold is provided with a shaping bump, and the top of the shaping bump is provided with a bump plane area and a bump surface area, and the bump plane area is compatible with the groove bottom plane area, and the bump curve area is compatible with the groove bottom curved surface area match.

[0078] The distance between the flat area of the groove bottom and the flat area of the protrusion is 0.56mm, and the distance between the curved surface area of the groove bottom and the curved surface of the protrusion is 0.67mm. The groove bottom planar area is connected to the groove bottom curved surface area through a step with a depth of 0.055 mm, and the bump flat area is connected ...

Embodiment 3

[0080] A glass forming mold includes a setting mold and a pressing mold used in conjunction.

[0081] The shaping mold is provided with a shaping groove, and the bottom of the shaping groove is provided with a groove bottom plane area and a groove bottom curved surface area;

[0082] The pressing mold is provided with a shaping bump, and the top of the shaping bump is provided with a bump plane area and a bump surface area, and the bump plane area is compatible with the groove bottom plane area, and the bump curve area is compatible with the groove bottom curved surface area match.

[0083] The distance between the flat area of the groove bottom and the flat area of the protrusion is 0.594mm, and the distance between the curved surface area of the groove bottom and the curved surface of the protrusion is 0.61mm. The groove bottom planar area is connected to the groove bottom curved surface area through a step with a depth of 0.008 mm, and the bump flat area is connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com